High Performance Concrete

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to High Performance Concrete

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore High Performance Concrete, or HPC, which is a major advancement over conventional concrete. Can anyone tell me the key differences between HPC and normal concrete?

I think HPC is stronger than normal concrete.

HPC also lasts longer under extreme conditions, right?

Absolutely! HPC typically has compressive strengths above 60 MPa and lower permeability, crucial for durability. Just remember the acronym **SPEED** for its properties: Strength, Permeability, Elasticity, Durability!

What about workability? How does that change?

Great question! HPC uses superplasticizers to improve workability while reducing water content. Let’s move on to the materials used in HPC.

Materials Used in High Performance Concrete

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

HPC is made with specific materials. Can anyone name the types of cement used?

Ordinary Portland Cement and blended cements like Portland Pozzolana Cement?

Right! We also have supplementary cementitious materials like silica fume and fly ash, which enhance strength and durability. What’s the role of these materials in the mix?

They help fill voids in the mix?

Exactly! This aids in optimizing particle packing. Don't forget the mnemonic **CATS**: Cements, Aggregates, Tests, and SCMs!

Principles of Mixture Proportioning

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss the principles of mixture proportioning for HPC. What do we need to consider?

We need to define target performance specifications.

Great! Specifying desired strength and workability is crucial. Also, we have to look at aggregate grading and water-binder ratios. Does anyone remember the typical ratio?

Isn’t it usually around 0.25 to 0.35?

Correct! Keep that in mind. Always aim for the maximum density and minimized voids using **GROOVY**: Grading, Ratio, Optimized packing, Origin materials, Viscosity control, Yield expectations.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

High Performance Concrete (HPC) differs from conventional concrete through its exceptional strength, reduced permeability, and increased durability. This section explores its properties, mixture proportioning, materials involved, and the principles behind its design, emphasizing its critical role in demanding construction projects.

Detailed

High Performance Concrete (HPC)

High Performance Concrete (HPC) signifies a technological leap in concrete with characteristics such as high compressive strength often exceeding 60 MPa, low permeability, and exceptional durability against environmental effects. The attributes of HPC make it suitable for critical applications like bridges and marine structures. The performance of HPC is heavily dependent on the careful selection of constituents and precision in mixture proportioning.

Key Characteristics

The properties that define HPC include high compressive strength, low permeability, enhanced durability, improved workability, early strength gain, controlled heat of hydration, high modulus of elasticity, and low creep.

Materials Used in HPC

Materials for HPC are carefully selected, spanning several categories including cement types (Ordinary Portland Cement, blended cements), supplementary cementitious materials (like silica fume and fly ash), high-quality aggregates, chemical admixtures (superplasticizers, retarders, accelerators), and potable water.

Principles of Mixture Proportioning

The mixture design follows performance-based principles, focusing on target strength, water-binder ratio, and optimizing particle packing while ensuring workability.

Special Types of HPC

Different variants include Self-Compacting High Performance Concrete (SCHPC), Reactive Powder Concrete (RPC), and Fiber-Reinforced HPC, each having unique properties tailored for specific structural needs.

Challenges and Quality Control

HPC works require stringent quality checks at every production stage to ensure consistency and desired performance outcomes. Identifying challenges in material compatibility, mixing, and workability retention is crucial for successful implementation.

Applications and Innovations

The research on HPC continues to evolve with advancements such as nanomaterials and AI integration in mix design processes, focusing on efficiency and sustainability.

Youtube Videos

![High Performance Concrete [HPC]-2/CT M5 V10](https://img.youtube.com/vi/E3GobQv7cgE/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to High Performance Concrete (HPC)

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

High Performance Concrete (HPC) represents a significant advancement in the field of concrete technology. Unlike conventional concrete, HPC offers superior properties such as high strength, enhanced durability, reduced permeability, and resistance to environmental aggressors. Its use is crucial in structures exposed to extreme loads or harsh environments, such as bridges, high-rise buildings, marine structures, and nuclear containment systems.

Detailed Explanation

High Performance Concrete, or HPC, is a special blend of materials designed to perform better than traditional concrete. It is engineered to be stronger, last longer, and resist damage from environmental conditions like moisture, extreme temperatures, and chemicals. While regular concrete works well for many construction projects, HPC is specifically chosen for critical structures like bridges and skyscrapers where performance is key.

