Principles of Mixture Proportioning for HPC

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Target Performance Specification

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss the importance of target performance specifications in HPC mixture design. Can anyone tell me what we mean by 'target performance'?

Is it the desired strength and durability of the concrete?

Exactly! When we set performance targets, we define the required strength, slump, setting time, and durability to ensure that the concrete meets the project's needs. Let’s remember this as the 'SDSD' acronym—Strength, Durability, Slump, and Design!

So, a high slump means it’s more workable, right?

Precisely! But there's a balance—it must also meet strength requirements. Would anyone like to add a thought?

How do we ensure the concrete is durable enough?

We achieve durability through careful material selection and proportioning. Let’s summarize that target specifications guide our expectations for concrete performance.

Selection of Appropriate Materials

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we’ll discuss selecting appropriate materials. Why do you think this step is essential?

If we don’t choose the right materials, the concrete won’t achieve the desired performance.

Absolutely! It's important to select compatible cements, SCMs, aggregates, and admixtures. Can anyone name an SCM and its benefit?

Silica fume helps increase strength.

Great! And remember, choosing materials that work well together is like creating a team where everyone contributes their strengths effectively.

So, it’s not just about using the strongest materials?

That's correct! Performance-based design requires the right combination for the expected outcomes. Let's recap: proper material selection is crucial for achieving HPC's desired properties.

Water-Binder Ratio

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's explore the water-binder ratio. What does this ratio influence in our concrete mixture?

Doesn’t it affect both the strength and permeability of the concrete?

Correct! A lower w/b ratio, typically between 0.25 to 0.35, contributes to strength and minimizes permeability. Remember: 'less is more' when it comes to water here!

But how do we maintain workability with a low ratio?

Good question! We can use superplasticizers to enhance workability without adding too much water. Summarizing, the water-binder ratio is a powerful tool in HPC design.

Trial Mixes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s talk about trial mixes. Why do you think they are vital in the design process?

To test if the mixture actually meets our specifications, right?

Exactly! Trial mixes allow us to experiment and validate the design before full-scale production. They help us adjust factors like slump and strength in real conditions.

What do we look for in these tests?

We check the slump, strength, air content, and other durability indicators. In summary, trial mixes are a bridge from theory to practice, ensuring our HPC performs as desired.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section details the essential principles for proportioning mixtures of High Performance Concrete (HPC), which include defining target performance specifications, carefully selecting materials, optimizing particle packing, managing water-binder ratios, and employing trial mixes. Each principle is vital to achieving the desired durability and strength in concrete used for high-performance applications.

Detailed

Principles of Mixture Proportioning for HPC

Designing High Performance Concrete (HPC) involves a performance-based approach that can significantly affect the strength, durability, and overall quality of concrete. The major principles are:

- Target Performance Specification: Clearly define the required properties in fresh (workability, setting time) and hardened (strength, durability) states.

- Selection of Appropriate Materials: Combining compatible materials such as cement, Supplementary Cementitious Materials (SCMs), aggregates, and admixtures is crucial for achieving optimal performance.

- Optimization of Particle Packing: Using fine materials to fill voids between larger particles ensures better density and reduces porosity, enhancing strength and durability.

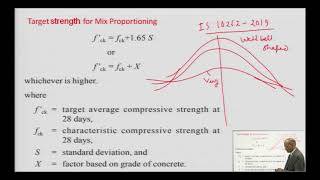

- Water-Binder Ratio: A lower water-binder ratio (w/b) typically between 0.25 and 0.35 ensures low permeability and high strength while balancing workability.

- Aggregate Grading: Continuous grading minimizes void spaces, maximizes density, and avoids segregation caused by gap grading.

- Use of Admixtures: Incorporating superplasticizers and Viscosity Modifying Agents (VMAs) help manage water demand and improve stability against segregation.

- Trial Mixes: Conducting trial mixes is essential for validating the design in actual conditions, allowing for adjustments based on setting time, slump, and strength.

Overall, these principles guide the mixing process, facilitating the creation of concrete suitable for structures requiring enhanced performance.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Target Performance Specification

Chapter 1 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Define the properties required in fresh and hardened states: strength, slump, setting time, durability, etc.

Detailed Explanation

In this step, the specific performance characteristics of the High Performance Concrete (HPC) are outlined. This means that before creating the concrete mix, engineers and designers need to determine what properties are critical for their project. For example, they must decide how strong the concrete needs to be (measured as strength), how much it can flow (measured as slump), how quickly it needs to set, and how durable it needs to be concerning environmental factors.

Examples & Analogies

Think of it as planning a recipe. If you're baking a cake, you need to define how sweet, fluffy, or moist you want the cake to be. Similarly, in concrete design, just like picking the right ingredients to get your cake to rise properly, you need to specify the right properties to get the concrete to perform as expected.

Selection of Appropriate Materials

Chapter 2 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Choose compatible combinations of cement, SCMs, aggregates, and admixtures.

Detailed Explanation

This principle highlights the importance of selecting the right materials for the concrete mix. The various materials include cement, supplementary cementitious materials (SCMs) like fly ash or silica fume, aggregates (both fine and coarse), and admixtures (like superplasticizers). Choosing materials that work well together is crucial to achieving the desired performance of the HPC.

Examples & Analogies

Consider it like choosing the right ingredients for making a smoothie. If you want a smooth, tasty drink, you wouldn't just throw any fruit together. You'd pick fruits that complement each other, ensuring they blend well. In the same way, the materials used in HPC must be compatible to achieve a smooth, strong concrete mix.

