Setting Time Classification

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Bituminous Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss bituminous emulsions and why understanding their setting time is important. Can anyone tell me what a bituminous emulsion is?

Isn't it a mixture of bitumen and water?

Exactly! Bituminous emulsions are a dispersion of bitumen in water, stabilized by emulsifying agents. Now, how do you think the setting time classifications play a role in construction?

I think it would determine how quickly we can work with it after applying.

Correct! The setting time determines how quickly an emulsion hardens and can affect adhesion and performance.

Let's see how we categorize the emulsions. We have Rapid Setting, Medium Setting, and Slow Setting. Remember the acronym 'RMS' to help you recall these categories!

Rapid Setting Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive into Rapid Setting emulsions first. Why do you think they are given their name?

Because they set quickly, right?

Exactly! They are often used for applications requiring fast curing like tack coats. So, can anyone think of a situation where using RS would be beneficial?

It would be great for patching roads! We need to move traffic quickly after repairs.

Great example! Rapid Setting emulsions are ideal for that purpose. They allow quick reopening of roads while maintaining good adhesion.

Medium Setting Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, what about Medium Setting emulsions? How do they differ from Rapid Setting?

They take a bit longer to set, right? Maybe they're for more general use?

Exactly! They offer flexibility for multiple applications including prime coats and can be adjusted for various environmental conditions. Remember, we refer to them as MS!

What if weather conditions aren’t great? Can MS still work?

Yes, MS emulsions can handle a range of conditions, providing a good setting time for different scenarios.

Slow Setting Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's talk about Slow Setting emulsions. What might be the advantages of using SS?

Maybe they allow more time for spreading and leveling before they harden?

Precisely! SS emulsions are helpful in applications like surface dressing. Remember, slow does not mean ineffective; it provides time to manipulate the emulsion.

What about their environment? Can they be used in any weather?

Good question! While they can work well in cooler temperatures, ensuring the right conditions is always important for optimal performance.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Setting time classification of bituminous emulsions is essential for determining appropriate applications. There are three categories: Rapid Setting (RS), Medium Setting (MS), and Slow Setting (SS), each suited to different uses in road construction.

Detailed

Setting Time Classification

Setting time classification of bituminous emulsions refers to how quickly they set or cure after application, which is crucial in various road construction methods. Emulsions are categorized into three types:

- Rapid Setting (RS): This type sets quickly and is typically used in situations that require quick bonding such as tack coats.

- Medium Setting (MS): This emulsion offers a balance between rapid setting and slow setting, making it versatile for various applications.

- Slow Setting (SS): Used in applications requiring longer working times, such as surface dressing where there is a need for greater manipulation of the material before it sets.

Understanding the setting times helps in selecting the right emulsion for specific applications, thus ensuring better adhesion and performance in the finished road structure.

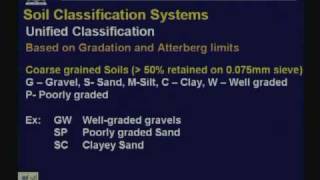

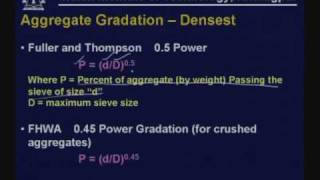

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Rapid Setting (RS)

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Rapid Setting (RS)

Detailed Explanation

Rapid Setting (RS) refers to a type of bituminous emulsion that has a fast curing time once applied. This means that after the emulsion is spread on the surface, it quickly converts from a liquid to a solid state, allowing other construction activities to resume sooner. This quality is particularly beneficial in scenarios where time is critical, such as during road repairs or when weather conditions are changing.

Examples & Analogies

Imagine you're baking a cake, and you need it to cool quickly so you can serve it at a party. Using a rapid cooling method, like placing it in the freezer, allows the cake to be ready much faster, similar to how Rapid Setting emulsions allow for quick resurfacing of roads.

Medium Setting (MS)

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Medium Setting (MS)

Detailed Explanation

Medium Setting (MS) emulsions have a moderate curing time. They are suitable when the construction schedule allows for a bit more time than what Rapid Setting provides but still requires efficient application. These emulsions fall between rapid and slow setting in terms of their time to set, providing flexibility based on project needs.

Examples & Analogies

Think of it as making a loaf of bread. If you let it rise for a while, it will rise perfectly instead of rushing it. Medium Setting emulsions allow for an optimal balance, much like letting your bread rise at just the right pace.

Slow Setting (SS)

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Slow Setting (SS)

Detailed Explanation

Slow Setting (SS) emulsions take a longer time to cure. They are used in applications where traffic can be restricted or when there is ample time for the emulsion to set properly before being subjected to loads. These emulsions are beneficial in cooler temperatures or for more complex construction scenarios where a gradual curing process is advantageous.

Examples & Analogies

Consider a slow-cooked meal, like a stew. It takes longer to prepare, but the result is richer and more flavorful. Slow Setting emulsions allow the bitumen to set more thoroughly, ensuring a strong and durable surface, much like how a well-cooked stew has better flavors.

Key Concepts

-

Bituminous Emulsions: Mixtures of bitumen and water used for road construction.

-

Rapid Setting (RS): Emulsions that set quickly for immediate use.

-

Medium Setting (MS): Emulsions that offer a balance between speed and manipulation.

-

Slow Setting (SS): Emulsions with longer working times for careful application.

Examples & Applications

Using RS emulsions for quick repairs allows for faster traffic resumption after road works.

MS emulsions are used when the setting time is flexible, suitable for prime coats on diverse surfaces.

SS emulsions are great for applications where precise leveling and spreading are critical before setting.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For rapid sets, think quick like a pet! Medium's a blend, on it you can depend, slow gives you time, so choose it in grime!

Stories

Imagine a builder planning a road. He needs quick-drying paint (RS) for fast repairs, a flexible mix (MS) for solid foundations, and a slow-drying paste (SS) for careful detailing.

Memory Tools

Remember 'RMS' for Rapid, Medium, and Slow; they guide you in your emulsion flow!

Acronyms

RMS - Rapid for fast, Medium for balance, Slow for careful application.

Flash Cards

Glossary

- Bituminous Emulsion

A mixture of bitumen and water, stabilized by emulsifying agents, used in road construction.

- Rapid Setting (RS)

Type of emulsion that sets quickly, suitable for applications like tack coats.

- Medium Setting (MS)

Emulsion that provides a balance between rapid and slow setting, used for various applications.

- Slow Setting (SS)

Emulsion with a longer setting time, allowing for extended working periods.

Reference links

Supplementary resources to enhance your learning experience.