Properties and Tests of Bituminous Binders

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Penetration Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let's start with the Penetration Test. This test helps us measure the hardness of bituminous binders. Can anyone tell me why it's important to know how hard or soft a binder is?

I think softer binders might be better in colder climates?

Exactly! Softer binders can provide better flexibility and resistance to cracking in cold temperatures. We use specific loads and temperatures to ensure consistent results.

What do the numbers like 60/70 mean?

Good question! It's the penetration grading, which indicates the hardness of the binder. A 60/70 grade means a penetration depth of 60 to 70 decimillimeters at a standard test condition.

To remember the key idea, think 'Soft in the cold, hard for the hot.'

So, if it's too hard, it can crack?

Yes! That's why choosing the right grade for the climate is essential. Let's summarize: the Penetration Test measures binder hardness and helps in selecting the appropriate binder for different conditions.

Ductility and Softening Point Tests

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on, let's discuss the Ductility Test. It measures how much a binder can stretch before breaking. Why might this property be vital?

Maybe for areas with high traffic?

Exactly! A flexible binder can better handle stresses from traffic and temperature changes. Next, we have the Softening Point Test. Can anyone explain what that determines?

It tells us the temperature where the bitumen starts to flow, right?

Correct! Knowing the softening point is essential for understanding how the binder behaves in heat. Let's remember, 'Ductility stretches, while heat beckons softening!'

What happens if the softening point is too low?

If it's too low, the binder may flow too much and lose its structural integrity under high temperatures. Summarizing, ductility measures flexibility, and the softening point indicates flow behavior!

Viscosity, Flash and Fire Point Tests

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's cover the Viscosity Test. Why do you think that's important for bituminous binders?

Isn't it about how thick the bitumen is?

Yes! It helps us understand how the binder will flow during mixing and application. Now, let’s discuss Flash and Fire Point Tests. Can anyone explain their significance?

They indicate how flammable the binder is, right?

Exactly! These tests are crucial for safety in storage and handling. Remember: 'Viscosity for flow and flashpoint for safety!'

What happens if we ignore these tests?

Ignoring them can lead to unsafe conditions and poor pavement performance. In summary, viscosity determines flow characteristics, while flash points ensure safety.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

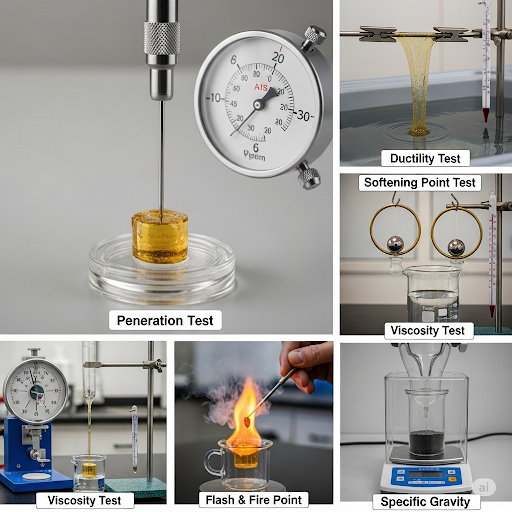

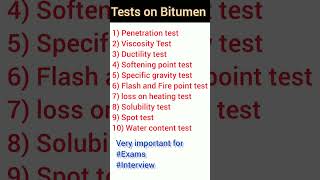

In this section, several key laboratory tests for evaluating bituminous binders are discussed, including the penetration test, ductility test, softening point test, and others, which help determine the binder's performance in various conditions. The understanding of these tests is vital for ensuring the quality and longevity of flexible pavements.

Detailed

Properties and Tests of Bituminous Binders

Bituminous binders play a critical role in road construction, especially in flexible pavements. To ensure their suitability, a series of laboratory tests are conducted to assess their properties. The section introduces several key tests:

- Penetration Test: Measures the hardness of the bitumen using a penetrometer under standardized conditions. A higher penetration value indicates a softer binder, while a lower value indicates a harder binder.

- Ductility Test: This test evaluates the ability of a bitumen sample to stretch without breaking, serving as an indicator of flexibility. It is critical in environments where temperature changes may occur.

- Softening Point Test (Ring and Ball Method): Determines the temperature at which the bitumen begins to flow, indicating its temperature susceptibility. This is essential for understanding how the binder will perform as temperatures rise or fall.

- Viscosity Test: Assesses the flow behavior of bitumen at high temperatures using viscometers such as the Saybolt Furol and Brookfield, indicating how the binder may perform during mixing and laying.

- Flash and Fire Point Tests: Important for safety, these tests indicate the temperatures above which the bitumen can ignite, ensuring safe storage and handling practices.

- Specific Gravity Test: This test determines the density of bitumen, which affects the mixing ratios and characteristics of the pavement.

These tests help ensure the selected binder meets the required performance standards for various environmental and load conditions, which is vital for the longevity and durability of road structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Penetration Test

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Penetration Test:

- Measures hardness.

- Penetrometer used under standard load, time, and temperature.

Detailed Explanation

The Penetration Test is a laboratory procedure that determines the hardness of bituminous binders. A device called a penetrometer measures how far a needle can penetrate into the binder under defined conditions, involving a specific load, time duration, and temperature. The further the needle penetrates, the softer the binder is considered to be. This test helps engineers understand how the binder will perform under load and temperature conditions during its usage.

Examples & Analogies

Think of the Penetration Test like testing the firmness of a cake; if you poke it with your finger and it leaves a deep impression, the cake is soft. But if your finger barely sinks in, the cake is firm. Similarly, a softer bitumen will allow for more penetration.

