Handling, Storage, and Transportation of Bitumen

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Storage of Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are learning about the storage of bitumen. Can anyone tell me why it's important to store bitumen correctly?

Because it can get oxidized if overheated!

Exactly! Bitumen must be kept in well-insulated, thermostatically controlled tanks. This prevents overheating and protects against oxidation.

What happens if it oxidizes?

Great question! Oxidation can compromise the quality of the bitumen, leading to performance issues in the road construction. Remember the acronym 'S.O.S.' - Safe, Optimal Storage!

So, we need to make sure the tanks are both safe and maintained well?

Correct! Consistent temperature control is key.

To summarize: Store bitumen in insulated tanks to prevent overheating and oxidation.

Transportation of Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's talk about how we transport bitumen. Can anyone tell me what specific equipment is used for transporting it?

I think we use bitumen tankers?

That's right! Bitumen tankers are specially designed to maintain the bitumen's characteristics during transport. Why do you think compatibility is important for cutbacks and emulsions?

If they get contaminated, they wouldn't work properly?

Exactly! Contamination can lead to a compromised product, affecting road performance. Can anyone remind me what we should avoid during handling to ensure safety?

Avoid direct contact and inhalation?

Yes! Safety is critical when handling bitumen. Always use protective gear.

In summary: Use specialized tankers for transporting bitumen and ensure safety during handling by avoiding direct contact.

Safety Measures in Handling Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's now focus on safety measures. What should we do to protect ourselves when handling bitumen?

We need to wear protective gear!

That's correct! Personal protective equipment is crucial. Can someone list the types of protective gear we might need?

Maybe gloves, goggles, and masks?

Outstanding! Remember to avoid direct contact and inhalation of fumes to ensure a safe working environment. We can remember this with the acronym 'P.P.E.' - Personal Protective Equipment!

To recap, always wear protective gear and avoid contact when handling bitumen.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Bitumen must be stored in insulated tanks to prevent overheating and oxidation. Transportation should use specialized tankers, with specific care taken for emulsions and cutbacks to prevent contamination. Safety measures during handling are also emphasized.

Detailed

Handling, Storage, and Transportation of Bitumen

Storage

Bitumen should be stored in well-insulated, thermostatically controlled tanks to maintain optimal temperature and prevent overheating, thereby avoiding oxidation which can deteriorate its quality.

Transportation

Transportation of bitumen is conducted using specialized bitumen tankers tailored for preserving its characteristics. For emulsions and cutbacks, it is crucial to ensure compatibility and prevent contamination which could compromise their properties.

Safety Measures

When handling bitumen, safety precautions are vital. Direct contact and inhalation of fumes should be avoided, and protective gear should be worn to mitigate health risks.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Storage of Bitumen

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Must be stored in well-insulated, thermostatically controlled tanks.

Prevent overheating to avoid oxidation.

Detailed Explanation

Bitumen must be stored properly to maintain its properties. This requires using storage tanks that are both insulated and equipped with thermostatic controls. Insulation helps to maintain a consistent temperature inside the tanks, protecting the bitumen from external temperatures. Thermostatic controls help ensure that the bitumen does not get too hot, as excessive heat can lead to oxidation. Oxidation alters the properties of bitumen, making it less effective as a binder in road construction.

Examples & Analogies

Think of storing bitumen like keeping chocolate in a controlled environment. If you store chocolate at a stable temperature away from heat, it maintains its smooth texture. However, if it gets too hot, it can begin to melt and lose its original shape and flavor—similarly, bitumen’s qualities are compromised if overheated.

Transportation of Bitumen

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Done using bitumen tankers.

For emulsions and cutbacks, ensure compatibility and prevent contamination.

Detailed Explanation

The transportation of bitumen is a critical process that typically involves the use of specialized vehicles known as bitumen tankers. These tankers are designed to transport liquid bitumen safely. In the case of bitumen emulsions and cutbacks, it's essential to ensure that the materials are compatible with each other; otherwise, they may not function effectively when applied. Additionally, it’s crucial to prevent contamination during transportation because even small impurities can affect the performance of the bitumen.

Examples & Analogies

Imagine you're transporting a smoothie in a blender to a picnic. If you have a blender that’s specifically designed to keep the smoothie cold and prevent spillage, you can ensure that it arrives fresh. If you use a regular container that isn’t compatible with your smoothie’s ingredients, or if dirt gets in, the smoothie won't taste as good and may even make people sick. The same principle applies to transporting bitumen.

Safety Measures in Handling Bitumen

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Avoid direct contact and inhalation.

Use protective gear during handling.

Detailed Explanation

Handling bitumen requires following specific safety protocols to protect workers from potential health risks. Direct contact with bitumen can cause skin irritation and burns. Additionally, inhaling vapors from heated bitumen can lead to respiratory issues. Therefore, it is crucial to wear protective gear such as gloves, masks, and suitable clothing when handling bitumen to minimize these risks and ensure safety on-site.

Examples & Analogies

Consider how hospital staff must wear gloves and masks when working with patients to prevent infections. Just like in that scenario, wearing protective gear when working with bitumen helps safeguard against harmful substances that could cause health issues, making the work environment safer for everyone involved.

Key Concepts

-

Proper Storage: Bitumen must be stored in insulated tanks to prevent overheating and oxidation.

-

Transportation: Bitumen is transported using specialized tankers to maintain quality and prevent contamination.

-

Safety Measures: Protective gear is essential to handle bitumen safely and avoid direct contact.

Examples & Applications

An asphalt plant storing bitumen in insulated tanks can preserve its quality for extended periods.

During transport, a tanker equipped with heating systems maintains the bitumen's temperature, preventing solidification.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When you store the black goo, keep it cool, that's the rule!

Stories

Imagine a wise old tank that gets hot and fears oxidation, staying insulated to ensure it's filled with high-quality bitumen.

Memory Tools

Remember 'S.O.S.' for Safe and Optimal Storage to keep bitumen quality high!

Acronyms

P.P.E. stands for Personal Protective Equipment, vital for shipping bitumen safely.

Flash Cards

Glossary

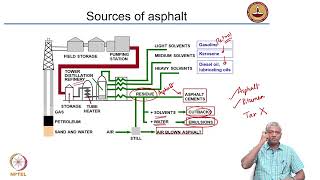

- Bitumen

A viscous, black, semi-solid material obtained as a residual product in the distillation of crude oil, used as a binder in road construction.

- Oxidation

The process where bitumen deteriorates due to exposure to heat and air, which affects its properties.

- Emulsions

Dispersions of bitumen in water stabilized by emulsifying agents, often used in road applications.

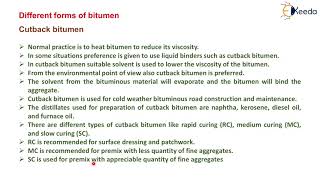

- Cutbacks

Bitumen diluted with volatile solvents to reduce viscosity, allowing for easier application at lower temperatures.

Reference links

Supplementary resources to enhance your learning experience.