Selection of Appropriate Materials

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Material Selection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start discussing why selecting the right materials is essential for High Performance Concrete. What do you think would happen if we used the wrong cement?

I guess it could lead to poor strength or durability?

Exactly! If we choose a cement that isn’t compatible with our admixtures or aggregates, it could result in a mixture that fails to meet our performance specifications. This is why we prioritize compatibility. Does everyone understand what I mean by that?

Kind of! It means the materials should work well together, right?

Yes! We can remember this with the acronym 'C.A.A.S.' which stands for Compatibility, Aggregates, Admixtures, and Strength. Each of these factors contributes to effective HPC design.

Role of Cement and SCMs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s dive deeper into two vital materials: cement and supplementary cementitious materials. Can someone tell me what SCMs are typically used?

I think silica fume is one, right? What else?

Exactly! Silica fume enhances strength and durability. We also use fly ash and GGBS. These materials not only improve performance but also help in sustainability. Why do you think sustainability is important in concrete technology?

Because it helps reduce waste and emissions, I think!

Correct! This emphasis on sustainability is crucial for future developments in concrete technology and makes our HPC mixes more eco-friendly. Great job! Let’s remember this with the acronym 'S.F.G.' for Sustainability, Fly ash, and GGBS.

Aggregates and Admixtures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

We must also discuss the role of aggregates in HPC. Student_1, what characteristics should we look for in aggregates?

They should be high quality and well-graded, right?

Yes! Well-graded aggregates minimize voids and enhance density. Now, what about chemical admixtures? What role do they play?

They help in improving workability and can control setting times?

Exactly! Remember, we can use the mnemonic 'W.C.C.' for Workability, Compatibility, and Control to recall the importance of admixtures in our mixes.

Got it! So, they help our concrete mix behave as we want it to?

Yes! That's a perfect summary.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section highlights the importance of choosing the right combination of cement, supplementary cementitious materials, aggregates, and admixtures for High Performance Concrete. Proper selection ensures the desired performance characteristics and enhances the effectiveness of HPC in demanding applications.

Detailed

Selection of Appropriate Materials

The selection of materials is a foundational element in the design and performance of High Performance Concrete (HPC). Unlike traditional concrete, HPC requires a meticulous approach to ensure compatibility between the various constituents to meet stringent performance requirements. Key components for selection include:

- Cement: Traditional Ordinary Portland Cement (OPC) along with blended types such as Portland Pozzolana Cement (PPC) and Portland Slag Cement (PSC) are essential for achieving desired durability and strength. The compatibility of these cements with other materials is critical.

- Supplementary Cementitious Materials (SCMs): Incorporating materials like silica fume or fly ash enhances strength and durability, making them indispensable to HPC mixes.

- Aggregates: High-quality aggregates with optimal grading and low absorption rates are necessary for minimizing voids and achieving a dense mix, which further enhances durability.

- Chemical Admixtures: The use of superplasticizers and other admixtures can significantly improve workability without sacrificing strength. Their compatibility with chosen cements is vital for maintaining the required performance characteristics.

Through a careful selection of materials, the performance of HPC can be optimized for specific applications, including structures subjected to extreme loads or harsh environments.

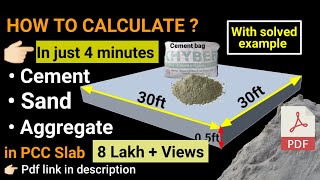

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Material Selection

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Choose compatible combinations of cement, SCMs, aggregates, and admixtures.

Detailed Explanation

In designing high-performance concrete (HPC), it is crucial to select the right materials. This means that the components—cement, supplementary cementitious materials (SCMs), aggregates, and chemical admixtures—must work well together. Compatibility ensures that the overall performance of the concrete meets the desired strength, durability, and workability characteristics.

Examples & Analogies

Think of making a cake. If you want to bake a delicious cake, you must choose ingredients that blend well together, like eggs, flour, sugar, and baking powder. If one of these ingredients is low quality or doesn’t mix well with the others, the cake might not rise, burn, or taste bad. Similarly, in concrete, choosing incompatible materials can lead to problems like cracking or reduced strength.

Cement Selection

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Use of Ordinary Portland Cement (OPC) Grade 43 or 53. Blended cements like Portland Pozzolana Cement (PPC) or Portland Slag Cement (PSC) are also used for durability. Compatibility with admixtures is crucial.

Detailed Explanation

When selecting cement for HPC, Ordinary Portland Cement (OPC) of grades 43 or 53 is commonly used because of their strength and reliability. Additionally, blended cements like Portland Pozzolana Cement (PPC) or Portland Slag Cement (PSC) are preferred for their enhanced durability, especially in environments exposed to harsh conditions. It's essential that the chosen cement is compatible with any chemical admixtures added to the mix, as this can affect the setting time and overall performance of the concrete.

Examples & Analogies

Imagine a team playing soccer where each player has a specific role. If the forward and defender don't communicate or understand each other’s strengths, the game can go poorly. In concrete, cement acts as one of the key players, and ensuring it works well with admixtures (other teammates) is what makes the performance successful.

