Softening Point Test (Ring and Ball Method)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Overview of Softening Point Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about the Softening Point Test, specifically the Ring and Ball Method. Can anyone tell me what the softening point indicates about bituminous binders?

Is it about how much heat they can handle?

Exactly! The softening point tells us how temperature-sensitive a binder is, which is crucial for understanding how it will perform in different climates. Now, can anyone guess how we actually measure this?

Maybe using some sort of heating apparatus?

Right again! We heat the bitumen in a ring and drop a ball onto it to see at what temperature the ball falls. This leads us to our next discussion about the procedure of the test.

Procedure of the Ring and Ball Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive deeper into the procedure of the Ring and Ball method. First, we put a specific amount of bitumen into a brass ring. Does anyone know what happens next?

We heat it until it softens, right?

Exactly! We heat it gradually. When the softening occurs, a steel ball drops through a specific distance. This gives us the softening point. Can anyone think of why this is important?

It helps in determining the right bitumen type for paving?

Absolutely! Choosing the right binder based on this property ensures better performance of our roads under various conditions.

Importance of Softening Point in Engineering

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Why do you think knowing the softening point of the bitumen is so vital in road engineering?

Because it tells us how the roads will behave in heat!

And if it can handle heavy traffic without deforming!

Exactly! The softening point affects both the durability and safety of the pavement. Engineers use this information to select the right materials. Let's summarize today’s key points. Who can share what we learned?

We learned about the Ring and Ball Method, how it's performed, and why it’s key for binder selection!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section focuses on the Ring and Ball Method used to determine the softening point of bitumen, which is a crucial indicator of its temperature susceptibility and performance in different climate conditions. Understanding this test is essential for the effective selection and application of bituminous binders in road construction.

Detailed

Softening Point Test (Ring and Ball Method)

The Softening Point Test, particularly using the Ring and Ball method, is a crucial laboratory test for bituminous binders. This test measures the temperature at which a bitumen sample softens enough to allow a steel ball to fall through it.

Key Points:

- Purpose: The main aim of the Ring and Ball Test is to determine the softening point of bitumen, which serves as an indicator of the material's temperature susceptibility. This means how well it can handle temperature changes.

- Method: The test involves placing a bitumen sample in a ring, heating it, and then observing at which temperature a ball, resting on the bitumen, falls to a predetermined distance.

- Significance: Knowing the softening point helps engineers anticipate how a bituminous binder will perform under various environmental conditions, ensuring appropriate choices are made for different construction contexts.

This test not only quantifies a physical property of the binder but also affects decisions in construction practices. Proper binder selection based on softening points can lead to increased pavement life and performance.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Purpose of the Softening Point Test

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Measures the temperature at which bitumen softens.

• Indicates temperature susceptibility.

Detailed Explanation

The softening point test determines the temperature at which bitumen transitions from a rigid to a softer, more flowable state. This test is significant because it helps assess how well the asphalt or bitumen will perform under different temperature conditions. In road construction, understanding the softening point is crucial for ensuring that the binder can maintain its structural integrity and performance throughout varying weather conditions. This test indicates temperature susceptibility, meaning how sensitive the material’s properties are to changes in temperature.

Examples & Analogies

Imagine you have a stick of butter. When you take it out of the refrigerator, it’s hard and doesn’t spread on toast easily. As it warms up, it becomes softer and more pliable, making it easy to spread. The softening point test is similar to finding the exact temperature where the bitumen starts to lose its hardness and becomes easier to work with—like butter sitting at room temperature.

The Ring and Ball Method

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

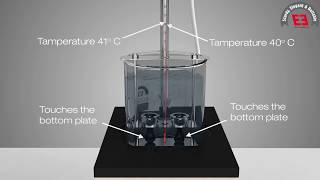

Chapter Content

The Ring and Ball Method is a specific procedure used for this test. It involves placing a sample of bitumen between two metal rings and heating it. A steel ball is then placed on top, and the setup is heated in a controlled environment. The temperature at which the ball falls a specified distance into the softened bitumen is recorded as the softening point.

Detailed Explanation

In the Ring and Ball method, the procedure begins with a sample of bitumen being prepared and sandwiched between two metal rings. This assembly is then placed on a surface, typically a heated plate. As the temperature increases slowly, the bitumen softens. The critical point is when a steel ball, which is initially resting on top of the rings, starts to descend into the bitumen. The temperature at which the ball has penetrated a certain distance into the softened bitumen is considered the softening point. This method not only provides a measurable value but also replicates real-life scenarios where temperature changes impact binder performance.

Examples & Analogies

Think of heating a gummy bear. Initially, it retains its shape and firmness, but as it warms up, it starts to melt and can no longer hold its form. The Ring and Ball method mimics this process, where we observe the exact moment the bitumen turns from solid to a more fluid form, similar to how we would watch a gummy bear soften in heat.

Key Concepts

-

Temperature Susceptibility: The ability of bitumen to change its physical state with temperature changes.

-

Softening Point Measurement: A critical property for selecting bituminous binders in road construction.

Examples & Applications

In warm climates, a bitumen with a higher softening point is preferred to prevent deformation under heat.

The Ring and Ball method provides a consistent way to assess temperature susceptibility, critical for binder performance.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When bitumen gets hot and starts to drop, its softening point is what we should stop.

Stories

Think of a warm day when the pavement feels soft, just like bitumen's journey through heat.

Memory Tools

R.B.M = Ring, Ball, Measure – a reminder of the steps in the Ring and Ball method.

Acronyms

SPT = Softening Point Test – a quick reminder of what we are learning about.

Flash Cards

Glossary

- Softening Point

The temperature at which bitumen softens sufficiently to allow a ball to penetrate a certain depth.

- Ring and Ball Method

A test method used to determine the softening point of bituminous binders by observing the temperature at which a steel ball sinks a specified distance into the sample.

Reference links

Supplementary resources to enhance your learning experience.