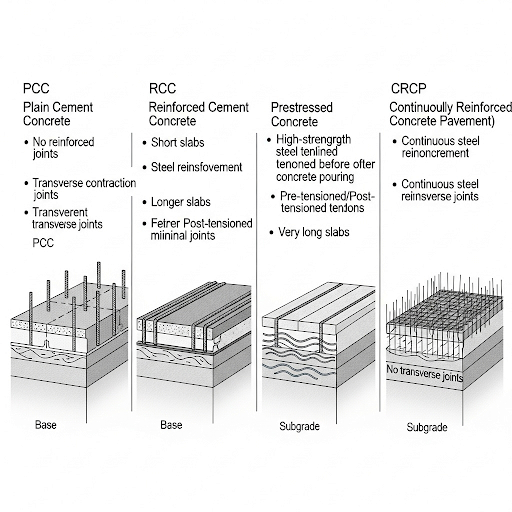

Types of Concrete Pavements

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Plain Cement Concrete Pavement (PCC)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss Plain Cement Concrete Pavement or PCC. Can anyone tell me what they think PCC involves?

I think it means concrete without any reinforcement.

Exactly! PCC is indeed made of concrete without any added steel reinforcement. This makes it suitable for light to medium traffic loads. What do you think are examples of places where it could be used?

Like residential driveways or small parking lots?

Yes! PCC is very common in such applications. Now, how does it manage cracking?

I remember you said something about joints?

Correct! We use expansion, contraction, and construction joints to manage any potential cracking from temperature changes. Great job! So, can anyone summarize what we've talked about PCC?

PCC is unreinforced, used in lighter traffic, and manages cracking with joints.

Perfect summary!

Reinforced Cement Concrete Pavement (RCC)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's move on to Reinforced Cement Concrete Pavement, or RCC. Who can explain what it adds to PCC?

Is it the steel reinforcement?

Yes! RCC includes steel reinforcement which helps it resist temperature stresses and heavier loads. Why do you think having less joints is a benefit?

Maybe it makes it stronger overall and reduces maintenance?

Exactly! Fewer joints mean fewer points that could wear down and require maintenance. Can anyone think of where RCC would be more suitable than PCC?

On highways where there’s more traffic?

Spot on! Great job! Can anyone summarize the benefits of RCC?

RCC has steel reinforcement, handles heavier traffic and temperature changes, and has fewer joints.

Prestressed Concrete Pavement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we'll discuss Prestressed Concrete Pavement. What makes it different from the previous types?

Does it use the tensioning of tendons?

That's right! Prestressed Concrete either uses pre-tensioned or post-tensioned tendons to counteract tensile stresses. This leads to high durability. What about the initial cost? How does it compare?

I think it costs more initially?

Correct! Despite the higher initial cost, the long service life it provides makes it economically favorable in the long run. Can someone explain situations where this type would be beneficial?

Maybe in areas with heavy commercial traffic?

Exactly! Summarize the characteristics of Prestressed Concrete.

It’s tensioned, costs more initially, lasts longer and is great for heavy loads.

Continuously Reinforced Concrete Pavement (CRCP)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's explore Continuously Reinforced Concrete Pavement or CRCP. What differentiates it from RCC?

It has continuous steel reinforcement?

Right! This allows CRCP to control crack widths and locations better because there are no transverse joints, except at structures. Why do you think this is beneficial?

It seems like it would make maintenance easier?

Absolutely! Less jointing leads to fewer opportunities for deterioration. Can someone explain again what the continuous reinforcement achieves?

It keeps cracking under control and enhances durability.

Lovely summary. Overall, can we wrap up the CRCP characteristics?

It features continuous reinforcement, creating fewer joints and controlling cracks better.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section delves into four primary types of concrete pavements: Plain Cement Concrete (PCC) suited for lighter loads, Reinforced Cement Concrete (RCC) which provides increased load resistance, Prestressed Concrete that counteracts tensile stresses, and Continuously Reinforced Concrete (CRCP) which minimizes joints while effectively controlling cracks.

Detailed

Types of Concrete Pavements

Cement concrete pavements, often referred to as rigid pavements, are essential components of road infrastructure due to their durability and structural strength. This section specifically evaluates four types of concrete pavements:

Plain Cement Concrete Pavement (PCC)

- Features: Consists of concrete without any reinforcement, making it most suited for light to medium traffic.

- Structural considerations: Utilizes expansion, contraction, and construction joints to manage any potential cracking that may occur from temperature changes or load stresses.

Reinforced Cement Concrete Pavement (RCC)

- Features: This type includes steel reinforcement to enhance its ability to resist temperature-induced stresses and heavy loading.

- Advantages: Reduced joint requirements compared to PCC, which ultimately contributes to a longer lifespan.

Prestressed Concrete Pavement

- Features: Incorporates pre-tensioned or post-tensioned tendons within the concrete, which work to counteract tensile stresses effectively.

- Economic considerations: While it has a higher initial cost, it offers a longer service life due to its superior performance.

Continuously Reinforced Concrete Pavement (CRCP)

- Features: Characterized by continuous steel reinforcement with no transverse joints (with exceptions at structures).

