Hot Weather and Cold Weather Concreting

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Challenges of Hot Weather Concreting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we're going to discuss how hot weather affects concrete placement. Can anyone tell me why cooling the materials is important?

I think it's to prevent the concrete from setting too quickly?

Exactly! Rapid hydration can occur, leading to cracks. Using chilled water or ice can reduce this risk. What other methods can we employ?

We can try to place the concrete at cooler times of the day.

Right! It's crucial to time our work effectively in hot weather. Remember the acronym C.H.A.T. – Cool materials, Hot Times consideration, Avoid delays, Timely placement. Let’s summarize: cooling the materials and managing timing are key strategies.

Strategies for Cold Weather Concreting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s turn our attention to cold weather concreting. What do you think we should do with the concrete materials in freezing conditions?

Maybe we should heat them up before mixing?

That’s correct! Preheating aggregates and water can help maintain the temperature. What about accelerators?

They can help the concrete set faster in the cold, right?

Exactly! Additives like set accelerators can dramatically improve strength gain. Remember the phrase H.O.P.E. – Heat aggregates, Optimize placement, Prevent freezing, Employ accelerators. Let’s conclude: preheating and using accelerators are essential in colder climates.

Curing Techniques in Extreme Weather

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Curing is vital in both hot and cold climates. Can anyone recall some curing methods that can be effective?

For hot weather, we should probably use wet burlap or membrane curing.

Great point! Membrane curing helps retain moisture. What about cold weather?

I imagine methods that keep the concrete warm, like using insulated blankets?

Absolutely! Insulation can protect against freezing. Remember the mnemonic C.A.R.E – Control temperature, Apply moisture, Retain heat, Evaluate conditions.

This helps ensure the concrete sets properly, right?

Exactly! Proper curing is crucial to maintain strength and prevent damage. Let’s summarize: effective curing techniques differ by weather but always retain heat and moisture.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Effective concreting in extreme weather conditions requires specific strategies. In hot weather, materials should be cooled and placement should be timed to reduce slump loss, while in cold weather, materials may need preheating and set accelerators for proper curing.

Detailed

Hot Weather and Cold Weather Concreting

Proper placement and curing techniques are crucial for achieving desired performance in High Performance Concrete (HPC) structures, especially in varying temperatures. This section explores specific strategies to mitigate the effects of extreme weather conditions on HPC placement and curing.

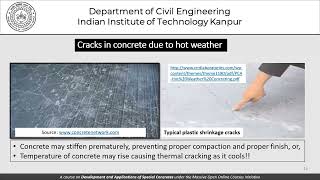

Hot Weather Concreting

- Cooling Materials: In hot climates, using chilled water or ice flakes can help maintain the desired temperature of the mix, reducing the risk of rapid hydration that can compromise the strength and durability of the concrete.

- Timely Placement: Delay casting if possible until cooler parts of the day to avoid heat-related issues. Immediate transportation to the job site is essential to prevent slump loss, ideally within 60 minutes.

Cold Weather Concreting

- Preheating Materials: In colder climates, especially in freezing temperatures, it is advisable to preheat aggregates and water to ensure proper curing. Keeping the concrete temperature above 5°C during the curing period is critical.

- Use of Accelerators: Set accelerators should be added to the mix to promote faster strength gain, allowing the concrete to set and cure effectively despite lower ambient temperatures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Hot Weather Concreting Techniques

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In hot climates: Use chilled water or ice flakes, and delay casting.

Detailed Explanation

In hot weather, the temperature can significantly affect the hydration process of concrete, causing it to set too quickly. To manage this, construction teams can take specific steps. One effective method is to use chilled water or ice flakes in the concrete mix. This reduces the temperature of the mix, slowing down the chemical reactions in the concrete and preventing it from curing too fast. Additionally, it may sometimes be beneficial to delay the casting of the concrete until temperatures drop, such as later in the day or at night when it is cooler.

Examples & Analogies

Think of making ice cream on a hot summer day. If you make it outside in the sun, it might melt too quickly and not freeze properly. But if you keep your ingredients chilled, you can make a better ice cream that holds its shape longer. Similarly, using chilled water or ice in concrete helps maintain its integrity in hot weather.

Cold Weather Concreting Techniques

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In cold climates: Preheat materials or use set accelerators.

Detailed Explanation

Cold weather poses unique challenges for concrete curing. In low temperatures, concrete can set too slowly, which can lead to problems such as freezing before it has cured properly. To combat this, construction teams may preheat the materials, such as the water and aggregates, before mixing them. This adds warmth to the overall mixture. Alternatively, set accelerators can be added to the mix. These chemical additives speed up the curing process, allowing the concrete to set and gain strength more quickly, even in cold temperatures.

Examples & Analogies

Consider baking bread during winter. If the dough is cold, it may take longer to rise. To fix this, bakers often warm the ingredients or put the dough in a warm spot. In the same way, preheating concrete ingredients or using accelerators helps it 'rise' and set faster in cold weather.

Key Concepts

-

Cooling Materials: Necessary in hot weather for better hydration.

-

Preheating: Important in colder climates to ensure temperature control.

-

Use of Accelerators: Essential during cold weather to enhance strength gain.

-

Curing Techniques: Varies by weather; involves methods to retain moisture and temperature.

Examples & Applications

In hot conditions, a construction team uses chilled water to maintain the temperature of their concrete mix, preventing quick evaporation.

In winter, a contractor preheats the water and aggregates before mixing to keep the concrete from freezing, allowing it to set properly.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In hot weather, keep it cool, use ice, that's the rule!

Stories

Imagine a construction site where the sun is blazing. Workers use ice in their water and pour in the cool of the evening to keep their concrete in top shape - a method learned through experience.

Memory Tools

Remember the acronym C.H.A.T. for hot weather: Cool materials, Hot times, Avoid delays, Timely placement.

Acronyms

H.O.P.E. for cold weather

Heat the materials

Optimize placement

Prevent freezing

Employ accelerators.

Flash Cards

Glossary

- Hot Weather Concreting

Concrete placement and curing processes adapted to high ambient temperatures.

- Cold Weather Concreting

Concrete placement and curing processes adapted to low ambient temperatures.

- Preheating

The method of warming concrete materials before mixing to maintain temperature.

- Set Accelerators

Admixtures used in cold weather to speed up the setting process of concrete.

- Membrane Curing

A method of curing that involves covering the surface of fresh concrete to retain moisture.

- Curing

The process of maintaining adequate moisture and temperature in concrete for hydration.

Reference links

Supplementary resources to enhance your learning experience.