Water-Binder Ratio

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Water-Binder Ratio

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we're discussing the water-binder ratio in high performance concrete, or HPC. Can anyone tell me why this ratio is important?

I think it affects how strong the concrete is?

That's right, Student_1! The water-binder ratio impacts the compressive strength, workability, and overall durability of the concrete.

What’s a typical range for the water-binder ratio in HPC?

Great question, Student_2! A typical range is 0.25 to 0.35. Why do you think keeping it low is beneficial?

I think it reduces permeability.

Exactly! Lowering the w/b ratio helps create a denser microstructure, enhancing durability.

Does that mean we can just reduce the water as much as possible?

Good point, Student_4! We must balance strength and workability, because too little water can make the mix hard to handle.

In summary, the water-binder ratio is crucial for strength and durability but needs to be balanced with workability.

Effects of Water-Binder Ratio on Properties

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about how changes in the water-binder ratio influence different properties of HPC. Who would like to start us off?

I remember you said it can increase compressive strength?

Yes! Lowering the w/b ratio generally increases strength. Can anyone tell me why?

Because it makes the concrete denser?

Exactly! A denser structure means fewer voids for harmful substances to enter. What about workability?

It's harder to mix if there's less water, right?

Correct! Reducing water lowers workability, which can be a challenge. What might we do to address that?

Maybe use superplasticizers to help with mixing?

That's an excellent solution, Student_4! Superplasticizers can enhance workability at lower water contents.

To summarize: while lowering the water-binder ratio enhances strength and durability, it requires careful management of workability.

Practical Applications of Water-Binder Ratio

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s consider the practical implications of our water-binder ratio decisions. When might we choose a higher w/b ratio?

Maybe in areas where the concrete doesn’t face extreme conditions?

Exactly! For less critical applications, we might prioritize workability over strength, allowing for a slightly higher ratio.

What about the environmental impact? Does it matter?

It does! Using a lower w/b ratio can reduce permeability to environmental aggressors, extending the lifespan of structures. What are some examples of structures that might need a low w/b ratio?

Like bridges or skyscrapers?

Precisely! Those structures experience high loads and need high durability. As a recap, selecting the appropriate water-binder ratio balances strength, workability, and environmental considerations.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In high performance concrete, the water-binder ratio significantly affects its properties. A low water-binder ratio (typically 0.25 to 0.35) enhances strength and minimizes permeability, but it must be balanced with workability. This section discusses the importance of this ratio in achieving the desired performance characteristics for various applications.

Detailed

Water-Binder Ratio

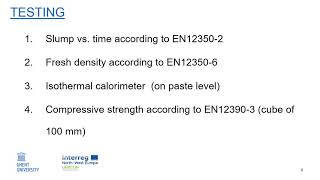

The water-binder (w/b) ratio is paramount in the production of high performance concrete (HPC), correlating directly to several of its key properties such as strength, workability, and durability. In HPC, the ideal w/b ratio is typically maintained between 0.25 and 0.35, which promotes low permeability while ensuring high compressive strength. A lower w/b ratio not only improves the density of the concrete but also minimizes its susceptibility to environmental factors.

Importance of Water-Binder Ratio

- Strength Enhancement: Lowering the w/b ratio generally leads to increased compressive strength, typically exceeding 60 MPa in HPC applications.

- Workability vs. Strength Balance: It is crucial to find a balance between maintaining low w/b ratios and achieving satisfactory workability, especially in complex shapes or densely reinforced areas.

- Durability: A lower ratio fosters a denser microstructure, which is essential for durable concrete that can withstand harsh environments, thereby reducing the likelihood of cracking and degradation over time.

Conclusion

Overall, meticulous attention to the water-binder ratio during the mixture design process plays an integral role in ensuring the high performance attributes of concrete are achieved, making it suitable for critical structural applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Water-Binder Ratio

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Lower w/b ratio (typically 0.25–0.35) ensures low permeability and high strength.

Detailed Explanation

The water-binder (w/b) ratio is a fundamental aspect of concrete mix design, particularly for High Performance Concrete (HPC). A lower w/b ratio typically ranges from 0.25 to 0.35. This means that for every one part of binder material (which includes cement and supplementary cementitious materials), there are only 0.25 to 0.35 parts of water. This lower amount of water leads to a denser concrete matrix, which reduces the number of voids in the hardened concrete. Consequently, this significantly lowers the permeability of the concrete, making it less susceptible to water leakage and environmental damage, while also enhancing its overall strength.

Examples & Analogies

Think of the w/b ratio like making a thick smoothie versus a watery one. If you use less water (similar to a lower w/b ratio), the smoothie is richer and thicker, filled with more fruits and nutrients (the binder). In the same way, reducing water in a concrete mix creates a stronger, denser material that can withstand greater stresses.

Balancing Workability and Strength

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Must be balanced with the workability requirements.

Detailed Explanation

While a lower water-binder ratio contributes to high strength and low permeability, it's essential to balance this with workability—the ease with which concrete can be mixed, placed, and finished. High-performance concrete still needs to be workable enough for proper application, such as pouring and molding. If the ratio is too low, the mixture could become too stiff and unmanageable, making it difficult to work with. Therefore, engineers must find an equilibrium between achieving the desired strength through a lower w/b ratio while ensuring that the concrete remains workable for construction purposes.

Examples & Analogies

Imagine making cookie dough. If you add too much flour (analogous to having a very low w/b ratio), the dough becomes hard and difficult to roll out, resulting in tough cookies. But if you add too much milk, the dough becomes too runny and can’t be shaped properly. A good cookie recipe finds the right balance of ingredients, just like engineers must balance water and binder in concrete.

Key Concepts

-

Water-Binder Ratio: A key ratio affecting the properties of concrete, particularly strength and durability.

-

Compressive Strength: The ability of the concrete to withstand axial loads without failure, enhanced by lower w/b ratios.

-

Workability: The ease of mixing, placing, and finishing the concrete, which decreases with lower w/b ratios.

Examples & Applications

A typical water-binder ratio for HPC is maintained between 0.25 to 0.35 to achieve high strength.

In bridge constructions, a lower w/b ratio minimizes permeability, protecting against chlorides.

Using superplasticizers allows for high strength concrete with low water content while maintaining workability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For strength in the mix, keep water low, 0.25 to 0.35 is the way to go.

Stories

Imagine a bridge built strong and tall with concrete dense, it stands against the storms, protected by its low w/b fence.

Memory Tools

HPC's w/b: 2-5-3 (0.25 to 0.35) makes it tough — think 'strength and durability are enough!'

Acronyms

P.E.A.C.E

Permeability

Endurance

And Compressive Strength Enhance with lower w/b.

Flash Cards

Glossary

- WaterBinder Ratio

A proportion of water to the total binder (cement + supplementary cementitious materials) to achieve desired concrete properties.

- High Performance Concrete (HPC)

Concrete that is engineered to achieve superior performance characteristics in terms of strength, durability, and workability.

- Permeability

The ability of materials to allow fluids to pass through, a critical factor in concrete durability.

Reference links

Supplementary resources to enhance your learning experience.