Kinematics of Common Manipulators

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

2-DOF Planar Robot Arm

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're starting with the 2-DOF planar robot arm. Can anyone tell me what 'Degrees of Freedom' means?

Isn't it the number of independent movements that the robot can make?

Exactly! For our 2-DOF arm, it means we can move in two dimensions. Let’s think of a crane with two joints. What would its movements look like?

It can lift things up and down, and swing them left and right!

Great observation! These movements illustrate FK and IK concepts. Now, let's calculate a simple FK for this arm using trigonometric equations.

How do we even begin calculating that?

We need to know the lengths of our links and the angles of our joints! Remember, for FK, the end-effector position depends on those factors. Can you see how they connect?

Yes! The angles tell us how to position the end-effector.

That's right! Let's summarize: the 2-DOF arm helps us understand basic kinematic principles by focusing on angles and link lengths.

3-DOF SCARA Robot

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, moving on to the 3-DOF SCARA robot. What sets it apart from the 2-DOF arm we've just discussed?

It has more movement options, right? Like vertical movement too?

Exactly! This extra DOF allows SCARA robots to excel in assembly tasks. What do you think this enhancement means for its applications?

It can handle more complex tasks than just moving in two dimensions!

Correct! And by using both revolute and prismatic joints, the SCARA robot demonstrates hybrid behavior. Why do you think that's important in robotics?

It gives robots versatility, right? They can adapt depending on what's needed!

Exactly! As we calculate its FK and IK, let's remember SCARA's efficiency in applications. A quick recap: the SCARA robot combines joint types for versatile functionalities.

6-DOF Industrial Manipulator

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss the 6-DOF industrial manipulator, which is commonly used in advanced robotics. Can someone remind me what this means?

It means it can move in six different ways or dimensions!

Precisely! With six degrees of freedom, it can adapt to complex tasks, like 3D printing. What other applications come to mind?

I recall you mentioning automated bricklaying before!

Exactly! These robots use wrist partitioning to handle the arm and wrist separately. Can anyone explain why we might need to do that?

So we can achieve precise control over positioning and orientation, right?

Yes! Now, let’s summarize: the 6-DOF manipulator enhances versatility, making it suitable for complex applications, while wrist partitioning enhances control.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we discuss the kinematics relevant to common robotic manipulators. We cover the characteristics and kinematic configurations of a 2-DOF planar robot arm for basic understanding, the complex operations of a 3-DOF SCARA robot commonly used in assembly, and the 6-DOF industrial manipulator utilized in advanced applications such as automated bricklaying and 3D printing.

Detailed

Kinematics of Common Manipulators

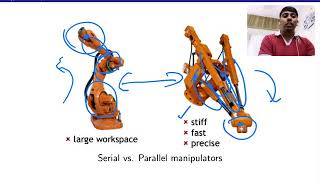

Understanding the kinematics of common manipulators is crucial for robotics, particularly in applications requiring precision and adaptability. In this section, we investigate three prevalent types of robotic arms:

1. 2-DOF Planar Robot Arm

- This simple manipulator serves as an introductory model for kinematic analysis. It utilizes basic trigonometric equations to calculate the forward and inverse kinematics, helping students grasp essential concepts like joint angles and link lengths.

2. 3-DOF SCARA Robot

- The SCARA (Selective Compliance Articulated Robot Arm) robot is widely used in industrial settings for assembly tasks. Its unique combination of revolute and prismatic joints allows for hybrid kinematic performance. This configuration emphasizes the need for a solid understanding of both FK and IK to optimize robotic motion in dynamic environments.

3. 6-DOF Industrial Manipulator

- These sophisticated manipulators find applications in complex tasks such as automated bricklaying, 3D printing, and tunnel excavation. They require advanced kinematic techniques, including wrist partitioning. This involves solving the IK and FK problems separately for the arm and wrist to achieve precise positioning and orientation of the end effector. The section concludes with examples of applications in civil engineering and the critical role of kinematic analysis in enhancing efficiency and accuracy.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

2-DOF Planar Robot Arm

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

10.5.1 2-DOF Planar Robot Arm

- Used for basic theoretical understanding.

- Simple FK and IK derivations with trigonometric equations.

Detailed Explanation

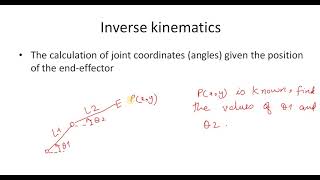

The 2-DOF (Degrees of Freedom) planar robot arm is the simplest form of a robotic manipulator, consisting of two joints allowing for two movement variables. This arm can move in a 2D plane, making it an ideal starting point for students learning about robot kinematics. Forward Kinematics (FK) and Inverse Kinematics (IK) for this type of robot are straightforward as they often rely on basic trigonometric functions. Using angles at each joint, you can deduce the exact position of the end-effector, or conversely, determine the necessary joint angles to reach a specified point in the plane.

