Curing of Concrete Pavement

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

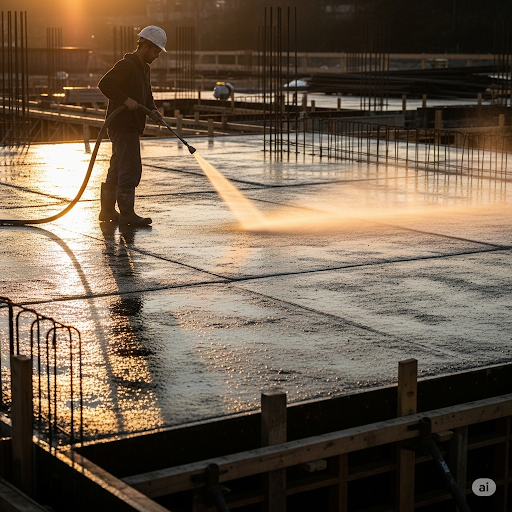

Water Curing Methods

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive into water curing, which can be done by various methods like sprinkling, ponding, or using wet burlap. Who can explain what sprinkling involves?

Sprinkling is where water is sprayed onto the concrete surface continuously to keep it wet.

Exactly, and why do we want to maintain moisture on the surface?

It helps with the hydration process of the cement, leading to stronger concrete.

Correct! Can anyone think of why ponding might be preferred in certain situations?

Ponding creates a standing layer of water, which I think is good for preventing evaporation.

Yes! Keeping evaporation at bay is vital. Also remember, the duration we maintain any of these methods greatly affects the concrete quality. How long is the minimum curing period?

At least 7 days, right?

Exactly! Well done everyone. Water curing is integral for strong pavements.

Membrane Curing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about membrane curing. Can someone explain what it involves?

It involves applying a curing compound that forms a film over the concrete to keep it moist.

Great! This is particularly relevant when water curing isn't accessible. Why is retaining moisture important here?

To ensure the cement hydrates properly without evaporating too quickly.

Well put! And do you think membrane curing can be used in combination with other methods?

Yes, I think it can be used alongside water curing to enhance moisture retention.

Precisely! It can be very effective, especially in challenging weather conditions.

Steam Curing and Curing Duration

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we’ll discuss steam curing. Can anyone tell me when steam curing is typically used?

It's often used in precast concrete applications, right?

Exactly! Steam curing accelerates the curing process. Why might this be necessary?

In colder weather, it helps speed up hydration when it would typically slow down.

Spot on! And what about the curing duration we've talked about—what factors influence that?

Hot or windy conditions might require longer curing times to prevent drying out.

Absolutely right! The environmental conditions can greatly affect our curing strategy.

So it all comes down to preventing cracks, ensuring strength—all super important!

Exactly! Excellent discussion today, everyone!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Effective curing of concrete pavements is crucial for maintaining their properties and ensuring longevity. Methods include water curing through sprinkling or ponding, membrane curing with compounds, and steam curing in precast applications. Proper duration of curing is emphasized for optimal performance.

Detailed

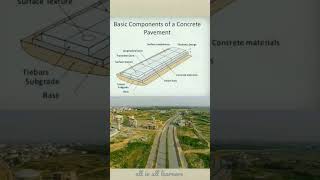

Curing of Concrete Pavement

Curing plays a pivotal role in the construction of cement concrete pavements, ensuring that the concrete achieves its required strength and durability. Curing methods can be divided into three primary categories:

- Water Curing: This method involves using sprinkling, ponding, or covering the concrete with wet burlap to keep it moist. Water curing is effective in preventing the evaporation of moisture from the surface, which is critical for hydration of the cement particles.

- Membrane Curing: This involves applying curing compounds to the surface of the concrete to form a film that retains moisture. It is particularly useful in situations where immediate water curing is not feasible and can be more efficient in maintaining the necessary hydration levels.

