AI and Machine Learning in Mix Design

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to AI in Mix Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore how artificial intelligence is revolutionizing the mix design for high-performance concrete. AI can analyze complex data sets to predict the best material proportions for our concrete mixes.

So, what exactly does AI do to help us with that?

Great question! AI uses algorithms that can learn patterns from historical data, which allows engineers to determine optimal proportions without running numerous physical tests.

Does this make the process faster and cheaper?

Exactly! It reduces the time and cost involved in traditional trial-and-error methods in mix design.

Are there any specific software tools that use AI for this?

Yes, there are numerous tools available in the market that engineers use to leverage AI for predictive mix design. We'll touch on those shortly.

Machine Learning Algorithms

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's look at specific machine learning algorithms that are most commonly used in mix design.

What are some examples of these algorithms?

Common algorithms include regression analysis, decision trees, and neural networks. Each has its advantages depending on the complexity of the data.

How do these algorithms learn?

They analyze input data—like material properties and previous mix outcomes—to adjust their parameters through processes like training. The goal is to improve prediction accuracy over time.

So does that mean over time AI gets better at predicting the right mix?

Exactly! The more data they process, the more accurate their predictions become. This leads to more effective and tailored mix designs.

Cost-Effectiveness and Sustainability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

One significant benefit of AI in mix design is its capacity to help create more sustainable concrete mixes.

In what way does it do that?

By recommending the optimal use of supplementary cementitious materials which can help lower carbon emissions. This also contributes to cost savings.

Can you give an example of a material that might be recommended?

Certainly! Materials like fly ash and slag can effectively replace a portion of cement and enhance durability while reducing the environmental impact.

So AI can help in achieving our sustainability goals?

Absolutely! Successfully implementing AI-driven design not only enhances the performance of concrete but aligns with modern sustainability initiatives.

Real-World Applications and Challenges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's shift focus to real-world applications of these AI technologies in mix design and some challenges.

What are some challenges we might face?

Challenges include the need for high-quality data and the understanding of complex algorithms. If the data is poor, the predictions won't be reliable.

And what about in practice? Have companies started using AI?

Yes, many leading firms are already using AI-driven software for mix design, and the results have been promising in terms of cost-saving and improving concrete quality.

So there’s a significant future for AI in the concrete industry?

Definitely! As technology advances, we can expect further innovations that will make mix design more efficient and effective.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The integration of AI and machine learning in mix design allows for predictive modeling of optimal material proportions, enhancing cost-effectiveness and performance efficiency in high-performance concrete mixes. These innovations minimize reliance on traditional trial-and-error methods.

Detailed

In this section, we delve into how artificial intelligence (AI) and machine learning (ML) are transforming the design of high-performance concrete (HPC) mixtures by predicting optimal mix proportions. Traditional mix design typically involves extensive trial mixes to identify the best combination of materials and their proportions, which can be time-consuming and costly. AI and ML algorithms can analyze vast datasets generated from previous mix trials, enabling them to identify patterns and correlations that might not be readily apparent to engineers. By applying these advanced computational techniques, practitioners can refine their mix designs, minimize the number of trial mixes needed, and ensure that the resulting concrete not only meets the required performance specifications but also adheres to budgetary constraints. Additionally, the application of AI in this context is instrumental in enhancing sustainability by recommending the most effective use of supplementary cementitious materials, thereby reducing the carbon footprint associated with concrete production.

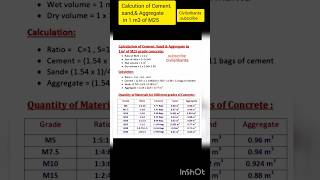

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to AI and Machine Learning in Mix Design

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Machine learning models predict optimal mix proportions.

Detailed Explanation

AI and machine learning are modern technologies that can analyze vast amounts of data quickly and efficiently. In the context of concrete mix design, these technologies are applied to predict the best combinations of materials needed to create a concrete mix with specific performance characteristics. This involves using algorithms that learn from previous mix designs and their respective performances to suggest the optimal proportions for new mixtures.

Examples & Analogies

Think of it like a recipe for baking a cake. If you learn from multiple experiments with different ingredients, you can adjust the proportions to achieve the ideal taste and texture. Similarly, AI analyzes past mix designs to recommend the best ratios of sand, cement, and water for optimal concrete performance.

Cost-Effectiveness through Algorithms

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Algorithms reduce trial mixes and improve cost-effectiveness.

Detailed Explanation

Traditionally, finding the perfect concrete mix involves a lot of trial and error, which can be costly and time-consuming. However, by using machine learning algorithms, the number of required trials can be significantly reduced. The algorithms can predict successful mix designs based on the input data, leading to savings in both materials and labor, as fewer test mixes need to be conducted.

Examples & Analogies

Imagine you're trying to find the best route for your daily commute. Instead of driving the same route multiple times to see which is fastest, you could use a navigation app that learns from traffic patterns and suggests the best route. Similarly, AI in mix design helps find the best concrete mix without many experimental trials.

Key Concepts

-

AI (Artificial Intelligence): Technology driving analysis and predictions in concrete mix design.

-

Machine Learning (ML): Algorithms that allow systems to learn from data patterns.

-

Predictive Modeling: The act of forecasting the optimal mix design using historical data.

-

Supplementary Cementitious Materials: Materials that assist in improving the properties and sustainability of concrete.

Examples & Applications

Integration of AI in predicting the best mix proportions for high-performance concrete.

Real-time data analysis from past projects to tailor future mix designs.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Mix it right with AI's might, concrete strong and clean, a sight!

Stories

Imagine a concrete engineer using an ancient tome filled with formulas. One day, AI whispers in their ear, suggesting a precise mix after analyzing countless experiments, leading to a perfect batch of concrete!

Memory Tools

Remember: 'DATA' - Design with AI for Top Analysis! Always utilize AI for effective predictions.

Acronyms

PREDICT - Predictive Research Enhances Design in Concrete Technologies.

Flash Cards

Glossary

- Artificial Intelligence (AI)

The simulation of human intelligence processes by machines, especially computer systems, used for learning and decision-making.

- Machine Learning (ML)

A subset of AI focused on the development of algorithms that allow computers to learn from and make predictions based on data.

- Predictive Modeling

Using statistical techniques to predict outcomes based on historical data and analysis.

- Trial Mixes

Experimental batches of concrete made to test various compositions and performance characteristics.

- Supplementary Cementitious Materials (SCMs)

Materials other than Portland cement used in concrete, such as fly ash, silica fume, and slag, to enhance properties and sustainability.

- Data Analysis

The process of inspecting, cleansing, transforming, and modeling data to discover useful information, informing conclusions and decisions.

Reference links

Supplementary resources to enhance your learning experience.