Reactive Powder Concrete (RPC)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to RPC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into Reactive Powder Concrete, commonly known as RPC. Can anyone tell me what differentiates RPC from traditional concrete?

I think it has a different mixture, like finer powders or something?

Exactly! RPC uses very fine powders such as silica fume and quartz. This allows it to achieve exceptional properties. RPC can have compressive strengths between 150 and 800 MPa.

Why is the compressive strength so important for RPC?

That's a great question! The high compressive strength means RPC can be used in highly stressed environments, such as bridges or high-rise buildings. Remember, the term CORED for Compressive strength, Overall durability, Reactivity, and Enhanced performance helps to recall why RPC is beneficial.

CORED! I like that!

To summarize, RPC is characterized by its very fine particle size which leads to high strength and durability. It's essential in modern construction for structures that face extreme conditions.

Properties of RPC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss some properties of RPC. Besides strength, what do you think is crucial for concrete used in harsh environments?

Durability and resistance to water, I guess?

Absolutely! RPC exhibits low permeability, which prevents water and harmful substances from penetrating. This is vital for ensuring long-term performance.

How does RPC compare to regular concrete in terms of durability?

RPC is significantly more durable. Its refined mix protects against freeze-thaw cycles and chemical attack, making it last longer than conventional concrete. Remember the acronym DRIP for Durability, Resistance, Impermeability, and Performance.

DRIP is easy to remember!

Exactly! In summary, RPC's low permeability and high durability make it ideal for structures subject to severe conditions.

Applications of RPC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's explore where RPC is being used. Can anyone list some applications?

I know RPC is used in bridges and maybe tall buildings?

That's correct! RPC is particularly useful in bridges, precast components, and architectural facades. Its strength allows for thinner elements that maintain structural integrity.

What about in areas like marine environments?

Great point! RPC's low permeability makes it resistant to water and chloride intrusion, which is essential in coastal applications. To help remember these applications, think of the acronym BRICK: Bridges, Resilient structures, Industrial components, Coastal applications, and Key precast elements.

I see how useful RPC can be!

To recap, RPC's applications in critical infrastructure showcase its versatility and strength, making it a popular choice in modern engineering.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Reactive Powder Concrete (RPC) showcases remarkable enhancements in compressive strength, achieving levels between 150 MPa to 800 MPa due to the unique blend of materials, including fine powders that allow for a dense and impermeable matrix. Its application is critical in construction projects requiring high durability and low permeability.

Detailed

Reactive Powder Concrete (RPC)

Reactive Powder Concrete (RPC) stands out for its extraordinary compressive strength, ranging from 150 to 800 MPa, far exceeding conventional concrete strengths. This type of concrete employs very fine materials such as silica fume, quartz flour, and other reactive powders without any coarse aggregates. The properties of RPC derive from high packing density achieved through careful mixture proportioning and the use of superplasticizers, which enhance workability.

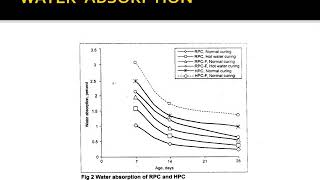

The benefits of RPC include high durability, low permeability, and resistance to environmental impacts, making it suitable for demanding structural applications. RPC structures can withstand extreme loads while exhibiting improved tensile properties, which is crucial in shortening construction timelines and enhancing structural sustainability. Given these properties, RPC is widely used in various advanced construction applications, including bridges, precast components, and architectural elements.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Reactive Powder Concrete (RPC)

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Reactive Powder Concrete (RPC) is a type of concrete known for its exceptionally high strength, ranging from 150 to 800 MPa. It achieves its remarkable strength through the use of very fine powders and the absence of coarse aggregates.

Detailed Explanation

RPC is a specialized form of concrete that possesses extraordinary compressive strength. Unlike conventional concrete that typically uses gravel or coarse aggregates, RPC leverages very fine materials such as silica fume and fine powders. This composition leads to denser concrete with fewer voids and a more refined microstructure, contributing to its strength.

Examples & Analogies

Imagine RPC like a tight-packed jar of marbles where each marble represents a particle in the concrete. The more tightly packed the marbles, the less empty space there is, resulting in a stronger structure. Just like a full jar can withstand more pressure without breaking, RPC's dense composition helps it endure high stress and loads.