Supplementary Cementitious Materials (SCMs)

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Silica Fume: Enhances strength and durability, used in 5–10% replacement. Fly Ash: Improves workability and long-term strength. Ground Granulated Blast Furnace Slag (GGBS): Enhances durability and reduces heat of hydration.

Detailed Explanation

Supplementary Cementitious Materials (SCMs) play a vital role in improving the properties of HPC. Silica fume, for example, is a very fine material that significantly increases concrete's strength and durability when used as a 5-10% replacement for cement. Fly ash helps with workability and contributes to long-term strength development. Ground Granulated Blast Furnace Slag (GGBS) not only enhances durability but also helps to reduce the heat released during the hydration process, which can be particularly important in large pours of concrete.

Examples & Analogies

Think of SCMs as secret ingredients in your favorite dish. Just as adding a pinch of salt or a dash of seasoning can enhance the flavor of a meal, adding SCMs can significantly boost the performance of concrete, making it stronger and more durable over time.

Aggregate Selection

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

High-quality, well-graded coarse and fine aggregates. Low water absorption and minimal deleterious materials. Maximum aggregate size typically 10–20 mm for HPC.

Detailed Explanation

The selection of aggregates is crucial for achieving high-performance concrete. Aggregates should be of high quality and well-graded, meaning there's a good mix of different sizes to minimize voids and maximize density. Low water absorption is essential to ensure the aggregates do not absorb too much water from the mix, which could compromise the concrete's integrity. For HPC, the maximum size of aggregates typically ranges between 10 mm to 20 mm to ensure proper workability and strength.

Examples & Analogies

Imagine building a wall where the shape and size of the bricks matter. If they are uneven or of poor quality, the wall won’t be strong and may crack. Similarly, in concrete, the aggregates (the 'bricks') must be selected carefully to ensure the 'structure' holds together firmly and withstands various stresses.

Chemical Admixtures

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Superplasticizers (High Range Water Reducers): Essential for achieving high workability without increasing water content. Retarders: To control setting time. Accelerators: For early strength. Viscosity Modifying Agents (VMAs): For pumpability and stability in SCC (Self-Compacting Concrete).

Detailed Explanation

Chemical admixtures are added to concrete to modify its properties in specific ways. Superplasticizers allow for high workability without needing extra water, which is vital for achieving strength and durability. Retarders can slow the setting time, which is useful in hot weather conditions, while accelerators help in gaining early strength. Viscosity Modifying Agents (VMAs) are especially helpful for self-compacting concrete, ensuring it flows smoothly and does not segregate.

Examples & Analogies

Think of chemical admixtures as the spices in cooking that adjust texture and flavor. Just as you might use a special spice to enhance the dish's quality or to control how it cooks, admixtures help fine-tune the performance of concrete, ensuring it meets the specific needs of each project.

Water Quality and Quantity

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Potable quality water with no harmful salts or organic impurities. Water-cement ratio as low as 0.25–0.35.

Detailed Explanation

The quality of water used in mixing concrete is critical. Only potable quality water should be used because any harmful salts or organic impurities can negatively affect the chemical reactions during curing, leading to potential weakening of the concrete. The water-cement ratio is also a key parameter; a lower ratio, typically between 0.25 and 0.35, helps improve strength and reduces permeability. However, it needs to be balanced to maintain workability.

Examples & Analogies

Consider how the quality of water can affect your hydration. Drinking clean, safe water helps you stay healthy and functions better, while contaminated water can cause illness. Similarly, using clean water in concrete ensures the mix behaves as expected and develops the strength and properties necessary for high performance.

Key Concepts

-

Material Compatibility: Ensuring that cement, aggregates, and admixtures work well together.

-

Supplementary Cementitious Materials (SCMs): Key materials to improve the properties of HPC.

-

Well-Graded Aggregates: Important for reducing voids and enhancing the mix's density.

-

Chemical Admixtures: Substances that adjust the properties of concrete to optimize performance.

Examples & Applications

Using silica fume in a concrete mix to increase its compressive strength.

Selecting fly ash as an SCM to enhance workability and reduce permeability in HPC.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When selecting materials, keep quality in line, / Choose cement and aggregates that intertwine.

Stories

Once there were four ingredients in a concrete pot, / Each played a role in making it hot. / Cement stood strong, the SCMs gave might, / Aggregates and admixtures made everything right.

Memory Tools

C.A.A.S. - Remember Compatibility, Aggregates, Admixtures, Strength when selecting materials.

Acronyms

S.F.G. - Sustainability, Fly ash, and GGBS are key to modern concrete mixes.

Flash Cards

Glossary

- High Performance Concrete (HPC)

Concrete that exhibits superior properties such as high strength, durability, and reduced permeability compared to conventional concrete.

- Supplementary Cementitious Materials (SCMs)

Materials added to concrete to improve its properties, such as silica fume and fly ash.

- Chemical Admixtures

Substances added to the concrete mix to alter its properties, e.g., superplasticizers to enhance workability.

- WellGraded Aggregates

Aggregates of various sizes that minimize voids, thus improving the density and performance of concrete.

- Compatibility

The ability of materials, such as cement and admixtures, to function effectively together in a concrete mix.

Reference links

Supplementary resources to enhance your learning experience.