Ductility Test

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Ductility Test:

- Measures the extent a bitumen sample can stretch before breaking.

- Indicator of binder flexibility.

Detailed Explanation

The Ductility Test evaluates how flexible a bituminous binder is by measuring how much it can stretch before breaking. During the test, a sample of the binder is pulled apart, and the distance it can stretch (ductility) is measured. This test is important because it provides insight into how the binder will handle stress without cracking, which is crucial for road durability.

Examples & Analogies

You can think of this test like stretching a piece of taffy. If the taffy stretches far without snapping, it indicates that it has good ductility. This flexibility is essential to absorb stresses from traffic and temperature changes in road materials.

Softening Point Test (Ring and Ball Method)

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Softening Point Test (Ring and Ball Method):

- Measures the temperature at which bitumen softens.

- Indicates temperature susceptibility.

Detailed Explanation

The Softening Point Test identifies the temperature at which bitumen transitions from a solid to a more fluid state. Using the Ring and Ball method, a small sample of bitumen is heated in a controlled environment with a ball placed on the sample. The temperature is gradually increased until the ball sinks a certain distance into the binder. This gives engineers a clear indication of how the binder behaves at different temperatures, which is critical for ensuring that roads remain stable in various weather conditions.

Examples & Analogies

Imagine melting chocolate. When you heat chocolate, it starts to soften before it completely melts. Just as you determine the right temperature to work with chocolate, engineers use the softening point to understand the working limits of bitumen.

Viscosity Test

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Viscosity Test:

- Measures flow behavior at high temperatures.

- Done using viscometers like Saybolt Furol and Brookfield.

Detailed Explanation

The Viscosity Test assesses how easily a bituminous binder flows at elevated temperatures. This is done using specialized equipment called viscometers, such as the Saybolt Furol and Brookfield. The viscosity level is vital because it influences the application methods and performance of the binder in real-world conditions. High viscosity indicates a thicker, more resistant material, while low viscosity suggests a thinner, more fluid binder.

Examples & Analogies

You can relate viscosity to the way different liquids behave when poured. For example, pouring honey (high viscosity) takes longer than pouring water (low viscosity). The viscosity test essentially measures this characteristic in bitumen, ensuring it can flow properly during application.

Flash and Fire Point Tests

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Flash and Fire Point Tests:

- Indicates the temperature beyond which the material may ignite.

- Important for safe storage and handling.

Detailed Explanation

The Flash and Fire Point Tests help determine the safety thresholds for the storage and handling of bituminous binders. The flash point is the lowest temperature at which the vapor from the binder can ignite when exposed to a flame, while the fire point is the temperature at which the vapor continues to burn. Knowing these temperatures ensures that workers can safely transport and store the material without risk of ignition.

Examples & Analogies

Think of the Flash and Fire Point Tests like knowing the safe temperature to keep a flammable liquid. For example, just like you wouldn’t store gasoline near a heat source, these tests help ensure that bitumen is handled safely in a controlled environment.

Specific Gravity Test

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Specific Gravity Test:

- Affects aggregate-bitumen mixing and pavement density.

Detailed Explanation

The Specific Gravity Test measures the density of bituminous binders, which is essential for understanding how it will interact with aggregates in concrete mixes. A higher specific gravity indicates denser materials, which can affect the stability and load-bearing characteristics of the finished pavement. This test is crucial during the design phase to ensure that the mix yields optimal performance.

Examples & Analogies

You can think of specific gravity like weighing apples and oranges. If you know the specific weight of each type of fruit, you can figure out how many you need for a fruit salad. Similarly, knowing the specific gravity of bitumen helps engineers decide the right amounts for pavement mixes.

Key Concepts

-

Penetration Test: Measures the hardness of bituminous binders.

-

Ductility Test: Assesses flexibility by measuring the stretching capability of binders.

-

Softening Point Test: Determines the temperature at which a binder begins to flow.

-

Viscosity Test: Evaluates flow behavior at high temperatures.

-

Flash Point: The temperature at which bitumen may ignite.

-

Fire Point: The temperature at which bitumen continues to burn.

-

Specific Gravity: Impacts mixing ratios and pavement density properties.

Examples & Applications

A penetration grade of 60/70 indicates a binder suitable for moderate climates, balancing hardness and flexibility.

If a binder fails the ductility test, it may be unsuitable for areas experiencing extreme temperature fluctuations.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Penetrate to find the rate, soft to stretch, hard to rate.

Stories

Once, in a hot summer town, bitumen started to melt all around. The engineers tested its flow, to make sure the roads wouldn’t glow under the radiant sun, safety was their top run.

Memory Tools

DSSV: Ductility, Softening, Specific Gravity, Viscosity.

Acronyms

PSV

Penetration

Softening

Viscosity - key tests for pavement safety.

Flash Cards

Glossary

- Penetration Test

A test measuring the hardness of bitumen using a penetrometer.

- Ductility Test

A test measuring the ability of bitumen to stretch without breaking.

- Softening Point Test

A test determining the temperature at which bitumen starts to flow.

- Viscosity Test

A test assessing the flow behavior of bitumen at high temperatures.

- Flash Point

The temperature at which bitumen can ignite when exposed to flame.

- Fire Point

The temperature at which bitumen continues to burn after ignition.

- Specific Gravity

The density of bitumen, affecting its mixing and pavement properties.

Reference links

Supplementary resources to enhance your learning experience.