Cutback Bitumen

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Cutback Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing cutback bitumen! It’s formulated by diluting bitumen with volatile solvents. Can anyone tell me why this might be needed?

Is it to make it easier to apply at lower temperatures?

Exactly! We use cutback bitumen in cooler climates or during specific construction times to ensure proper application. Let’s remember the acronym **EASE**: **E**asy to apply, **A**llows for flexibility, **S**pecial solvents, and **E**ffective in cold conditions.

What types of solvents are used?

Great question! We typically use petrol for rapid curing, kerosene for medium curing, and diesel or heavy oils for slow curing. So just remember **P**etrol, **K**erosene, and **D**iesel for our solvents!

Types of Cutbacks

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s explore the types of cutbacks in detail. Who can identify the three types?

Rapid curing, medium curing, and slow curing?

Exactly! Remember **RC**, **MC**, and **SC**! RC is for rapid applications, MC for priming surfaces, and SC is for cold mixes. Each type has specific uses. Can anyone provide an application for RC?

Patch repairs!

Right on! And what about MC?

It’s used for prime coats?

Perfect! Now let’s recap with **Application Army** — **A**RC for repairs, **A**MC for priming.

Environmental Considerations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s talk about environmental concerns. What do we know about VOCs in cutback bitumen?

They are harmful emissions released during application.

Correct! VOCs contribute to air pollution, and that’s why cutbacks are becoming less favored. Remember the phrase, 'Don't cut back on air quality!'

Are there fewer environmental regulations for other types of bitumen?

Other types, like emulsions, tend to be more environmentally friendly. Understanding these impacts is crucial for engineers to comply with regulations and promote sustainability.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores cutback bitumen, detailing its types based on curing speed, various applications, and environmental considerations. Understanding cutback bitumen is essential for its effective use in construction and compliance with environmental regulations.

Detailed

Cutback Bitumen

Cutback bitumen refers to bitumen that is diluted using volatile solvents to reduce its viscosity, enabling easy application in lower temperature conditions. This section is subdivided into the following subsections:

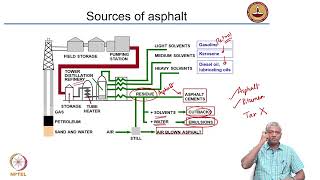

10.4.1 Types of Cutbacks

There are three main types of cutback bitumen based on the curing speed:

- Rapid Curing (RC): Uses petroleum or naphtha as solvents. Commonly used for patch repairs and surface dressing.

- Medium Curing (MC): Uses kerosene, primarily utilized for prime coats.

- Slow Curing (SC): Utilizes diesel or heavier oils, often applied in preparing cold mixes.

10.4.2 Applications

Each type serves specific functions, including:

- RC: Effectively used for quick applications like patch repairs.

- MC: Ideal for treating surfaces prior to paving with hot bitumen.

- SC: Appropriate for cold mix asphalt production, providing flexibility in construction conditions.

10.4.3 Environmental Considerations

Cutbacks, due to their volatile components, release a significant amount of volatile organic compounds (VOCs). Consequently, their popularity has diminished in many regions due to stricter environmental regulations aimed at reducing VOC emissions. Environmental awareness is essential for transportation engineers in planning and selecting appropriate materials for road construction.

Youtube Videos

![[Highway Engineering #1] Cutback Bitumen MC 30 and MC 70 | Asphalt | Bitumen | Coal Tar](https://img.youtube.com/vi/Aa4UTFt2OFM/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Cutback Bitumen

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Cutbacks are bitumen diluted with volatile solvents to reduce viscosity for ease of application at lower temperatures.

Detailed Explanation

Cutback bitumen is a type of asphalt that has been mixed with specific solvents to make it less thick and easier to apply. The process of dilution lowers the viscosity, which means the mixture flows more easily. This property is particularly useful when the temperature is lower, as standard bitumen can become too stiff to work with. By using cutback bitumen, road construction can proceed without needing to worry about the material becoming too rigid in cooler conditions.

Examples & Analogies

Think of cutback bitumen like mixing paint with thinner. When you want to apply paint on a chilly day, adding a little thinner helps it spread smoothly rather than clumping up or becoming hard to brush out.

Types of Cutbacks

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

10.4.1 Types of Cutbacks:

- Rapid Curing (RC): Uses petrol or naphtha as solvent.

- Medium Curing (MC): Uses kerosene.

