Plain Cement Concrete Pavement (PCC)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to PCC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about Plain Cement Concrete Pavement, or PCC. As a rigid pavement, it provides significant structural strength, but can anyone tell me what makes it different from flexible pavements?

I think it’s because PCC doesn’t use any bituminous layers for support.

Exactly! PCC transfers loads through slab action and relies on a well-prepared sub-base. What are the types of traffic loads suitable for PCC?

It’s suitable for light to medium traffic loads!

Correct! That’s key to its application. PCC also manages cracking through joint types. Who can name some of them?

Expansion joints, contraction joints, and construction joints!

Great recall! Remember, these joints are crucial for accommodating movements and preventing issues.

To summarize, PCC is vital for projects with low to moderate traffic and is distinguished by its absence of reinforcement and management of cracking via joints.

Importance of Cracking Management

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's examine why managing cracking is so important in PCC. What happens if we don’t use these joints?

The concrete could crack in uncontrolled ways?

Exactly! Without joints, stresses would cause random cracking. Now, who can explain how expansion joints function?

They accommodate thermal expansion of the concrete, allowing it to expand in heat.

Right on! Now, contraction joints are designed for the opposite—what do you think they do?

They help control where cracks appear during concrete shrinking.

Spot on! Proper joint placement is critical for durability. In summary, joints are key for the longevity of PCC, preventing random cracking and ensuring structural integrity.

Conclusion of PCC Features

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To wrap up our discussion on Plain Cement Concrete Pavements, can someone recall the main characteristic that sets PCC apart?

No reinforcement—that's what makes it different from RCC!

Perfect! And what types of traffic is it designed for?

Light to medium traffic loads.

Exactly! And what systems does it use to manage potential cracking?

Through expansion, contraction, and construction joints.

Correct! To summarize, PCC is essential for practical highway construction solutions that require strength and durability without extensive reinforcement. This knowledge will be crucial as we transition into discussing reinforced concrete pavements.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

PCC serves as an effective solution for road construction, primarily suitable for light to medium traffic. Unlike reinforced types, it doesn't utilize steel for strength, relying instead on joints to accommodate movement and control cracking. It's essential to understand these features for effective pavement design and maintenance.

Detailed

Overview of Plain Cement Concrete Pavement (PCC)

Plain Cement Concrete Pavements (PCC), also termed rigid pavements, are utilized extensively in construction for their high strength and durability, especially suitable in areas facing moderate traffic loads.

Key Features of PCC:

- No Reinforcement: PCC does not use steel reinforcement, making it a cost-effective solution for less trafficked roads.

- Cracking Management: It utilizes various joints—included expansion, contraction, and construction joints—that allow for movement due to temperature variations and minimize cracking risks.

- Traffic Suitability: Especially ideal for light to medium traffic applications, making it popular in urban settings and smaller roads.

The significance of PCC lies in its fundamental construction principles and basic design, preparing students for further understanding of reinforced pavements (RCC) and modern pavement techniques detailed later in the chapter.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition and Characteristics

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• No reinforcement

• Suitable for light to medium traffic loads

• Relies on expansion, contraction, and construction joints to manage cracking

Detailed Explanation

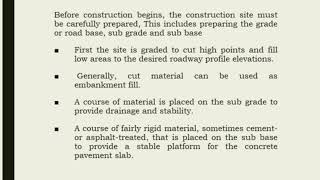

Plain Cement Concrete Pavement, often referred to as PCC, is a type of pavement that does not incorporate any steel reinforcement. This means that the concrete is poured and forms a solid slab on its own, which is effective for roads with lighter to medium traffic volumes. PCC is designed with joints—expansion and contraction joints—which help control the cracking that occurs due to temperature changes and the natural movement of the concrete. These joints allow the slabs to expand and contract without causing damage.

Examples & Analogies

Think of PCC like a well-prepared cake. Just as a cake batter needs the right consistency and structure to rise and bake well, the concrete mix in PCC must be precise to withstand traffic loads without reinforcement. The 'joints' act like careful cuts in the cake that let it expand without cracking.

Traffic Load Suitability

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Suitable for light to medium traffic loads

Detailed Explanation

PCC is specifically engineered to handle lower traffic volumes compared to other types of concrete pavements that are reinforced or prestressed. This makes it an economical choice for residential streets, parking lots, and rural roads where heavy vehicle traffic is not a concern. By understanding the expected traffic load, engineers can decide if PCC is an appropriate choice for a specific project.

Examples & Analogies

Imagine a quiet neighborhood street versus a busy highway. The neighborhood street, which experiences mostly cars and light trucks, can efficiently use PCC. In contrast, the highway, which sees heavy trucks and high-speed traffic, would require a more robust solution like reinforced concrete.

Management of Cracking

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Relies on expansion, contraction, and construction joints to manage cracking

Detailed Explanation

The joints in PCC serve a vital function by accommodating the changes in volume that occur due to temperature fluctuations. Expansion joints allow for the concrete to expand in hot weather, while contraction joints let it shrink in cooler weather. Construction joints are installed where one batch of concrete meets another, ensuring a strong bond between sections. This strategic placement and design of the joints helps minimize cracking, which can lead to structural issues over time.

Examples & Analogies

Consider a rubber band. When you stretch it, it expands, and when you let go, it contracts. Just like the rubber band needs space to change its shape without breaking, the concrete needs these joints to expand and contract naturally without cracking.

Key Concepts

-

No Reinforcement: PCC does not use any steel, ensuring cost-effective solutions for low-traffic applications.

-

Types of Joints: Expansion and contraction joints are crucial for managing stress and maintaining the integrity of the pavement.

Examples & Applications

Example of a PCC application is a suburban roadway with light traffic, where cost efficiency is vital, making PCC a sensible choice.

In areas subject to mild climatic variations, PCC can effectively resist the impacts of minor thermal expansion and shrinkage.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

PCC is solid, it's clear, without steel it holds its peer!

Stories

Imagine a town where PCC roads connect homes without heavy burdens, allowing easy travels and light loads.

Memory Tools

Pavement Joints: E.C.C. - Expansion, Contraction, Control.

Acronyms

PCC

Plain

Cost-effective

Construction for light traffic.

Flash Cards

Glossary

- Plain Cement Concrete Pavement (PCC)

A type of pavement constructed from cement concrete without steel reinforcement, suitable for light to medium traffic.

- Reinforcement

The use of materials, such as steel bars, to increase the tensile strength of concrete.

- Expansion Joint

A joint designed to absorb the expansion and contraction caused by temperature changes.

- Contraction Joint

A joint used to control the cracking of concrete due to shrinkage.

- Construction Joint

A joint that is created when new concrete is placed against previously laid concrete.

Reference links

Supplementary resources to enhance your learning experience.