Materials for HPC

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Cement in HPC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will discuss the role of cement in HPC. What types of cement are most commonly used?

Is it just Ordinary Portland Cement?

Good question, Student_1! We primarily use Ordinary Portland Cement, but we also incorporate blended cements like Portland Pozzolana Cement and Portland Slag Cement for their durability benefits.

Why is compatibility with admixtures important?

Great note, Student_2! Compatibility ensures that the cement works effectively with other materials to achieve high strength and durability. Think about the acronym 'CCCP': Compatibility, Composition, Cost, Performance.

What about the different grades of cement?

Yes, Student_3! Ideally, we use Grade 43 or 53 OPC; higher grades yield better performance.

Supplementary Cementitious Materials

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on to Supplementary Cementitious Materials, what do you think their purpose is?

They must improve the concrete somehow?

Exactly, Student_4! Materials like silica fume enhance strength and durability. For example, we use 5-10% silica fume to significantly improve durability against harsh environments.

What about fly ash; how does it help?

Excellent point! Fly ash not only improves workability but also enhances long-term strength. Remember the mnemonic 'Sandy Flies Fly': Silica for strength, Fly for workability.

And GGBS?

Ground Granulated Blast Furnace Slag is fantastic for reducing heat of hydration and enhances overall durability. So, adding these SCMs significantly results in a robust concrete mix!

Selecting Aggregates for HPC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about aggregates. What do you think makes aggregate quality important in HPC?

Because they are a major part of the concrete mix, right?

Exactly, Student_3! We need high-quality and well-graded aggregates to achieve optimal performance. They should have low water absorption and minimal deleterious materials.

What size aggregates should we use?

Typically, we use aggregates sized between 10 to 20 mm, but what's the impact of size on performance?

Smaller aggregates might allow for better packing?

Yes, and remember the term 'Density and Strength'. A well-graded aggregate mix contributes to a dense concrete mix!

Importance of Chemical Admixtures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's explore chemical admixtures. Can anyone name a type of chemical admixture used in HPC?

Superplasticizers, right?

That's correct! Superplasticizers are essential for achieving high workability without increasing the water content. What do you think happens if we don't use them?

The concrete would be too thick to work with?

Right, Student_3! It could lead to issues with placing and compacting. Remember the acronym 'FAST'—Flexibility, Admixtures, Strength, Timing.

What’s the role of retarders?

Retarders are crucial for controlling setting time, allowing us to work with the mix longer, which is particularly useful in hot weather.

Water Quality in HPC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

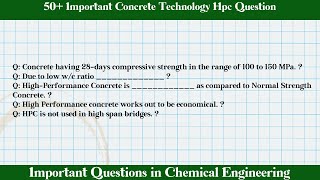

Finally, let’s discuss the quality of water used in HPC. Why is it important that the water be potable?

Because impurities could weaken the concrete?

Exactly! Any harmful salts or organic impurities can significantly decrease concrete performance. The ideal water-cement ratio is low, typically between 0.25 and 0.35!

Can we use cloudy water?

No, using cloudy or contaminated water can jeopardize strength and durability. Always remember, 'Pure Water, Pure Concrete'!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

High Performance Concrete (HPC) utilizes various materials to achieve its specialized characteristics. This section details the use of different types of cement, such as Ordinary Portland Cement and blended cements, the importance of supplementary cementitious materials like silica fume and fly ash, the quality and grading of aggregates, types of chemical admixtures, and the necessity of using potable water.

Detailed

Detailed Summary

High Performance Concrete (HPC) demands specific materials that enhance its superior characteristics. The essential components include:

- Cement: Both Ordinary Portland Cement (OPC) and blended cements like Portland Pozzolana Cement (PPC) are used. Compatibility with admixtures is essential for performance.

- Supplementary Cementitious Materials (SCMs): Materials such as silica fume (5–10% replacement) enhance strength and durability; fly ash improves workability and long-term strength; Ground Granulated Blast Furnace Slag (GGBS) enhances durability while reducing heat of hydration, and other materials like metakaolin can target specific performance properties.

- Aggregates: High-quality, well-graded aggregates with low water absorption are crucial. The typical maximum aggregate size is between 10-20 mm.

- Chemical Admixtures: These include superplasticizers for workability, retarders, accelerators, and viscosity-modifying agents to ensure optimal performance and stability.

- Water: Water must be potable and free of harmful substances, with low water-cement ratios (0.25–0.35) to guarantee low permeability and high strength.

The careful selection and optimization of materials play a vital role in achieving the desired performance in HPC structures.

Youtube Videos

![High Performance Concrete [HPC]- 1/CT M5 V9](https://img.youtube.com/vi/pZC0AdxUf6Q/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Cement Types for HPC

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Cement

• Use of Ordinary Portland Cement (OPC) Grade 43 or 53.

• Blended cements like Portland Pozzolana Cement (PPC) or Portland Slag Cement (PSC) are also used for durability.

• Compatibility with admixtures is crucial.

Detailed Explanation

In High-Performance Concrete (HPC), the choice of cement is crucial to achieve desired properties. Ordinary Portland Cement (OPC) is commonly used, specifically grades 43 and 53, due to their significant strength. Additionally, blended cements like Portland Pozzolana Cement (PPC) or Portland Slag Cement (PSC) are incorporated to enhance durability against environmental factors. It's also essential that the cement used is compatible with any chemical admixtures, which play a role in improving the concrete's performance.

