Kinematic Redundancy and Optimization

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Kinematic Redundancy

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss the idea of kinematic redundancy in robotic manipulators. Who can tell me what we mean by kinematic redundancy?

Is it when a robot has more degrees of freedom than needed for a task?

Absolutely right! Kinematic redundancy means a manipulator has extra degrees of freedom that allow for greater flexibility in motion. Can anyone think of a practical benefit of this redundancy?

It could help avoid collisions during tasks, right?

Correct! Avoiding collisions is one of the major advantages. Remember the acronym *F.C.J.S.*—Flexible, Collision avoidance, Joint limit avoidance, and Singular configuration avoidance. This will help you remember the benefits of kinematic redundancy.

Optimization Criteria

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's dive into the optimization criteria that help in planning the robot's movement when redundancy is present. What do you think is one goal of motion optimization?

Minimizing the joint movements to save energy?

Exactly! Minimizing joint displacement is a primary goal. Can someone tell me another optimization approach we might consider?

Maximizing the manipulability index!

Great point! Maximizing manipulability ensures the robot can move efficiently. Now, let’s solidify your understanding: the optimization can be summarized as minimizing a cost function Φ while meeting the forward kinematic equation requirements. Does everyone understand this?

Real-World Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about where these concepts apply in real life. Can anyone name an application in robotics where kinematic redundancy plays a role?

Maybe in robotic arms used for assembly? They might need to avoid obstacles on a production line.

Exactly! Kinematic redundancy allows those robotic arms to adjust while putting various components together. And what about optimization—who can give me an example of its application?

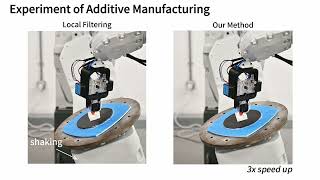

In 3D printing! The printer needs to precisely position its nozzle.

Correct! The optimization process ensures energy-efficient and smooth movements while printing, leading to more effective designs.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Kinematic redundancy occurs when a robot manipulator has more degrees of freedom (DOF) than necessary for a particular task, offering advantages like flexibility and collision avoidance. When optimizing motion, various criteria can be applied, including minimizing joint displacement and maximizing manipulability.

Detailed

Kinematic Redundancy and Optimization

Kinematic redundancy refers to the situation when a robot manipulator possesses more degrees of freedom (DOFs) than are required to perform a given task. This redundancy provides several advantages, including:

- Greater Flexibility: Enables the robot to adapt its configuration to optimize tasks and navigate around obstacles.

- Collision Avoidance: Allows for alternative joint configurations that prevent collisions with the environment.

- Joint Limit Avoidance: Offers more choices in movement while respecting joint constraints.

- Singular Configuration Avoidance: Helps steer clear of configurations that can cause instability in movement.

To effectively utilize this redundancy, optimization criteria need to be applied during the planning of motion trajectories. Common optimization goals include:

- Minimum Joint Displacement: Reducing the movement needed from the joints helps save energy.

- Maximum Manipulability Index: Ensuring motion is efficient in terms of reach and flexibility.

- Energy-efficient Motion Planning: Minimizing energy consumption during motion.

Formally, the optimization problem can be expressed as:

$$\text{min} \Phi(q) \text{ subject to } f(q) = X_d$$

Where:

- Φ(q) is the cost function that may represent energy or joint velocities.

- f(q) corresponds to the forward kinematic equations that yield the desired position of the end-effector, X_d.

These insights into kinematic redundancy and optimization contribute significantly to enhancing robotic performance in various applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Kinematic Redundancy Defined

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A manipulator is kinematically redundant if it has more DOFs than required to perform a task.

Detailed Explanation

Kinematic redundancy refers to a situation in robotic systems where the robot has more degrees of freedom (DOF) than what is necessary to achieve a certain task. This means that there are multiple ways for the robot to achieve the same end goal, allowing for various configurations and paths to get there. For instance, a robot arm with 7 joints may only need to move in 6 dimensions to reach a specific point in space, giving it an extra 'degree' of flexibility.

Examples & Analogies

Think of it like a person trying to reach for a book on a high shelf. If they stretch their arm up, they can get close to the shelf. But if they also climb a little or stand on a chair, they are using more flexibility (or degrees of freedom) than strictly necessary to grab the book. This flexibility can help avoid obstacles, such as other objects on the shelf, just as redundancy in a robotic arm helps avoid collisions with other tools or structures.