- Benefits: Controls the widths and locations of cracks, thus enhancing overall pavement performance and longevity.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Plain Cement Concrete Pavement (PCC)

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• No reinforcement

• Suitable for light to medium traffic loads

• Relies on expansion, contraction, and construction joints to manage cracking

Detailed Explanation

Plain Cement Concrete Pavement, or PCC, is a type of rigid pavement that does not use any form of reinforcement like steel bars. It is versatile and primarily designed for areas experiencing light to medium traffic. To accommodate changes in temperature and to minimize cracking that may occur, PCC incorporates various types of joints, such as expansion, contraction, and construction joints. These joints allow for slight movements in the concrete, thus preventing major cracks from forming.

Examples & Analogies

Imagine a continuous stretch of ice on a frozen lake. Without gaps, the ice can crack as it expands and contracts with temperature changes. The joints in PCC are like the natural cracks formed on the ice—a way to manage stress and avoid larger fractures. If the ice had no cracks, it would shatter in large sections as the temperature fluctuated.

Reinforced Cement Concrete Pavement (RCC)

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Includes steel reinforcement

• Resists temperature stresses and heavy loading

• Reduced number of joints

Detailed Explanation

Reinforced Cement Concrete Pavement, or RCC, incorporates steel reinforcement within the concrete. This reinforcement helps the pavement better withstand temperature fluctuations and heavy loads from vehicles. Additionally, because the steel reinforcement allows the pavement to handle stresses more effectively, RCC can reduce the number of necessary joints compared to PCC, resulting in a smoother surface with fewer interruptions.

Examples & Analogies

Think of a thick rubber band. When stretched, it can accommodate some distance without breaking. Similarly, the steel within RCC acts like that rubber band, allowing the concrete to handle more weight and stress without cracking extensively. Fewer joints mean a more cohesive and stable driving surface, akin to having fewer interruptions on a long road.

Prestressed Concrete Pavement

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Use of pre-tensioned or post-tensioned tendons

• Counteracts tensile stresses

• High initial cost but long service life

Detailed Explanation

Prestressed Concrete Pavement is a specialized type of pavement that uses either pre-tensioned or post-tensioned steel tendons to create internal stresses that counteract external tensile forces. This design significantly enhances the pavement's durability and load-bearing capacity. Although the initial construction costs for prestressed pavements can be higher, they offer a longer service life, reducing maintenance and replacement costs over time.

Examples & Analogies

Consider a tightly pulled rubber band that won’t easily snap. In prestressed concrete, the tendons serve a similar function—they keep the concrete under tension so that it stays strong under stress. Initially, you might pay more to set it up, but like investing in a high-quality tool, it saves you money and effort over time by lasting longer and requiring less repair.

Continuously Reinforced Concrete Pavement (CRCP)

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Continuous steel reinforcement

• No transverse joints (except at structures)

• Controls crack widths and locations

Detailed Explanation

Continuously Reinforced Concrete Pavement, or CRCP, features a continuous steel reinforcement throughout the concrete slab. This method eliminates the need for transverse joints except at structural transitions. The continuous nature of the reinforcement helps control the size and location of any cracking, making the pavement more reliable and reducing the maintenance that comes with traditional jointed pavements.

Examples & Analogies

Picture a strong, unbroken chain holding up a heavy load: the absence of weak links means the entire structure can handle stress better. Similarly, the continuous reinforcement in CRCP creates a resilient surface that can flex and accommodate movement without forming significant cracks, providing a stable and long-lasting road surface.

Key Concepts

-

Plain Cement Concrete Pavement (PCC): A basic pavement type with no reinforcement suitable for lighter loads.

-

Reinforced Cement Concrete Pavement (RCC): Pavement with steel reinforcement for improved strength.

-

Prestressed Concrete Pavement: Features tensioned tendons to resist tensile stresses.

-

Continuously Reinforced Concrete Pavement (CRCP): Offers continuous reinforcement to manage cracking.

Examples & Applications

PCC is often used for small sidewalks and residential driveways.

RCC is commonly used on urban roads and highways where heavy traffic is expected.

Prestressed Concrete Pavement is ideal for airport runways due to the high loads.

CRCP is utilized in continuous road stretches to minimize maintenance and enhance durability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

PCC for parking, light and bright, / RCC less joints, heavy loads in sight.

Stories

Once there was a road that faced heavy rain. It cracked under pressure until RCC came to ease the strain, with steel bars and reduced joints, relief it did gain.

Memory Tools

Remember 'CRCP' as 'Continuous Roads Control Cracks Perfectly'.

Acronyms

Use 'P-R-C' for the pavements

Plain

Reinforced

and Continually reinforced.

Flash Cards

Glossary

- Plain Cement Concrete Pavement (PCC)

A type of concrete pavement without reinforcement, suitable for light to medium traffic loads.

- Reinforced Cement Concrete Pavement (RCC)

Concrete pavement that includes steel reinforcements, enhancing resistance to heavy loads.

- Prestressed Concrete Pavement

Concrete pavement that uses pre-tensioned or post-tensioned tendons to counteract tensile stresses.

- Continuously Reinforced Concrete Pavement (CRCP)

Concrete pavement characterized by continuous steel reinforcement, minimizing joints for better crack control.

Reference links

Supplementary resources to enhance your learning experience.