Aggregate Grading

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Aggregate Grading

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about aggregate grading. Who can tell me why it's important in concrete?

I think it's about making sure the concrete is strong.

Yes! Aggregate grading helps achieve maximum density and minimizes voids in the mix, which leads to higher strength. Excellent point, Student_1!

How does this actually happen?

Great question, Student_2! Continuous grading allows smaller particles to fill the voids between larger particles, maximizing the packing density. This is crucial for improving both strength and durability of the concrete.

What happens if the grading isn't continuous?

If we have gap grading, which means missing certain sizes of aggregates, we can end up with a lot of voids in the mix. These voids can lead to problems like segregation, where the components separate during mixing. Summarizing, using proper grading ensures we have a more effective mix.

Voids and Density

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive a little deeper into how voids and density affect concrete performance. What do you suppose happens if our mix has too many voids?

It can weaken the concrete, right?

Exactly, Student_4! Too many voids can significantly weaken the overall structure. That’s why we aim for a continuous grading system.

So, how do we determine the right grading?

Excellent inquiry! We often rely on grading curves that show the distribution of aggregate sizes. But we also perform trial mixes to ensure we achieve the desired properties.

How do we know if the grading is effective?

Good question! We can measure workability and look out for segregation. If the concrete mixes well and stays uniform—those are good indicators of proper grading. Let's remember, continuity in grading prevents voids and enhances performance!

Practical Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's discuss practical applications. Where do you think proper aggregate grading would be essential in real-world projects?

In constructing bridges and high-rise buildings due to the loads they have to bear.

Exactly! In structures exposed to extreme loads, achieving maximum density through optimal grading is vital. Any other applications?

I would think marine structures would also need it since they're exposed to harsh conditions.

Great job, Student_2! Marine structures face environmental extremes, and superior aggregate grading can help ensure long-term durability against elements like corrosion. This reinforces the idea that the right grading leads to higher performance and durability in concrete applications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the importance of aggregate grading in High Performance Concrete (HPC), emphasizing the significance of continuous grading to reduce voids and optimize density, which contributes to the overall performance and durability of concrete structures. Proper grading helps avoid segregation and ensures an effective interaction of aggregates with other concrete components.

Detailed

Aggregate Grading in High Performance Concrete

Overview

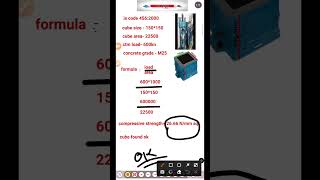

Aggregate grading plays a pivotal role in High Performance Concrete (HPC) mix design. An optimal grading ensures the right particle size distribution, which directly impacts the density and compaction of the mix. Continuous grading is preferred as it minimizes the interstitial voids between aggregates, thereby enhancing the concrete's properties such as strength and durability and reducing the overall water demand. In this section, we will explore the key techniques and concepts surrounding aggregate grading and its significant effect on the performance of HPC.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Continuous Grading

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Continuous grading to ensure minimum voids and maximum density.

Detailed Explanation

Continuous grading of aggregates ensures that the size distribution of the aggregates allows for the least amount of empty space (or voids) between them. This results in a denser concrete mix, which is essential for achieving the desired performance characteristics of High-Performance Concrete (HPC). The more closely the aggregates fit together, the less water and cement are required to fill the gaps, which ultimately leads to stronger concrete.

Examples & Analogies

Think of filling a jar with different sized marbles. If you only use large marbles, you’ll have a lot of empty spaces between them. But if you add smaller marbles into the gaps, you fill those spaces, maximizing the number of marbles you can fit into the jar. This analogy illustrates how properly graded aggregates can fill gaps in the concrete mixture, enhancing density and strength.

Avoidance of Gap Grading

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Avoid gap grading to prevent segregation.

Detailed Explanation

Gap grading refers to using aggregates of certain sizes while omitting others, which can lead to a poor concrete mix. When aggregates are gap-graded, it can cause segregation during mixing and placement, where larger aggregates settle at the bottom and smaller ones rise to the surface. This affects the uniformity and strength of the concrete. To ensure a well-distributed mix, it is critical to use a continuous grading that incorporates a range of aggregate sizes to maintain stability during placement.

Examples & Analogies

Imagine making a fruit salad but only using apples and bananas without including oranges. You would have gaps in your fruit mixture where oranges could have added flavor and texture. In concrete, just like in fruit salad, omitting certain sizes of aggregates results in an incomplete and unstable mixture.

Key Concepts

-

Continuous Grading: A grading method that provides all sizes of particles to improve packing density.

-

Gap Grading: A non-uniform grading that can lead to increased voids and weaker concrete.

-

Voids: Spaces in concrete that can lead to decreased strength if not properly managed.

Examples & Applications

Using continuous grading of aggregates in the mix for a high-rise building ensures high strength and low permeability, critical for structural integrity.

In contrast, using gap grading for a marine structure may lead to increased voids, resulting in premature deterioration due to harsh environmental conditions.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Grading right keeps voids away, strong concrete is here to stay!

Stories

Imagine a builder creating a strong bridge. If they carefully choose every size of stone, it fits perfectly, without gaps, making the bridge steady and lasting. But if they're careless, leaving gaps between stones, the bridge might crumble under pressure.

Memory Tools

Remember the acronym 'C-V-' for Continuous vs. Voids: Continuous reduces voids, leading to stronger concrete.

Acronyms

GAP - Gaps Allow Problems, reflecting the issues caused by improper grading.

Flash Cards

Glossary

- Aggregate Grading

The process of selecting and organizing aggregates in a concrete mix to achieve maximum density and minimum voids.

- Continuous Grading

A grading system where all particle sizes are present and appropriately distributed to fill voids.

- Gap Grading

A grading system that has missing sizes of aggregates, leading to voids in the mixture.

- Voids

Spaces within a material that can weaken its structure if not properly filled.

Reference links

Supplementary resources to enhance your learning experience.