Criteria for Selection of Bituminous Binders

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Climatic Conditions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start by exploring how climatic conditions influence the choice of bituminous binders. Can anyone tell me why the climate may affect our choice?

I guess it's because some binders may perform better in warmer or colder areas?

Exactly! In hot climates, we typically use high-viscosity grades to withstand the heat, whereas in colder climates, softer grades are preferred to prevent cracking. Remember: 'Hot needs hard, cold needs soft.'

So, we have to consider temperature fluctuations when selecting?

Correct! The binder must remain flexible in cold weather to handle low temperatures without cracking. That's a key point to remember.

What happens if we use the wrong binder?

Good question! Using the wrong binder can lead to road failure, leading to costly repairs. In summary, always consider the climate!

Traffic Volume and Type

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss traffic volume and type. How do you think these factors influence our binder choice?

Maybe heavier traffic needs stronger binders?

Yes! For heavy or high-speed traffic, we use modified binders like PMB and CRMB to enhance performance under stress. Say it with me: 'Heavy traffic needs the sturdy!'

And lighter traffic can use regular binders?

Exactly! It's essential to match the binder's characteristics to the expected traffic load. If we overlook this, the pavement could wear down quickly.

Layer Type

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s look at layer type. What role does this play in binder selection?

Do different layers need different binders?

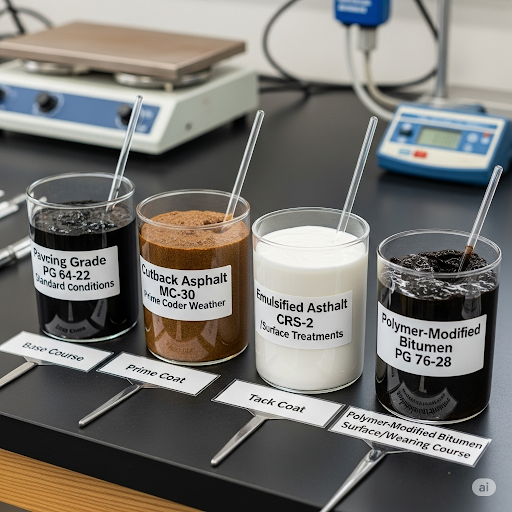

You got it! For example, emulsions are commonly used for tack coats and prime coats, while viscosity-graded bitumen is tailored for base and surface layers. Remember the layering principle!

So, if I’m working on a surface layer, I wouldn’t use an emulsion?

Precisely! Each layer has its needs based on construction and traffic requirements.

Construction Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s address construction techniques. How might they impact our binder choices?

Some techniques might require specific types of binders, right?

Exactly! For instance, emulsions are ideal for cold applications, while cutbacks are preferred in limited access areas because they can be applied at lower temperatures. Remember: 'Cold calls for emulsions!'

So, it's not just about the binder itself, but how we apply it!

Correct! Practical application is critical. Always think about the method when selecting a binder.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The selection of bituminous binders is critical for ensuring optimal performance in road construction. Key criteria include the climatic conditions of the area, the volume and type of traffic the road will bear, the type of pavement layer being constructed, and the methods of construction being employed.

Detailed

In the selection of bituminous binders for pavement construction, engineers must consider various critical factors to ensure performance and longevity. Climatic conditions play a pivotal role, where high-viscosity grades are preferred in hotter regions and softer grades in colder areas. The volume and type of traffic also significantly influence binder choice; modified binders like Polymer Modified Bitumen (PMB) and Crumb Rubber Modified Bitumen (CRMB) are recommended for heavy and high-speed traffic to enhance durability and performance. The type of pavement layer is another critical aspect, with bituminous emulsions typically used for tack coats and prime coats, while viscosity-graded bitumen is favored for base and surface layers. Lastly, construction techniques determine the choice as emulsions may be employed for cold applications, and cutbacks are often selected for limited access areas. Overall, understanding these criteria is essential for achieving cost-effective and lasting road performance.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Influence of Climatic Conditions

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Climatic Conditions: High-viscosity grades in hot regions; softer grades in cold regions.

