Cement Concrete for Pavement Construction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Types of Concrete Pavements

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore the different types of concrete pavements. Can anyone tell me what Plain Cement Concrete Pavement is?

Isn't it the one without any reinforcement?

Correct! PCC is used for light to medium traffic. What about Reinforced Cement Concrete Pavement?

It includes steel reinforcement to handle heavier loads, right?

Yes! And it reduces the number of joints needed. Now, who can tell me about Prestressed Concrete Pavement?

It uses pre-tensioned or post-tensioned tendons to counteract tensile stresses.

Exactly! It has a higher initial cost but offers a long service life. Now let's summarize: PCC is for light traffic, RCC is reinforced for heavy loads, and Prestressed is for long-lasting performance.

Materials Used in Cement Concrete Pavement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Materials are crucial in pavement construction. Can someone name a type of cement commonly used?

Ordinary Portland Cement, right?

Right! It should conform to certain standards. What about aggregates?

Coarse aggregates are typically crushed stone, and fine aggregates can be natural sand.

Good! They must be clean and free from harmful materials. Can anyone tell me the role of water?

It has to be potable and free from contamination.

Exactly! Lastly, admixtures like superplasticizers improve concrete performance. Let’s summarize: OPC, clean aggregates, good water, and effective admixtures make a strong pavement.

Construction Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's move on to construction techniques. What equipment is often used for laying concrete?

Paver machines, right?

Correct! And what about compaction?

Vibrators are used to eliminate air voids, and screeding helps control the surface level.

Exactly! It's vital to compact thoroughly. Can someone explain the curing methods?

Water curing and membrane curing are common methods to ensure the concrete stays hydrated.

Very well! In summary, different machinery is used for laying, and curing methods ensure concrete develops its strength.

Quality Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Quality control is critical in construction. What tests do we perform on fresh concrete?

The slump test to check workability!

Correct! And what about hardened concrete?

We check compressive strength and flexural strength.

Yes, and we also conduct core testing for in-situ quality. In conclusion, performing various tests at different stages ensures the pavement lasts.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Cement concrete pavements, or rigid pavements, are vital for modern infrastructure due to their durability and strength. This section covers the types and materials of concrete pavements, the design mix, construction techniques, and maintenance methods to ensure longevity and performance.

Detailed

Cement Concrete for Pavement Construction

Cement concrete pavements, also referred to as rigid pavements, play a crucial role in contemporary road infrastructure. They are designed to handle high traffic loads and extreme weather conditions while providing structural strength and durability over time.

Key Components Covered:

- Types of Concrete Pavements: Plain Cement Concrete Pavement (PCC), Reinforced Cement Concrete Pavement (RCC), Prestressed Concrete Pavement, and Continuously Reinforced Concrete Pavement (CRCP), with varying degrees of reinforcement and jointing.

- Materials Used: Cement types (Ordinary Portland Cement), aggregates (coarse and fine), water quality, and admixtures to enhance concrete properties.

- Design of Mix: Differences between nominal and design mixes, target strengths, water-cement ratios, and testing methods to achieve workability and durability.

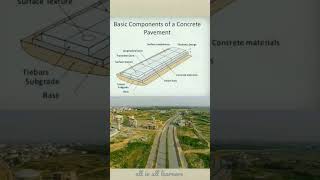

- Subgrade and Sub-base Preparation: Importance of proper compaction and drainage in the foundation layer.

- Concrete Batching and Mixing: Emphasis on accuracy in batching and thorough mixing techniques.

- Laying and Compaction: Use of machinery for efficient laying and ensuring proper compaction.

- Finishing Techniques: Various methods for achieving surface finish and texture.

- Curing Methods: Duration and types of curing to ensure hydration and strength development.

- Joints and Sealants: Roles of expansion, contraction, construction, and warpage joints in managing stress and movements.

- Reinforcement and Quality Control: Structural reinforcement and testing methods to maintain quality standards.

- Modern Construction Techniques: Use of innovative methods like slip form paving and roller compacted concrete.

- Maintenance Strategies: Importance of preventive and corrective maintenance to extend pavement life.