Examples & Analogies

Imagine a simple seesaw on a playground that can rotate around its base. The two ends of the seesaw represent the end-effectors of the 2-DOF arm. By adjusting the angle at both ends (the two joints), you can control where a ball placed on the seesaw will roll. This visualization helps understand how adjusting joint angles affects the position of the manipulator.

3-DOF SCARA Robot

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

10.5.2 3-DOF SCARA Robot

- Common in assembly operations.

- Combines revolute and prismatic joints.

- Demonstrates hybrid kinematic behavior.

Detailed Explanation

The 3-DOF SCARA (Selective Compliance Assembly Robot Arm) combines three joints to provide a flexible yet powerful range of motion, typically used in manufacturing and assembly processes. This robot generally includes a mix of revolute joints (which allow rotation) and prismatic joints (which allow linear movement), contributing to its hybrid kinematic behavior. Due to its design, the SCARA arm can reach and manipulate objects within a specific workspace effectively, making it suitable for tasks that require both precision and speed.

Examples & Analogies

Think of a robotic arm like a skilled painter's arm that not only moves side to side but can also stretch to reach taller surfaces or compress to fit into tighter spots. Just like how the painter adjusts their arm for different canvases, a SCARA robot adjusts its joints for various assembly tasks, making it versatile in complex manufacturing environments.

6-DOF Industrial Manipulator

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

10.5.3 6-DOF Industrial Manipulator

- Used in automated bricklaying, 3D printing, and tunneling.

- Complex kinematics with wrist partitioning (solving wrist and arm separately).

Detailed Explanation

The 6-DOF industrial manipulator enables intricate movements in three-dimensional space, making it highly effective for tasks such as bricklaying, 3D printing, and tunneling. With six degrees of freedom, this robot can rotate and position its end-effector at any point within its operational envelope. A key feature of these manipulators is the separation of wrist movement and arm movement, which allows for more complex positioning. Understanding the kinematics of such robots involves accounting for both segments distinctly, which adds to the complexity but enhances functionality.

Examples & Analogies

Imagine a skilled chef who uses both their arms and wrists to create culinary masterpieces. Just as the chef can move their arms to position a pot and then twist their wrist to add ingredients precisely, the 6-DOF manipulator efficiently controls its arm for large movements while using its wrist for fine adjustments to accomplish detailed tasks in manufacturing or construction.

Key Concepts

-

2-DOF Planar Robot: A simple manipulator used for basic kinematic understanding.

-

3-DOF SCARA Robot: Combines revolute and prismatic joints, demonstrating hybrid kinematics.

-

6-DOF Industrial Manipulator: Utilized in complex applications, requiring advanced kinematic techniques.

Examples & Applications

A 2-DOF planar robot is used in basic teaching environments to explain kinematics.

A SCARA robot is commonly found in assembly lines where it assembles electronic components.

A 6-DOF manipulator operates in automated bricklaying for constructing building walls.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In two dof arms, the movements are clear, a simple way to control what’s near.

Stories

Once upon a time in a factory, a SCARA robot danced deftly while assembling parts. Its unique joints allowed it to twist and turn, making assembly a breeze!

Memory Tools

Remember SCARA: 'Saves Cumbersome Assembly and Reduces Anxiety.'

Acronyms

For the 6-DOF manipulator, think of 'RAPID'

'Robotic Arm with Precision In Design.'

Flash Cards

Glossary

- Degrees of Freedom (DOF)

The number of independent movements a robot can make.

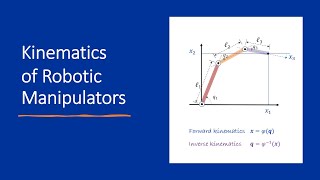

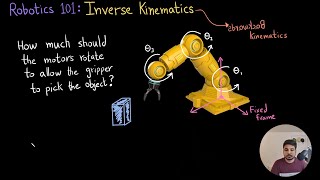

- Forward Kinematics (FK)

The calculation of the position and orientation of a robot's end-effector from given joint parameters.

- Inverse Kinematics (IK)

The determination of joint parameters needed to achieve a desired position and orientation of the end-effector.

- SCARA Robot

A type of robot that combines both revolute and prismatic joints, commonly used in assembly operations.

- Wrist Partitioning

Solving wrist and arm movements separately to enhance control and precision in robotic manipulation.

Reference links

Supplementary resources to enhance your learning experience.