Design of Cement Concrete Mix

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Nominal Mix vs. Design Mix

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start by understanding the two types of mixes. A nominal mix is often used for low-grade concrete, while a design mix is tailored for specific structural and strength needs.

So, is the nominal mix just a simple ratio like 1:2:4?

Yes! Exactly! It's a straightforward proportion. Now, can anyone tell me why we might choose the design mix instead?

Is it because it can provide the needed strength for heavier loads?

Correct! The design mix takes into account the target strength as well. Remember the acronym SAND? It stands for Strength, Aggregate type, Nominal and Design mix. This will help you remember!

Target Strength and Water-Cement Ratio

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's dive deeper into target strength. Can someone tell me what we do to calculate it?

Do we just find the characteristic compressive strength and add a safety margin?

Exactly! This ensures our concrete performs well under load. What about the water-cement ratio? Why is that important, Student_4?

It helps to achieve the right strength and durability!

Very well! Keeping the ratio between 0.4 and 0.5 is standard for strength. Remember, if it’s too high, it can weaken the concrete!

Workability and Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's switch gears to workability. What test do we use to measure it?

The slump test!

Right! What should the slump values be for pavements?

20 to 40 mm, if I remember correctly.

Spot on! And what about durability? Why do we need to consider its factors?

To ensure the concrete can withstand harsh weather and traffic conditions.

Excellent! Remember the acronym DURA? It stands for Durability, Use, Resistance, and Abrasion; tools to ensure our mix lasts long.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The design of a cement concrete mix involves choosing between nominal and design mixes, understanding target strength calculations, determining the water-cement ratio, and ensuring adequate workability and durability to cater to the intended applications. This section highlights critical parameters essential for achieving high-performance concrete pavements.

Detailed

Design of Cement Concrete Mix

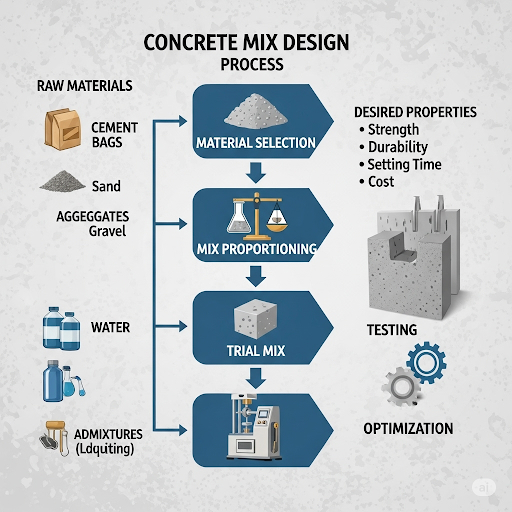

In the construction of cement concrete pavements, the design of cement concrete mix plays a crucial role in determining durability, strength, and overall performance. There are two main types of mixes employed: nominal mix and design mix.

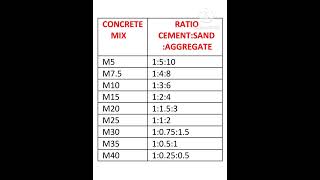

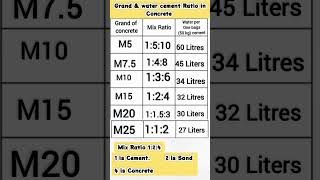

- Nominal Mix: Typically used for low-grade concrete, this approach utilizes a simple proportioning method (e.g., 1:2:4 refers to a mix of cement, sand, and coarse aggregate) and is suitable for less demanding applications.

- Design Mix: In contrast, design mixes involve a detailed process based on structural design requirements and target strength. This approach ensures that the concrete achieves specified performance standards under diverse conditions.

Key Elements in Mix Design:

- Target Strength: The characteristic compressive strength is calculated, and a margin is added to account for quality control.

- Water-Cement Ratio: A critical parameter affecting both strength and durability, it's typically maintained between 0.4 to 0.5, ensuring adequate hydration of cement.

- Workability: Evaluated using the slump test, where the recommended slump values for pavements are between 20 and 40 mm, allowing for ease of placement and compaction.

- Durability Considerations: The concrete mix must also be designed to resist abrasion, sulphate attack, and freeze-thaw cycles, especially in heavily trafficked and extreme climates.

The insights offered in this section are vital for the successful implementation and sustainability of concrete pavements.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Nominal Mix vs. Design Mix

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Nominal mix for low-grade concrete (e.g., 1:2:4)

• Design mix based on structural design and strength requirements

Detailed Explanation

In concrete mix design, there are two main approaches: nominal mix and design mix. The nominal mix is used for simpler applications and is a predetermined ratio of ingredients, such as a 1:2:4 ratio, which refers to the proportions of cement, sand, and aggregate. On the other hand, design mix is more sophisticated. It is tailored to meet specific structural requirements and strength needs, taking into account various environmental factors and loads the concrete will sustain.

Examples & Analogies

Think of it like a recipe for a cake. A nominal mix is like a basic recipe you follow without much thought, while a design mix is akin to a gourmet cake where every ingredient is measured specifically to achieve the perfect taste and texture based on the cake's purpose.