- Environmental Considerations: Use of sustainable materials and practices to minimize ecological impact.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Cement Concrete Pavements

Chapter 1 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Cement concrete pavements, also known as rigid pavements, are a crucial component of modern road infrastructure. They provide high structural strength, long service life, and excellent durability, particularly in areas with heavy traffic loads and extreme climatic conditions. Unlike flexible pavements which derive their strength primarily from the bituminous layers, rigid pavements transfer loads through slab action and are supported by a well-prepared sub-base. This chapter explores the complete process of cement concrete pavement construction — from material selection to laying, finishing, and curing. Emphasis is also laid on joints, reinforcement, quality control, and modern construction techniques to ensure high performance and cost-efficiency.

Detailed Explanation

Cement concrete pavements, often called rigid pavements, play a vital role in today's road systems. They are specifically engineered to withstand heavy traffic and harsh weather while lasting many years. The term 'rigid' refers to their ability to distribute loads evenly across the surface, which is essential for maintaining stability. Unlike flexible pavements that depend on asphalt layers for strength, rigid pavements utilize concrete slabs supported by a solid foundational sub-base. This segment of the chapter introduces the comprehensive process involved in constructing these pavements, covering everything from selecting appropriate materials, the laying process, finishing techniques, and curing methods. It highlights the importance of various factors, such as joints and reinforcement, which contribute to the pavement's overall effectiveness and longevity.

Examples & Analogies

Think of rigid concrete pavements like the foundation of a house. Just like how a strong foundation helps support the entire structure against storms and earthquakes, a well-built concrete pavement supports vehicles against heavy loads and varying weather conditions. Both require careful planning and high-quality materials to ensure they serve their purpose effectively.

Types of Concrete Pavements

Chapter 2 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

-

Plain Cement Concrete Pavement (PCC)

• No reinforcement

• Suitable for light to medium traffic loads

• Relies on expansion, contraction, and construction joints to manage cracking -

Reinforced Cement Concrete Pavement (RCC)

• Includes steel reinforcement

• Resists temperature stresses and heavy loading

• Reduced number of joints -

Prestressed Concrete Pavement

• Use of pre-tensioned or post-tensioned tendons

• Counteracts tensile stresses

• High initial cost but long service life -

Continuously Reinforced Concrete Pavement (CRCP)

• Continuous steel reinforcement

• No transverse joints (except at structures)

• Controls crack widths and locations

Detailed Explanation

This section details four primary types of cement concrete pavements, each designed for different uses and conditions.

- Plain Cement Concrete Pavement (PCC) is used in areas where traffic is limited; it doesn't have any reinforcement and relies on techniques to handle cracking.

- Reinforced Cement Concrete Pavement (RCC) incorporates steel reinforcements which significantly improve its capacity to handle heavy traffic and temperature variations, and it has fewer joints, reducing susceptible areas for cracks.

- Prestressed Concrete Pavement involves pre-tensioning or post-tensioning techniques that allow these pavements to better manage tensile stresses, which makes them ideal for demanding conditions, despite their higher cost.

- Continuously Reinforced Concrete Pavement (CRCP) features a continuous steel network that eliminates most joints, effectively controlling crack features and enhancing durability. Each type provides solutions tailored toward specific traffic demands and environmental circumstances.

Examples & Analogies

Consider these types of concrete pavements like different types of shoes for varying occasions. A pair of sandals may serve well for a light stroll (PCC) while a sturdy hiking boot (RCC) is necessary for challenging terrain. Just as you wouldn't wear flip-flops for a mountain hike, each pavement type is designed for its own set of circumstances and demands, chosen based on expected use.

Materials Used in Cement Concrete Pavement

Chapter 3 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

16.2.1 Cement

• Ordinary Portland Cement (OPC) – 43 or 53 grade

• Should conform to IS: 269 or IS: 12269

• Should be fresh and stored properly

16.2.2 Aggregates

• Coarse Aggregates: Crushed stone, angular in shape; size usually 20 mm down

• Fine Aggregates: Natural sand or crushed stone sand

• Conforming to IS: 383

• Free from deleterious materials

16.2.3 Water

• Potable water free from oils, acids, alkalis, salts, and organic matter

• As per IS: 456

16.2.4 Admixtures

• Water reducers, retarders, superplasticizers, or air-entraining agents

• Improves workability, durability, and resistance to freeze-thaw.

