Load Transfer Devices

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Load Transfer Devices

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are discussing load transfer devices in cement concrete pavements. Can anyone tell me why load transfer is important in pavements?

Is it to help distribute the load evenly across the pavement?

Exactly, Student_1! Load transfer is vital for ensuring the pavement remains stable under varying loads. We particularly use dowel bars and tie bars for this purpose.

What do dowel bars do specifically?

Dowel bars are placed at expansion and contraction joints. They allow for slab movement due to temperature changes while transferring loads between the slabs.

And tie bars?

Great question, Student_3! Tie bars are used to hold together adjacent slabs at longitudinal joints, ensuring that loads are well-distributed and the pavement sections do not separate.

So, without these devices, would the pavement crack more easily?

Yes, that's correct. Without proper load transfer devices, the risk of cracking and pavement failure increases significantly. Remember: Dowel bars for slab movement, and tie bars for maintaining slab continuity!

Applications of Load Transfer Devices

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss the applications of load transfer devices in real-world scenarios. Can anyone think of where we might see them?

On highways?

Absolutely! Highways and major roads often use these devices to counteract heavy traffic loads and improve durability.

Do they help with anything related to weather changes?

Yes! They are especially crucial in areas with temperature fluctuations, as they allow slabs to expand or contract without compromising structural integrity.

What happens if they’re not installed properly?

Good question, Student_3! Incorrect installation can lead to uneven load distribution, resulting in cracks and potentially costly repairs. Remember: proper alignment and spacing of dowel and tie bars are key!

What about maintenance? Do they require any special attention?

Typically, load transfer devices are low maintenance, but their condition should be monitored during overall pavement assessments to ensure functionality.

Key Takeaways about Load Transfer Devices

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To conclude today’s topic, let’s recap what we’ve learned about load transfer devices. Who can summarize what dowel bars do?

Dowel bars help transfer loads between slabs while allowing for movement.

Correct! And what about tie bars?

They keep the slabs together at longitudinal joints and help distribute the loads.

Exactly right! Remember, both are crucial for preventing cracks and ensuring the longevity of concrete pavements. Can anyone explain why they are vital in different weather conditions?

They accommodate thermal expansion and contraction!

Great job! Always remember the role of these devices: without them, we risk compromising the pavement's strength and stability. Keep these points in mind for future discussions!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

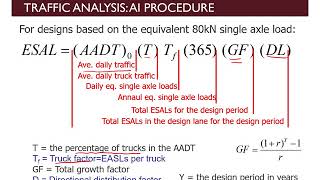

Load transfer devices, including dowel bars for expansion and contraction joints and tie bars for longitudinal joints, play a crucial role in ensuring stability and load distribution in cement concrete pavements. This section emphasizes their importance and application.

Detailed

Load Transfer Devices

Load transfer devices are essential components in the construction of cement concrete pavements. They are integral for maintaining the structural integrity of the pavement by facilitating effective load transfer across joints. Two primary types of load transfer devices are used:

- Dowel Bars: Used predominantly in expansion and contraction joints, dowel bars help in transferring loads between adjacent concrete slabs. They allow horizontal movement due to temperature variations while maintaining alignment and load distribution.

- Tie Bars: These are employed in longitudinal joints and are crucial for holding two pavement sections together. Tie bars prevent separation and help distribute loads, enhancing the pavement's overall structural capacity.

The use of these devices ensures durability and longevity of concrete pavements, especially under heavy traffic conditions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Dowel Bars

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Dowel Bars: For expansion and contraction joints

Detailed Explanation

Dowel bars are cylindrical rods, typically made of steel, which are placed in the concrete at expansion and contraction joints. Their primary function is to provide load transfer between the adjacent concrete slabs. When one slab moves due to temperature changes or traffic loads, the dowel bars help transfer the load to the adjacent slab, maintaining structural integrity and preventing misalignment or uneven settling.

Examples & Analogies

Imagine two books resting on a table that can slide slightly apart. If you place a pencil between the books, when one book moves, the pencil helps to guide and keep the second book aligned. Similarly, dowel bars help keep concrete slabs aligned while allowing necessary movement.

Tie Bars

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Tie Bars: For longitudinal joints

Detailed Explanation

Tie bars are steel bars used at longitudinal joints to provide additional support between adjacent concrete slabs. Unlike dowel bars, which allow for some movement, tie bars are designed to hold the slabs together, preventing them from separating and helping to evenly distribute loads. This is particularly important in areas subjected to heavy traffic, where maintaining the slab's integrity is essential.

Examples & Analogies

Think of a bridge where the planks need to stay together firmly while still allowing some flexibility for movement. If you use straps to hold the planks close together, it prevents them from moving apart, similar to how tie bars work to keep concrete slabs from separating.

Key Concepts

-

Dowel Bars: Essential for transferring loads in expansion and contraction joints while allowing slab movement.

-

Tie Bars: Used at longitudinal joints to prevent slab separation and improve load distribution.

Examples & Applications

In a busy urban highway, dowel bars are used at joints to accommodate traffic-induced stresses while preventing misalignment.

On a concrete street experiencing temperature variations, tie bars are placed to ensure slabs remain connected and load is evenly distributed.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Dowel bars keep the slabs in line, moving wide and transferring fine.

Stories

Imagine a roadway where different sections are like neighbors; dowel bars help them share loads without separating, creating harmony on the pavement.

Memory Tools

D for Dowel, T for Tie - both help slabs align and apply!

Acronyms

LT (Load Transfer)

for Dowel and T for Tie - think about the devices that stand by.

Flash Cards

Glossary

- Dowel Bars

Reinforcements used at expansion and contraction joints to transfer loads between adjacent concrete slabs.

- Tie Bars

Reinforcements used at longitudinal joints to hold adjacent slabs together and facilitate load distribution.

Reference links

Supplementary resources to enhance your learning experience.