- Slow Curing (SC): Uses diesel or heavy oils.

Detailed Explanation

There are three primary types of cutback bitumen, classified based on the solvent used to dilute the bitumen, and each has specific applications. Rapid Curing (RC) cutbacks evaporate quickly and are often used for quick fixes like patching. Medium Curing (MC) takes a bit longer to cure and is commonly used as a prime coat because it adheres well to surfaces. Slow Curing (SC) takes the longest to dry and is suitable for cold mix asphalt production because it retains moisture longer, allowing the mixture to remain workable.

Examples & Analogies

Consider cutbacks like different types of smoothies: a Rapid Curing is like a quick-to-drink smoothie that you make with ice (fast evaporation), Medium Curing is like a thicker smoothie that takes a little longer to enjoy (ideal for priming), and Slow Curing is similar to a meal replacement shake that stays thick and creamy for a while (great for cold applications).

Applications of Cutback Bitumen

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

10.4.2 Applications:

- RC: Patch repairs, surface dressing.

- MC: Prime coat.

- SC: Cold mix preparation.

Detailed Explanation

Each type of cutback bitumen has specific applications based on its curing time. Rapid Curing (RC) is primarily used for tasks requiring speedy repairs, such as filling potholes or conducting surface treatments. Medium Curing (MC) serves as a binding layer to enhance the adhesion of subsequent layers, making it a popular choice for prime coats before the application of asphalt. On the other hand, Slow Curing (SC) is ideal for preparing cold mixes, as its longer curing time allows for better moisture management and mixture handling.

Examples & Analogies

Imagine if you’re baking. Rapid Curing is like a microwave cake that cooks quickly—great for when you need dessert fast! Medium Curing is like traditional frosting that needs a solid base before you spread it—ideal for holding the cake together. Slow Curing is akin to a dense cake that requires careful baking to ensure it doesn't dry out—important for larger batch preparations.

Environmental Considerations

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

10.4.3 Environmental Considerations:

- Cutbacks release volatile organic compounds (VOCs), hence less preferred now due to environmental regulations.

Detailed Explanation

While cutback bitumen has practical applications, there are environmental concerns associated with its use. The solvents that make cutback bitumen workable release Volatile Organic Compounds (VOCs) into the atmosphere during application and curing. VOCs can contribute to air pollution and have health implications. As a result, many regions are reducing or eliminating the use of cutbacks in favor of more environmentally friendly alternatives, like emulsified asphalt, which does not release VOCs in the same way.

Examples & Analogies

This situation can be likened to using wood for a fire. While burning wood can provide warmth and light, it produces smoke and pollutants. As we become more aware of air quality, we look for cleaner alternatives, like electric heaters, which provide the same comfort without the negative side effects.

Key Concepts

-

Cutback Bitumen: A diluted form of bitumen for easier application at lower temperatures.

-

Types of Cutbacks: Includes RC, MC, and SC distinguished by their solvent types and curing speed.

-

Environmental Impact: Recognizes the release of VOCs from cutbacks as a significant concern in construction.

Examples & Applications

Cutback bitumen allows for road repairs to be done quickly in cooler weather without compromising quality.

An example of RC in action is using a rapid curing bitumen for pothole repairs, allowing crews to work efficiently during cold seasons.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cutback bitumen's the way to go, in the cold it makes repairs flow.

Stories

Imagine a construction crew ready to fix a road on a chilly morning. They reach for cutback bitumen, knowing it's the solution that flows smoothly even at low temps, getting the job done without delay.

Memory Tools

Remember the phrase 'RC for Repair, MC for Prime, SC for Cold'. This will help you recall the main uses of each type!

Acronyms

Remember **RMC** for Rapid, Medium, and Slow curing cutbacks.

Flash Cards

Glossary

- Cutback Bitumen

Bitumen diluted with volatile solvents to reduce viscosity for easier application.

- Volatile Organic Compounds (VOCs)

Chemical compounds that can evaporate at room temperature and contribute to air pollution.

- Rapid Curing (RC)

Type of cutback bitumen that uses petrol or naphtha as a solvent for quick applications.

- Medium Curing (MC)

Cutback bitumen that uses kerosene as a solvent, used for prime coats.

- Slow Curing (SC)

Cutback bitumen that uses diesel or heavy oils for cold mix preparation.

Reference links

Supplementary resources to enhance your learning experience.