Detailed Explanation

The quality of materials used in constructing cement concrete pavements is fundamental to the strength and durability of the project.

- Cement: The primary binding material, typically Ordinary Portland Cement (OPC), must meet valid standards and be in good condition to perform well.

- Aggregates: These represent the bulk of the concrete mix, with coarse aggregates usually being crushed stone and fine aggregates may include sand. They need to be free of impurities to ensure quality.

- Water: Clean, potable water is crucial, containing no harmful substances that could weaken the concrete.

- Admixtures: Added to enhance properties like workability and resistance to environmental stresses. These can range from water reducers to agents preventing freeze-thaw damage. Each of these components must be selected carefully to create a durable and efficient pavement.

Examples & Analogies

Think of the materials in concrete like the ingredients in a recipe. Just as high-quality ingredients lead to a delicious cake, using the best materials (cement, aggregates, water, and admixtures) results in a strong and lasting pavement. If you use spoiled eggs or cheap flour, the cake might fall apart. Similarly, if the materials in concrete are subpar, the pavement will not hold up under stress.

Design Considerations for Concrete Mix

Chapter 4 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Nominal Mix vs. Design Mix

– Nominal mix for low-grade concrete (e.g., 1:2:4)

– Design mix based on structural design and strength requirements

• Target Strength

– Achieved by calculating characteristic compressive strength and adding a margin for quality control

• Water-Cement Ratio

– Critical for strength and durability

– Typical range: 0.4 to 0.5

• Workability

– Determined using slump test

– Slump values: 20–40 mm for pavements

• Durability Considerations

– Resistance to abrasion, sulphate attack, and freeze-thaw cycles.

Detailed Explanation

This section delves into various design factors that impact the concrete mix.

- Nominal Mix vs. Design Mix: A nominal mix uses a predefined ratio for basic strength, while a design mix is tailored based on specific structural requirements ensuring optimal performance.

- Target Strength: The intended strength of the concrete is determined by calculating the compressive strength and adding an extra margin to ensure quality.

- Water-Cement Ratio: This is crucial since too much or too little water can impact the strength and durability of the pavement. A ratio between 0.4 to 0.5 is generally optimal.

- Workability: This refers to how easy the concrete is to work with and is typically measured through a slump test, with acceptable slump values for pavements ranging from 20-40 mm.

- Durability Considerations: Pavements must resist wear and environmental challenges like sulfate attack or freeze-thaw cycles, highlighting the importance of quality in the mix design.

Examples & Analogies

Consider designing a concrete mix like choosing the right combination of ingredients for a smoothie. If you want it thick and creamy, you need to balance the amount of fruit (cement), liquids (water), and any extras for flavor or texture (admixtures). If you don't measure correctly, your smoothie might end up too watery or too lumpy, just like poorly mixed concrete can lead to weak pavements.

Subgrade and Sub-base Preparation

Chapter 5 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

16.4.1 Subgrade

• Properly compacted to 95% of Modified Proctor Density

• Should be well-drained and free from organic material

16.4.2 Sub-base

• Often made from granular material or lean concrete

• Thickness: 100 mm to 150 mm

• Acts as a working platform and load transfer medium.

Detailed Explanation

Preparing the subgrade and sub-base is an essential step in concrete pavement construction.

- Subgrade: This is the soil layer beneath the pavement and needs to be carefully compacted to ensure it withstands the loads placed upon it. It should be stable, well-drained, and free of any organic materials that might decompose or shift.

- Sub-base: This layer sits on top of the subgrade and is usually composed of coarse material or lean concrete. Its primary purpose is to provide a stable working platform for the concrete mix and help distribute the loads evenly. The appropriate thickness usually ranges from 100 mm to 150 mm, enhancing the overall strength and stability of the pavement.

Examples & Analogies

Think of the subgrade and sub-base like the base of a cake. Just like a thin, unstable cake layer might cause the dessert to collapse, a poorly prepared subgrade and sub-base can lead to pavement failure. The stronger and more stable these foundational layers are, the better the ‘cake’ (in this case, the pavement) will turn out.

