Subgrade and Sub-base Preparation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Subgrade Preparation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are discussing the subgrade, which forms the foundation of our pavement. Can anyone tell me why subgrade preparation is critical?

I think it’s important because it needs to support the weight of the pavement.

Exactly! The subgrade needs to be compacted to 95% of Modified Proctor Density to provide a strong support. Remember, if the subgrade isn't well-prepared, it can lead to cracks and failures in the pavement. Let's remember it with the acronym 'STRENGTH' - Stability, Thorough Compaction, Resistance to Settlement, Essential Drainage, Necessary for durability, Good material quality, High-performance standards.

What happens if there’s organic material in the subgrade?

Good question! Organic materials can weaken the subgrade and lead to settlement. It’s crucial to clear any organic matter before compaction.

Role of the Sub-base

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about the sub-base. Can someone explain what materials are typically used for the sub-base?

I believe granular material or lean concrete is used.

Correct! The sub-base acts as a working platform and a medium for load transfer. Remember that it should be 100 mm to 150 mm thick, and it helps distribute loads from the pavement. Can anyone think of why a proper sub-base is advantageous?

It might prevent crack propagation in the pavement?

Exactly! A well-prepared sub-base reduces stress on the subgrade and improves the overall durability of the pavement. Let’s use the mnemonic 'B.L.O.C.K.' for the sub-base functions: Base Layer, Load distribution, Optimal thickness, Construction platform, and Keeps moisture away.

Summarizing Subgrade and Sub-base Preparation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To summarize, both subgrade and sub-base are vital in ensuring a strong pavement structure. Subgrade needs to be compacted and free of organic material, while the sub-base should be of the correct material and thickness for effective load transfer. What are the main takeaways?

Subgrade must be compacted to 95% and kept free from organic matter.

Sub-base should be made from granular materials and must be thick enough to support loads!

Great! Remember, together they ensure the pavement remains durable and functional over time.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Subgrade preparation involves achieving adequate compaction and drainage of the foundation soil, while the sub-base serves as a stable load transfer medium. Both play critical roles in supporting the pavement and preventing structural failures.

Detailed

Subgrade and Sub-base Preparation

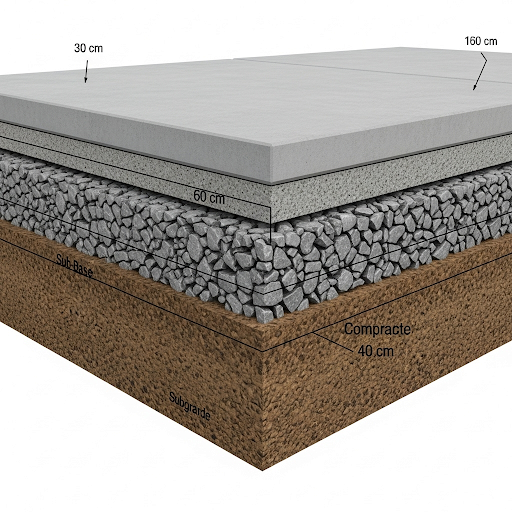

Proper preparation of the subgrade and sub-base is essential for the longevity and performance of cement concrete pavements. The subgrade must be sufficiently compacted to at least 95% of Modified Proctor Density, ensuring a stable foundation. It should also be well-drained and free from organic materials to reduce the risk of settlement or other issues in the pavement structure.

The sub-base, often composed of granular materials or lean concrete, typically has a thickness of 100mm to 150mm. It plays a vital role as a working platform for construction and as a load transfer layer that helps distribute traffic loads to the subgrade. Both components are crucial for sustaining the structural integrity of rigid pavements, underscoring their significance in ensuring durability and service life.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Subgrade Preparation

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

16.4.1 Subgrade

• Properly compacted to 95% of Modified Proctor Density

• Should be well-drained and free from organic material

Detailed Explanation

The subgrade is the foundation layer beneath the pavement. For a strong and durable pavement, the subgrade must be properly compacted to a density of 95% of the Modified Proctor Density, which means it has to be tightly packed down to ensure stability. Additionally, it must be well-drained; if water accumulates, it can weaken the subgrade and lead to pavement failure. Lastly, organic materials like roots or decaying plants can also weaken the subgrade and should be removed.

Examples & Analogies

Think of the subgrade as the foundation of a house. Just as a house needs a solid foundation to prevent it from settling or cracking, a pavement needs a well-prepared subgrade. For example, if you build a sandcastle on wet sand, it will likely collapse; similarly, if the subgrade is not solid and dry, the pavement on top will crack and break.

Role of Sub-base in Pavement Construction

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

16.4.2 Sub-base

• Often made from granular material or lean concrete

• Thickness: 100 mm to 150 mm

• Acts as a working platform and load transfer medium

Detailed Explanation

The sub-base is the layer placed directly above the subgrade and below the concrete pavement. It can be made from granular materials (like gravel) or lean concrete and typically has a thickness of 100 mm to 150 mm. The primary role of the sub-base is to provide a stable working platform for the construction work and to evenly transfer loads from the pavement to the subgrade below. This helps in distributing the weight of traffic, thus minimizing stress on the underlying subgrade.

Examples & Analogies

You can think of the sub-base like a cushion under a mattress. Just as a good mattress requires a solid base to support it and provide comfort, a concrete pavement needs a well-constructed sub-base to absorb and distribute the weight of vehicles, enhancing its durability and performance.

Key Concepts

-

Subgrade Preparation: Ensuring proper compaction and drainage.

-

Sub-base Role: Serving as a load transfer medium and working platform.

Examples & Applications

A construction site where subgrades are improperly compacted can lead to pavement cracking within a year due to insufficient support.

Using a lean concrete sub-base can enhance load distribution, especially in areas with heavy traffic.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For good pavement that won't crack,

Stories

Once, in a construction area, a lazy crew didn’t prepare the subgrade well, resulting in a cracked pavement. Years later, they learned that a solid subgrade ensures longevity, much like a well-built house.

Memory Tools

For subgrade remember: C.D.R.O. - Compaction, Drainage, Remove Organics.

Acronyms

S.T.R.O.N.G. for Sub-base

Support

Thickness

Resistance

Overall stability

Necessary support

Good construction.

Flash Cards

Glossary

- Subgrade

The layer of soil or rock that serves as the foundation for a pavement structure.

- Modified Proctor Density

A measure of soil compaction used to determine its maximum potential density.

- Subbase

A layer of material placed between the subgrade and the pavement, providing support and load distribution.

Reference links

Supplementary resources to enhance your learning experience.