Optimization of Particle Packing

Chapter 3 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Use of fine materials (silica fume, fly ash, etc.) to fill voids between cement grains. Improves density and reduces porosity.

Detailed Explanation

Optimizing particle packing involves using fine materials to fill the gaps between larger particles in the concrete mix. This is important because denser concrete will have fewer voids, thereby reducing permeability and enhancing durability. For instance, adding materials such as silica fume helps in increasing the overall density of the concrete.

Examples & Analogies

Imagine filling a suitcase. If you only pack large items, there will be a lot of empty space left. But if you fill those gaps with smaller items, you can fit more into the same space. Similarly, in concrete, using fine materials helps to fill the gaps, making the concrete mix denser and stronger.

Water-Binder Ratio

Chapter 4 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Lower w/b ratio (typically 0.25–0.35) ensures low permeability and high strength. Must be balanced with the workability requirements.

Detailed Explanation

The water-binder (w/b) ratio is crucial in determining the strength and durability of concrete. A lower w/b ratio generally results in stronger concrete because less water means less porosity. However, it’s essential to maintain a balance where the concrete remains workable enough to be easily placed and formed during construction.

Examples & Analogies

Think about making a thick dough for cookies. If you add too much liquid, the dough becomes too runny and difficult to work with. Conversely, if you add too little, it may become so stiff that you can't shape it. Finding the right balance is key to working with concrete as well.

Aggregate Grading

Chapter 5 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Continuous grading to ensure minimum voids and maximum density. Avoid gap grading to prevent segregation.

Detailed Explanation

This principle emphasizes the importance of selecting aggregates with a continuous grading. Continuous grading means that the sizes of the aggregates used smoothly transition from small to large. This helps reduce voids within the mix, leading to a denser and stronger concrete. Avoiding gap grading is important because it can cause segregation, where larger particles separate from smaller ones.

Examples & Analogies

Consider a pile of marbles sorted by size. If you have only small and large marbles, they may not pack well together—we must instead have a variety of sizes for a tight fit. In concrete, the right mix of aggregate sizes ensures a tighter, stronger structure.

Use of Admixtures

Chapter 6 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Superplasticizers are used to reduce water demand without affecting workability. VMAs may be used where segregation is an issue.

Detailed Explanation

Admixtures are substances added to the concrete mix to enhance its performance. Superplasticizers, for example, allow for a reduction in the amount of water needed while still maintaining good workability, which is particularly important for HPC. Additionally, viscosity modifying agents (VMAs) can help to prevent segregation of the concrete mix, ensuring even distribution of materials.

Examples & Analogies

Think of superplasticizers as a natural sweetener for a healthy juice. You get the desired taste without adding extra sugar (water), maintaining both flavor and nutrition. In concrete, superplasticizers help decrease the need for more water while keeping the mixture easy to work with.

Trial Mixes

Chapter 7 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Essential for validating lab designs under real conditions. Adjustment based on setting time, slump, strength, and durability indicators.

Detailed Explanation

Trial mixes are practical tests that ensure the theoretical mix design works properly in real-world conditions. By creating several test batches, designers can adjust the proportions of the ingredients based on observed performance indicators such as how long it takes to set, how workable it feels, and its strength and durability after curing.

Examples & Analogies

It's like a chef during a recipe test. Before serving a new dish at a restaurant, the chef will make several versions, tasting them to see if the flavors balance out and adjusting ingredients as necessary. Trial mixes in concrete design serve a similar function to ensure the final product meets the necessary specifications.

Key Concepts

-

Target Performance Specification: Refers to specific requirements that the concrete must fulfill in terms of strength, workability, and durability.

-

Water-Binder Ratio: A crucial factor that affects the overall performance characteristics of the concrete.

-

Supplementary Cementitious Materials: Additives that enhance the properties of concrete mixes.

-

Trial Mixes: Initial testing of concrete mixes to assess whether they meet performance criteria.

Examples & Applications

When designing concrete for a bridge, engineers specify a compressive strength of 60 MPa and a slump of 150 mm to ensure durability and workability.

For a high-rise building, using a water-binder ratio of 0.30 with silica fume improves early strength gain and reduces permeability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For concrete strong, let’s not go wrong, measure the mix and get along!

Stories

Imagine a race between several concrete mixes, each trying to achieve superior performance. The mix that carefully chooses its materials, measures water wisely, and tests several trial mixes comes out as the winner, showing it can withstand the test of durability!

Memory Tools

Remember 'SDSD': Strength, Durability, Slump, and Design within target performance.

Acronyms

WPM

Water

Particle packing

Material selection—key concepts to remember.

Flash Cards

Glossary

- High Performance Concrete (HPC)

Concrete designed to have superior properties such as high strength, durability, and resistance to environmental aggressors.

- WaterBinder Ratio

The ratio of the amount of water to the amount of cementing materials in a concrete mixture, crucial for determining strength and permeability.

- Target Performance Specification

Defined properties that concrete must meet in fresh and hardened states, including strength and workability.

- Supplementary Cementitious Materials (SCMs)

Materials added to cement to enhance concrete performance, such as silica fume and fly ash.

- Trial Mixes

Initial test batches of concrete used to validate mix designs under real conditions before full-scale production.

- Particle Packing

The arrangement of particles in a mixture that affects its density and porosity.

Reference links

Supplementary resources to enhance your learning experience.