Laying and Compaction of Concrete

Chapter 6 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

16.6.1 Equipment Used

• Paver machines (slip-form or fixed-form types)

• Vibrators (needle or surface vibrators)

16.6.2 Procedure

• Concrete laid in panels

• Compacted and vibrated thoroughly to eliminate air voids

• Screeding for surface level control

16.6.3 Edge Support

• Temporary side forms or pre-set forms ensure edge stability

• Forms must be rigid and properly aligned.

Detailed Explanation

The actual placement of concrete is a critical step that involves several techniques and equipment.

- Equipment Used: Specialized machines are employed for laying concrete. Paver machines are classified into two types—slip-form and fixed-form—each offering precision in shaping the slab. Vibrators are used to ensure the concrete is evenly distributed and to eliminate air pockets that can weaken the final product.

- Procedure: Concrete is typically poured in sections or panels, and comprehensive compaction and vibration processes take place to achieve the desired density. After pouring, screeding is employed to ensure the surface is level and smooth.

- Edge Support: To maintain straight edges and prevent collapse, temporary forms are installed that must be sturdy and perfectly aligned. This is essential for achieving not just the structural integrity but also the aesthetics of the pavement.

Examples & Analogies

Imagine pouring a thick batter into a cake tin. Just as you would pat and shake the tin to eliminate air bubbles and ensure an even surface, the laying and compaction of concrete requires similar techniques. Additionally, the tin itself serves to hold the batter in shape until it's solid, which is exactly what the temporary forms do for the pavement.

Finishing of Surface

Chapter 7 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Initial Finishing: Done using longitudinal and transverse screeds

• Final Finishing: Texturing using burlap drag, broom finish, or tining for skid resistance

• Surface tolerance: ±3 mm over 3 m straightedge

Detailed Explanation

Surface finishing is the final step before the pavement is cured and is crucial for its usability and safety.

- Initial Finishing: This is achieved using screeds, which are tools that level the surface initially. Longitudinal and transverse screeds work together to create a flat surface.

- Final Finishing: Additional techniques, such as dragging burlap or using a broom, are applied for texturing the surface. This texturing is important for skid resistance, especially in wet conditions, providing safety for vehicles.

- Surface Tolerance: Maintaining a precise surface tolerance is critical; typically, the finished surface should not vary more than ±3 mm across a 3 m straightedge. This ensures evenness and quality in the final product.

Examples & Analogies

Think of finishing concrete like icing a cake. Just as you want to smooth out the icing while ensuring it's not too thick or too thin, the surface of concrete needs precise finishing. The texturing, like using a fork to create grooves in icing, helps enhance grip and make sure the pavement performs well under different weather conditions.

Key Concepts

-

Types of Concrete Pavement: Various forms of concrete pavements including PCC, RCC, and Prestressed.

-

Materials Used: Key materials in construction such as cement, aggregates, water, and admixtures.

-

Construction Techniques: Methods and machinery involved in laying, mixing, and curing concrete.

-

Quality Control: Procedures to ensure structural integrity and durability of the pavement.

Examples & Applications

Plain Cement Concrete Pavement (PCC) is commonly used in parking lots due to its low traffic requirements.

Reinforced Cement Concrete Pavement (RCC) is often utilized in highways where heavier vehicles operate.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

PCC is plain with no steel inside; light traffic’s where it will abide.

Stories

Imagine a city where heavy trucks rumble over roads made of RCC, which stands firm and strong because it has iron bars inside, allowing it to take the weight.

Memory Tools

Remember the acronym ‘PCR’ to recall Pavement, Cure, Reinforcement for the key aspects of concrete pavements.

Acronyms

C.A.W.A

Cement

Aggregates

Water

Admixtures are the core ingredients for concrete.

Flash Cards

Glossary

- Pavement

A durable surface made for roadways, typically using materials like concrete or asphalt.

- Admixture

A material added to concrete to enhance its properties.

- Curing

The process of maintaining adequate moisture in concrete to allow for proper hydration.

- Compaction

The process of increasing the density of soil or pavement material to improve its load-bearing capacity.

- Reinforcement

Steel bars or mesh included in concrete to increase its tensile strength.

Reference links

Supplementary resources to enhance your learning experience.