Examples & Analogies

Think of HPC like a high-performance car. Just as a regular car can get you from point A to point B, HPC ensures that structures endure more stress and environmental challenges, similar to how a sports car handles winding roads and high speeds better than a sedan.

Key Characteristics of HPC

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

High Performance Concrete is designed to meet specific performance requirements that are not achievable with conventional concrete. Key characteristics include:

- Compressive Strength: Typically exceeding 60 MPa, and in some cases going beyond 100 MPa.

- Low Permeability: Minimizes ingress of chlorides, sulfates, and other aggressive agents.

- High Durability: Resistance to freeze-thaw cycles, alkali-silica reaction, and chemical attacks.

- Improved Workability: Achieved with the use of superplasticizers and optimized aggregate grading.

- Early Strength Gain: Facilitates faster formwork removal and rapid construction.

- Controlled Heat of Hydration: Especially in mass concrete applications.

- High Modulus of Elasticity and Low Creep: Ensuring minimal long-term deformations.

Detailed Explanation

HPC has several important characteristics that make it unique. It can handle very high loads (compressive strength) and has a low ability for water and chemicals to penetrate (low permeability). This means it lasts longer. Additionally, HPC can work better during mixing and placement due to improved flow and mixture (workability). It can also speed up construction since it gains strength quickly, which is especially useful for large projects, and it helps prevent long-term bending or deformation.

Examples & Analogies

Think of HPC as a super-strong shield for buildings. Just like how certain materials can easily protect you from impacts or elements, HPC protects structures from external pressures and harsh conditions, ensuring that the buildings remain intact and safe for years.

Materials Used in HPC

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

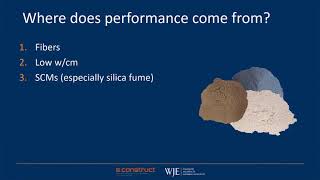

- Cement

- Use of Ordinary Portland Cement (OPC) Grade 43 or 53.

- Blended cements like Portland Pozzolana Cement (PPC) or Portland Slag Cement (PSC) are also used for durability.

- Compatibility with admixtures is crucial.

- Supplementary Cementitious Materials (SCMs)

- Silica Fume: Enhances strength and durability, used in 5–10% replacement.

- Fly Ash: Improves workability and long-term strength.

- Ground Granulated Blast Furnace Slag (GGBS): Enhances durability and reduces heat of hydration.

- Metakaolin, Rice Husk Ash, and Alccofine are also used for specific performance targets.

- Aggregates

- High-quality, well-graded coarse and fine aggregates.

- Low water absorption and minimal deleterious materials.

- Maximum aggregate size typically 10–20 mm for HPC.

- Chemical Admixtures

- Superplasticizers (High Range Water Reducers): Essential for achieving high workability without increasing water content.

- Retarders: To control setting time.

- Accelerators: For early strength.

- Viscosity Modifying Agents (VMAs): For pumpability and stability in SCC (Self-Compacting Concrete).

- Water

- Potable quality water with no harmful salts or organic impurities.

- Water-cement ratio as low as 0.25–0.35.

Detailed Explanation

Creating HPC begins with selecting the right materials. It typically uses high-grade cement and blends that enhance performance. Supplementary Cementitious Materials like silica fume and fly ash are added for strength and durability. The aggregates must be of high quality to ensure consistency in performance. Chemical admixtures enhance the mixture's workability and controlation of setting times, and it's essential to use clean water that doesn't contain harmful impurities. The careful balance of these materials contributes to the overall performance of the concrete.

Examples & Analogies

Think of the materials in HPC as ingredients in a gourmet recipe. Just as a chef carefully selects the best spices, meats, and vegetables to enhance a dish's flavor, engineers choose high-quality materials to ensure that HPC provides optimal performance in construction.

Principles of Mixture Proportioning for HPC

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Designing HPC requires a performance-based approach. The major principles include:

1. Target Performance Specification

- Define the properties required in fresh and hardened states: strength, slump, setting time, durability, etc.

2. Selection of Appropriate Materials

- Choose compatible combinations of cement, SCMs, aggregates, and admixtures.

3. Optimization of Particle Packing

- Use of fine materials (silica fume, fly ash, etc.) to fill voids between cement grains.

- Improves density and reduces porosity.