Target Strength

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Achieved by calculating characteristic compressive strength and adding a margin for quality control

Detailed Explanation

Target strength in concrete design refers to the desired compressive strength that the concrete must achieve to perform well under loads. This is calculated based on the characteristic compressive strength, which is generally determined by testing samples. Additionally, a safety margin is added to ensure that even if some variations occur in the material properties or mixing process, the concrete will still perform satisfactorily.

Examples & Analogies

Imagine you're training for a race. You might aim to run it in 10 minutes, but knowing that there could be factors like tiredness on the day of the race, you train to get it done in 9 minutes. That extra minute serves as your margin for ensuring you meet your goal.

Water-Cement Ratio

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Critical for strength and durability

• Typical range: 0.4 to 0.5

Detailed Explanation

The water-cement ratio is the ratio of the mass of water to the mass of cement used in a concrete mix. This ratio is crucial because it influences the strength and durability of the hardened concrete. A lower ratio leads to stronger concrete but might make it less workable, while a higher ratio can make the concrete easier to work with but weaker. The typical range of 0.4 to 0.5 is recommended to achieve a balance between workability and strength.

Examples & Analogies

Think of making a smoothie. If you add too much water, the flavor gets diluted and the consistency becomes too runny, but if you don’t add enough liquid, you can’t blend it properly. Similarly, you need just the right amount of water for concrete to have the perfect mix of strength and workability.

Workability

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Determined using slump test

• Slump values: 20–40 mm for pavements

Detailed Explanation

Workability refers to how easily a fresh concrete mix can be mixed, placed, and finished without causing segregation or excessive bleeding. It is usually measured using the slump test, where a cone-shaped mold is filled with the concrete mix and then removed, leaving a 'slump' measurement. For concrete used in pavements, an ideal slump value typically ranges from 20 to 40 mm, which indicates a good consistency while ensuring it's not too wet.

Examples & Analogies

Consider mixing a thick batter versus a thin one to make a pancake. If the batter is too thick (low workability), it’s hard to spread, but if it’s too thin (high workability), it won’t hold its shape. Just like with pancake batter, concrete needs the right texture to ensure it can be laid smoothly and will set correctly.

Durability Considerations

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Resistance to abrasion, sulphate attack, and freeze-thaw cycles

Detailed Explanation

Durability in concrete refers to its ability to withstand various environmental conditions and maintain its mechanical properties over time. Key factors include resistance to abrasion (wear due to friction), sulphate attack (damage from exposure to sulphate ions), and the freeze-thaw cycle (the expansion and contraction that occurs when water freezes inside the concrete). Incorporating the right materials and mix design can enhance these resistance properties.

Examples & Analogies

Think of a pair of shoes. If you buy a cheap pair, they might wear out quickly from daily walking (abrasion), get damaged if you walk through puddles in winter (freeze-thaw cycles), or fall apart if they come into contact with certain chemicals (sulphate attack). Durable shoes, much like well-designed concrete, will withstand these challenges much better.

Key Concepts

-

Nominal Mix: A simple concrete mix ratio suitable for low load requirements.

-

Design Mix: A scientifically determined concrete mix designed for specific strengths.

-

Target Strength: Compressive strength achieved with allowances for quality.

-

Water-Cement Ratio: The ratio fundamental to concrete's strength and durability.

-

Workability: Ease of handling and placement of concrete.

-

Durability: Concrete's ability to perform under adverse conditions without significant deterioration.

Examples & Applications

A nominal mix of 1:2:4 provides a basic strength suitable for sidewalk construction where carts and pedestrians mainly transit.

A design mix may be formulated as per the specific loading and environmental conditions for a highway subjected to heavy truck traffic.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For concrete that's tough and sound, mix it right and strength is found.

Stories

Imagine a builder working on a freeway. To ensure the pavement lasts, they carefully compute the mix, ensuring just enough water for durability and strong aggregate for structural integrity.

Memory Tools

Remember SAND: Strength, Aggregate, Nominal and Design mix for mixing concrete.

Acronyms

DURA

Durability

Use

Resistance

and Abrasion – key factors in concrete design.

Flash Cards

Glossary

- Nominal Mix

A concrete mix ratio used for low-grade concrete, typically represented as a simple ratio like 1:2:4.

- Design Mix

A tailored concrete mixture designed based on strength requirements and structural considerations.

- Target Strength

The specified compressive strength of concrete, calculated with a safety margin for quality assurance.

- WaterCement Ratio

The ratio of the weight of water to the weight of cement used in a concrete mix—critical for achieving desired strength and durability.

- Workability

The ease with which concrete can be mixed, placed, and finished, typically measured by slump tests.

- Durability

The ability of concrete to withstand weathering action, chemical attack, and abrasion while maintaining its desired performance.

- Slump Test

A test used to measure the workability of fresh concrete by observing the drop of a cone-shaped mold.

Reference links

Supplementary resources to enhance your learning experience.