Detailed Explanation

The selection of bituminous binders is heavily influenced by the climate of the area where they will be used. In regions with hot climates, binders with high viscosity are preferable. This is because high-viscosity bitumen can withstand high temperatures without becoming too soft or losing its structural integrity. Conversely, in colder regions, softer grades of bitumen are needed, as they maintain flexibility and prevent cracking when temperatures drop.

Examples & Analogies

Think of selecting shoes for different weather. In summer, you would prefer sturdy sandals that are durable in the heat, while in winter, you’d choose soft, warm boots that provide comfort and flexibility in cold temperatures.

Traffic Volume and Type

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Traffic Volume and Type: Modified binders (PMB, CRMB) for heavy and high-speed traffic.

Detailed Explanation

The amount and type of traffic that a road will experience directly affect the choice of bituminous binder. For roads that face heavy traffic or high-speed vehicles, modified binders such as Polymer Modified Bitumen (PMB) or Crumb Rubber Modified Bitumen (CRMB) are ideal. These binders offer improved elasticity and better resistance to deformation and cracking under heavy loads and dynamic conditions.

Examples & Analogies

Imagine putting together a puzzle that sees a lot of handling. Using a durable frame for high-traffic areas ensures the pieces stay together better, just as modified binders hold up under heavy loads on the road.

Layer Type

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Layer Type: Emulsions for tack/prime coat; viscosity-graded bitumen for base and surface layers.

Detailed Explanation

Different types of layers in road construction require different types of binders. For the tack or prime coats, bituminous emulsions are commonly used as they can easily bond layers together. On the other hand, base and surface layers are generally constructed using viscosity-graded bitumen to ensure structural soundness and durability in the long-term performance of the pavement.

Examples & Analogies

Think of layer types like the ingredients in a cake. You need specific ingredients for the base (like flour for structure) and others for the icing (like sugar for sweetness). Similarly, each road layer needs the right binder to perform its function effectively.

Construction Techniques

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Construction Techniques: Use of emulsions for cold applications; cut-backs for limited access areas.

Detailed Explanation

The methods used in constructing a road can also dictate the choice of binder. Emulsions are particularly beneficial for cold applications because they can be applied at lower temperatures, making them suitable for a variety of weather conditions. Cut-back bitumen, on the other hand, is often utilized in areas that have limited access, allowing for easier application in less ideal situations where other types of binders may not be feasible.

Examples & Analogies

If you're cooking a meal, using a microwave (which is like emulsions for slower cooking) is great for quick reheating, while using a traditional oven (akin to cut-backs) might be best for baking a pie in a kitchen with limited space. Each tool or method serves its purpose based on the situation.

Key Concepts

-

Climatic Conditions: The surrounding environment significantly affects binder selection; soft grades for cold, hard for hot.

-

Traffic Volume: Binders must accommodate the volume and type of traffic expected to ensure durability.

-

Layer Type: The type of road layer dictates binder choice; emulsions for overlays, viscosity-graded for base.

-

Construction Technique: The method of application influences binder selection; cutbacks for low-temp applications.

Examples & Applications

In a hot region, a high-viscosity binder may be selected for its ability to resist heat-induced softening.

For a lower traffic volume area, conventional bitumen may suffice, preventing excessive costs associated with modified binders.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For road construction, don't forget the type, choose right for the weather, or you'll face the hype!

Stories

Imagine a road that faced harsh sun and rain, the binders used determined joy, or pain. Choose wisely, and they’ll hold tight, or roads will crumble in plain sight.

Memory Tools

Remember 'CLT-C' for Criteria: Climatic, Layer type, Traffic, and Construction methods.

Acronyms

Use the acronym 'C-L-T-C' for selecting the right binders with Climate, Load, Type of layer, and Construction.

Flash Cards

Glossary

- Bituminous Binder

A binding agent used in road construction to hold aggregates together and provide waterproofing.

- Viscosity Grade

A classification of bitumen based on its viscosity at specific temperatures.

- Polymer Modified Bitumen (PMB)

Bitumen modified with polymers to enhance its properties, such as elasticity and fatigue resistance.

- Traffic Volume

The amount of traffic expected on a roadway, influencing binder selection.

- Emulsion

A mixture of water and bitumen where bitumen droplets are dispersed in the water phase.

Reference links

Supplementary resources to enhance your learning experience.