4. Water-Binder Ratio

- Lower w/b ratio (typically 0.25–0.35) ensures low permeability and high strength.

- Must be balanced with the workability requirements.

5. Aggregate Grading

- Continuous grading to ensure minimum voids and maximum density.

- Avoid gap grading to prevent segregation.

6. Use of Admixtures

- Superplasticizers are used to reduce water demand without affecting workability.

- VMAs may be used where segregation is an issue.

7. Trial Mixes

- Essential for validating lab designs under real conditions.

- Adjustment based on setting time, slump, strength, and durability indicators.

Detailed Explanation

The mixture proportioning of HPC is carefully planned to achieve the desired performance. It starts with defining what kind of performance is necessary for the concrete, including how strong and durable it needs to be. Then appropriate materials are chosen and combined in ways that maximize their performance benefits. By optimizing how particles combine, using lower water-binder ratios to create stronger mixes, and ensuring aggregates are correctly graded, engineers can create a blend that produces high-performance concrete. Finally, they conduct trial mixes to check that the desired properties are actually achieved under realistic conditions.

Examples & Analogies

Imagine baking a cake. First, you decide how you want it to taste and look. Then, you carefully choose your ingredients based on that desired outcome, measuring everything precisely to ensure it rises correctly and has the right texture. Testing it out with a smaller batch lets you see how it turns out before making the final cake, which is similar to trial mixes in concrete.

Durability Considerations in HPC Proportioning

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Durability is a critical component in HPC mix design:

- Permeability: Controlled by lowering the w/b ratio and densifying the matrix.

- Chloride Penetration Resistance: Improved with silica fume and fly ash.

- Sulfate Resistance: Use of low C3A cement and pozzolanic materials.

- Carbonation Resistance: Dense matrix and cover depth are key.

- Freeze-Thaw Resistance: Use of air entrainment if necessary in cold climates.

Detailed Explanation

Durability ensures that HPC can withstand real-world conditions without breaking down. By manipulating the mix, such as reducing the water-binder ratio and enhancing the density of the concrete, engineers can significantly lower permeability, preventing water and aggressive chemicals from damaging the concrete. The use of certain materials, like silica fume, improves resistance to chlorides and sulfates. Additionally, attention to the density of the concrete and how it covers reinforcing materials protects against environmental issues like carbon dioxide penetration and freeze-thaw cycles particularly in cold climates.

Examples & Analogies

Think of the importance of durability like having a well-made winter jacket. A good jacket keeps you warm and dry by blocking water and wind (similar to how low permeability in concrete prevents damage). If your jacket is well-made with quality materials, it can resist harsh winter conditions, just like how durable HPC is designed to endure various damaging environmental factors.

Key Concepts

-

High Strength: HPC typically exceeds 60 MPa and provides improved structural performance.

-

Low Permeability: Reduces the chance of chemical ingress, enhancing durability.

-

Durability: Greater resistance to environmental stressors, including freeze-thaw cycles and chemical attacks.

-

Mixture Proportioning: HPC requires specific methods for optimal performance due to its complex composition.

Examples & Applications

High Performance Concrete is used in structures like the Burj Khalifa for vertical structures.

The Bandra-Worli Sea Link utilized HPC for its marine exposure, requiring low permeability and high durability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

HPC, oh can't you see, strong and durable it should be!

Stories

Once there was a construction worker building a castle by the sea, he knew that only High Performance Concrete would keep it safe from the salty waves.

Memory Tools

To remember the key materials for HPC, think of CATS: Cement, Aggregates, Tests, and Supplementary materials.

Acronyms

Remember **SPEED** to recall the characteristics of HPC

Strength

Permeability

Elasticity

Durability.

Flash Cards

Glossary

- High Performance Concrete (HPC)

Concrete that exhibits superior properties such as high strength, durability, and low permeability.

- Compressive Strength

The capacity of a material to withstand axial loads without failure, often measured in MPa.

- WaterBinder Ratio

The ratio of the mass of water to the mass of cement in a concrete mix, crucial for determining strength and durability.

- Supplementary Cementitious Materials (SCMs)

Materials used in conjunction with cement to enhance the performance of concrete.

- Particle Packing

The arrangement of particles in a mixture which affects the density and void content.

Reference links

Supplementary resources to enhance your learning experience.