Advantages of Redundancy

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Advantages of Redundancy

- Greater flexibility.

- Collision avoidance.

- Joint limit avoidance.

- Singular configuration avoidance.

Detailed Explanation

Kinematic redundancy offers several advantages in robot operations:

- Greater Flexibility: A redundant manipulator can reach the same point in space with different configurations, meaning it can choose paths that minimize strain or avoid certain obstacles is crucial in complex environments.

- Collision Avoidance: With more options available, the manipulator can adjust its position to avoid collisions with other objects, whether they are stationary or moving.

- Joint Limit Avoidance: Redundancy can allow robots to perform tasks without reaching the extreme positions that could lead to joint limits being exceeded.

- Singular Configuration Avoidance: The robot can navigate around configurations that may cause it to lose control or become stuck, thus maintaining stable control of its movements.

Examples & Analogies

Imagine an artist painting a landscape. If they have multiple brushes and colors, they can adjust their techniques easily if an unexpected wind blows some paint off their canvas. Likewise, a redundant robotic arm can shift its position seamlessly to avoid 'winds' or obstacles during a task, ensuring continuous and effective performance.

Optimization Criteria

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Optimization Criteria

- Minimum joint displacement.

- Maximum manipulability index.

- Energy-efficient motion planning.

Optimization is formulated as:

minΦ(q) subject to f(q)=X_d

Where:

- Φ(q) is the cost function (e.g., energy, joint velocity).

- f(q) is the forward kinematic equation.

Detailed Explanation

To make full use of a manipulator's redundancy, optimization techniques are applied. The goal is to refine joint movement in a way that minimizes costs while performing tasks effectively. The criteria for optimization include:

- Minimum Joint Displacement: This aims for the least amount of movement by joint angles, which can help in conserving energy and maintaining precision.

- Maximum Manipulability Index: This measures how easily a manipulator can move in any direction. High manipulability makes it easier to achieve desired positions.

- Energy-efficient Motion Planning: This attempts to execute tasks using the least amount of energy possible, which is crucial for prolonging the life and efficiency of robotic systems.

The optimization can be mathematically expressed as trying to minimize a cost function (Φ(q)), which represents the energy or joint velocity used while ensuring the manipulator reaches a desired end-effector position (X_d).

Examples & Analogies

Think about a professional athlete, like a gymnast. Their goal during a routine is not necessarily just to finish but to do so with minimal movements (like fewer twists and turns), maintain high flexibility to perform different maneuvers seamlessly (max manipulability), and conserve energy for upcoming routines (energy-efficient motion). This analogy reflects how robots optimize their movement paths to achieve tasks with the least effort and maximum efficiency.

Key Concepts

-

Kinematic Redundancy: It allows for greater flexibility and avoids collisions.

-

Optimization Criteria: Establishing goals like minimizing joint displacement and maximizing manipulability.

-

Cost Function: The mathematical representation of the objectives in motion planning.

Examples & Applications

A 7-DOF robotic arm can pick and place objects in a cluttered environment without colliding into obstacles.

In 3D printing, kinematic redundancy helps the printer head make intricate designs efficiently.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In robotics, sunshine and fun, redundancy helps us get the job done!

Stories

Imagine a robot at a busy factory, it spins and twirls, avoiding crates with flair, thanks to its extra joints—it dances through without a care!

Memory Tools

Remember F.C.J.S. for redundancy: Flexibility, Collision avoidance, Joint limit avoidance, Singular avoidance!

Acronyms

R.O.B.O.T

Redundancy Operates Best with Optimized Trajectories.

Flash Cards

Glossary

- Kinematic Redundancy

The condition where a robot has more degrees of freedom than necessary to execute a given task.

- Degrees of Freedom (DOF)

The number of independent variables that define the motion of a robot.

- Optimization Criteria

Parameters considered while planning the motion of a manipulator to improve performance.

- Cost Function (Φ)

A function that quantifies the objective of optimization in robotic motion planning.

- Manipulability Index

A measure of the ability of a robot to move in various directions at a given configuration.

Reference links

Supplementary resources to enhance your learning experience.