Examples & Analogies

Think of selecting cement like choosing the right ingredient for a recipe. Just as the right flour affects the quality of bread, the right type of cement ensures the concrete can withstand stresses and adverse conditions.

Supplementary Cementitious Materials (SCMs)

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Supplementary Cementitious Materials (SCMs)

• Silica Fume: Enhances strength and durability, used in 5–10% replacement.

• Fly Ash: Improves workability and long-term strength.

• Ground Granulated Blast Furnace Slag (GGBS): Enhances durability and reduces heat of hydration.

• Metakaolin, Rice Husk Ash, and Alccofine are also used for specific performance targets.

Detailed Explanation

Supplementary Cementitious Materials (SCMs) are materials added to concrete to replace a portion of the cement, offering benefits such as improved strength, durability, and workability. For example, Silica Fume is known for significantly enhancing the durability and strength of concrete when used in small percentages (5-10%). Fly Ash helps with long-term strength and workability, while GGBS contributes to reduced heat generation during hydration and overall durability. Other SCMs like Metakaolin and Rice Husk Ash are used for achieving specific performance characteristics.

Examples & Analogies

Adding SCMs to concrete is like adding spices to a dish – they enhance overall quality and provide unique flavors that improve the final outcome of your recipe.

Quality of Aggregates

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Aggregates

• High-quality, well-graded coarse and fine aggregates.

• Low water absorption and minimal deleterious materials.

• Maximum aggregate size typically 10–20 mm for HPC.

Detailed Explanation

The quality of aggregates used in HPC is a significant factor influencing its performance. It is essential to use high-quality, well-graded coarse and fine aggregates, which help in achieving optimal packing and minimizing voids. Aggregates must also have low water absorption and should not contain harmful materials that could weaken the concrete. Typically, the maximum size of the aggregates used in HPC is between 10 and 20 mm, providing an ideal balance between workability and strength.

Examples & Analogies

Choosing the right aggregates is like selecting the right building blocks for a sturdy structure. Just as the foundation of a house relies on high-quality bricks or blocks, HPC depends on quality aggregates for structural integrity.

Chemical Admixtures in HPC

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Chemical Admixtures

• Superplasticizers (High Range Water Reducers): Essential for achieving high workability without increasing water content.

• Retarders: To control setting time.

• Accelerators: For early strength.

• Viscosity Modifying Agents (VMAs): For pumpability and stability in SCC (Self-Compacting Concrete).

Detailed Explanation

Chemical admixtures play a vital role in enhancing the performance characteristics of HPC. Superplasticizers are used to increase the workability of the concrete mix without adding more water, which is crucial for maintaining low water-cement ratios. Retarders are employed to slow down the setting time, making it easier to work with the concrete during hot weather. Accelerators speed up the setting process, ensuring quick strength gain, while Viscosity Modifying Agents (VMAs) improve the stability and flow of Self-Compacting Concrete, making it easier to pump and place.

Examples & Analogies

Think of chemical admixtures like tools in a toolbox. Each tool has a specific purpose, whether it’s speeding up a process or improving the quality of the work. By carefully selecting and using them, you can achieve the best results in your concrete projects.

Water Quality and Usage

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Water

• Potable quality water with no harmful salts or organic impurities.

• Water-cement ratio as low as 0.25–0.35.

Detailed Explanation

The quality of water used in preparing HPC is crucial to ensure the integrity and durability of the concrete. Potable water, free from harmful salts and organic substances, is essential to avoid adverse chemical reactions that could compromise strength. Additionally, maintaining a low water-cement ratio of 0.25 to 0.35 is critical for achieving high strength and low permeability, which helps protect against environmental damage.

Examples & Analogies

Imagine baking a cake; using clean, good quality water is like using fresh ingredients. Just as spoiled ingredients can ruin the cake, poor quality water can adversely affect the concrete, leading to a structurally unsound product.

Key Concepts

-

Cement: Fundamental ingredient to bind aggregates and provides the required strength.

-

Supplementary Cementitious Materials (SCMs): Enhance performance characteristics such as strength and durability.

-

Chemical Admixtures: Improve workability and control setting times of the concrete mix.

-

Aggregates: The main component that affects the weight and volume, influencing concrete's physical properties.

-

Water-Cement Ratio: Critical for achieving the desired strength and ensuring durability.

Examples & Applications

Using silica fume in the concrete mix can enhance durability and resist environmental aggressors.

Blended cements can be utilized in severely corrosive environments such as marine structures.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cement binds, with additives it aligns, keep it pure, just like fine wines.

Stories

Imagine a concrete wizard mixing potions with magic materials; the potion is strong and impervious to weather, thanks to the SCMs and careful aggregates.

Memory Tools

Remember 'C.A.W.S.' for concrete: Cement, Aggregates, Water, and Superplasticizers as key components!

Acronyms

Use the acronym 'DAMP' for the benefits of aggregates

Density

Absorption

Mixing

Performance.

Flash Cards

Glossary

- Ordinary Portland Cement (OPC)

A common type of cement used in concrete manufacturing with varying grades based on strength.

- Supplementary Cementitious Materials (SCMs)

Materials added to concrete mixes to enhance performance, such as silica fume, fly ash, and GGBS.

- Superplasticizers

Chemical admixtures that greatly increase the fluidity of concrete mixes without adding additional water.

- Aggregates

Inert particles, such as sand and gravel, that constitute the bulk of concrete.

- WaterCement Ratio

The ratio of the mass of water to the mass of cement used in a concrete mix.

Reference links

Supplementary resources to enhance your learning experience.