- Steam Curing: Mostly used in precast applications, steam curing accelerates the curing process by introducing steam to increase the ambient temperature, thus enhancing hydration. This method is especially beneficial in cold weather conditions where hydration can be slowed significantly.

Curing Duration

The standard recommendation for curing duration is a minimum of 7 days. However, in hot or windy conditions, extended curing periods are necessary to prevent premature drying and potential cracking of the surface. Proper curing not only improves strength but also enhances the overall performance of the pavement, making it a critical step in the construction process.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Methods of Curing

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Water Curing – Sprinkling, ponding, or wet burlap

- Membrane Curing – Application of curing compounds

- Steam Curing – Used in precast applications

Detailed Explanation

Curing is a process that helps concrete achieve its desired strength and durability. There are three main methods of curing concrete:

1. Water Curing - This involves maintaining moisture on the surface of the concrete through techniques like sprinkling water, ponding, or covering it with wet burlap to keep it hydrated. This is essential for preventing the concrete from drying out too quickly, which can cause cracks.

- Membrane Curing - This method involves applying special curing compounds that form a film over the concrete surface, minimizing evaporation. This is especially useful in situations where water curing is not feasible due to weather conditions.

- Steam Curing - Typically used in precast concrete applications, this method involves applying steam to accelerate the curing process. It creates a warm, moist environment that helps the concrete to strengthen faster.

Examples & Analogies

Think of curing concrete like making a perfect cake. Just like a cake needs moisture while it bakes to rise properly and not dry out, concrete needs moisture during its curing phase to ensure it sets correctly and reaches its full strength. Each curing method is like a different baking technique you might use, depending on the ingredients and tools you have available.

Curing Duration

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Minimum 7 days (or as per mix requirement)

• Extended curing in hot or windy conditions

Detailed Explanation

The duration of curing is critical for the concrete to develop the strength it needs. The standard minimum duration for curing concrete is 7 days, although this can vary based on the specific mix used. During this time, it's important to ensure that the concrete remains moist.

In challenging conditions, such as high temperatures or wind, curing duration might need to be extended. This is because these environmental factors can cause the water in the concrete to evaporate too quickly, leading to incomplete hydration and cracking.

Examples & Analogies

Consider a plant that needs consistent watering to grow strong. If you only water it for a few days and then stop, or if you let the sun completely dry it out, it won’t flourish. Similarly, concrete requires consistent moisture for a minimum period to ensure it cures properly and reaches its maximum strength.

Key Concepts

-

Curing Importance: Curing of concrete is crucial to achieve intended strength and durability.

-

Water Curing Methods: Involves methods like sprinkling and ponding to maintain moisture.

-

Membrane Curing: Utilizes compounds to form films for moisture retention.

-

Steam Curing: Accelerates hydration for precast applications.

-

Curing Duration: General recommendation of a minimum of 7 days.

Examples & Applications

Using wet burlap for water curing on a hot day to prevent rapid evaporation.

Employing membrane curing in a situation where water curing isn't practical due to site constraints.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If concrete's dry, give it a try, sprinkle with water, let it satisfy.

Stories

Imagine a brave little concrete slab, exposed to the sun, feeling thirsty. As the construction crew remembers to sprinkle it regularly, the slab smiles, growing stronger and better.

Memory Tools

WMS: Water, Membrane, Steam – remember the types of curing!

Acronyms

WMS for Water, Membrane, and Steam curing methods.

Flash Cards

Glossary

- Water Curing

A method that keeps concrete moist using methods like sprinkling or ponding.

- Membrane Curing

Applying a curing compound to form a film that retains moisture on the concrete surface.

- Steam Curing

A method of curing where steam is used to accelerate the hydration of concrete, particularly in precast applications.

- Curing Duration

The time period that concrete must be cured to achieve its desired strength and prevent cracking, usually a minimum of 7 days.

Reference links

Supplementary resources to enhance your learning experience.