Composition of Reactive Powder Concrete

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

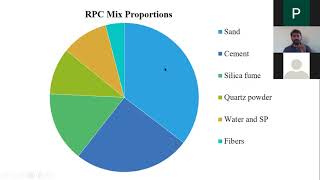

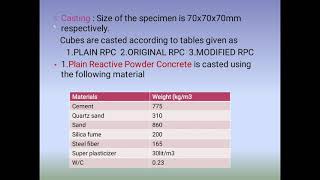

The key to RPC's performance lies in its unique mix design. It typically includes a combination of:

- Very fine powders like silica fume and micro-silica.

- A low water-binder ratio to help reduce porosity.

- Special admixtures to enhance workability and durability.

Detailed Explanation

RPC's exceptional qualities come from its mix composition, which emphasizes the use of fine powders to replace traditional aggregates. By using a low water-binder ratio, RPC minimizes the amount of water in the mix, leading to reduced porosity and increased strength. Additionally, specific chemical admixtures are included to modify the properties of the concrete, allowing it to flow better during placement and improving its durability over time.

Examples & Analogies

Think of RPC as a very fine cake batter where the finer the ingredients, the smoother and denser the cake becomes. Unlike using large chunks of nuts or fruits that might make the cake less stable, RPC avoids using coarse aggregates, ensuring it has the required smoothness and consistency for optimal strength.

Applications of Reactive Powder Concrete

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Due to its remarkable characteristics, RPC is utilized in critical structural applications such as:

- Bridges requiring high load-bearing capacities.

- High-rise buildings where reduced weight is advantageous.

- Thin-walled structures that benefit from its strength-to-weight ratio.

Detailed Explanation

The incredible strength and durability of RPC allow it to be used in various applications where traditional concrete may fail to meet the demands. Bridges, for instance, benefit from RPC because the material can support heavier loads while requiring less overall material. Similarly, in high-rise construction, using RPC can lead to slimmer columns and walls, optimizing space and reducing the building's overall weight.

Examples & Analogies

Consider RPC like a lightweight but very sturdy backpack made from advanced materials. Just as this backpack can carry a heavier load while being light and compact, RPC allows for less material to be used in structural designs while still supporting significant weight, making construction more efficient.

Key Concepts

-

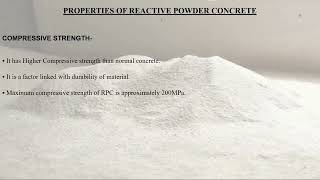

High Compressive Strength: RPC can reach compressive strengths as high as 800 MPa, providing exceptional structural performance.

-

Low Permeability: RPC's unique composition minimizes water penetration, enhancing its durability.

-

Enhanced Durability: RPC is designed for longevity in challenging environments, resisting various deterioration processes.

-

Applications: Widely used in demanding construction contexts such as bridges, high-rise buildings, and precast components.

Examples & Applications

The use of RPC in the construction of the Millau Viaduct in France showcases its ability to support significant loads while maintaining a slender profile.

RPC was utilized in the architectural design of the National Museum of Qatar, where both aesthetic and structural integrity were crucial.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

RPC stands tall, strong like a wall, with fine powders, it beats them all.

Stories

Imagine building a bridge made only of fine dust—RPC that stands the test of time while most would crumble.

Memory Tools

CORED for Compressive strength, Overall durability, Reactivity, Enhanced performance.

Acronyms

BRICK

Bridges

Resilient structures

Industrial components

Coastal applications

Key precast elements.

Flash Cards

Glossary

- Reactive Powder Concrete (RPC)

An advanced type of concrete with very high strength (150–800 MPa) achieved through the use of fine powders instead of coarse aggregates.

- Compressive Strength

The ability of a material to withstand axial loads without failing, often a critical property in concrete.

- Permeability

The property of a material to allow fluids to pass through it, a key property affecting durability in concrete.

- Durability

The capacity of concrete to withstand weathering action, chemical attack, abrasion, and other deterioration processes.

- Silica Fume

A byproduct of silicon production that enhances the properties of concrete when added as a pozzolanic material.

Reference links

Supplementary resources to enhance your learning experience.