Aggregates for Concrete

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Classification of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re going to explore the classification of aggregates. Can someone tell me the difference between fine and coarse aggregates?

Fine aggregates are smaller, right? Less than 4.75 mm?

Exactly! Fine aggregates include sand and fillers, while coarse aggregates are larger, greater than 4.75 mm. Can you give me an example of coarse aggregates?

Sure! Crushed stone and gravel are examples of coarse aggregates.

Great! Remember, the classification helps determine the role each type of aggregate plays in concrete. Rhyme needs to remember this: 'Fine is small, coarse is tall!'

Properties of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s discuss the properties of aggregates. What physical properties do you think are essential?

Size, grading, and moisture content are important!

Correct! Size and grading affect porosity and workability. What about mechanical properties?

Crushing value and impact value indicate strength and toughness.

Excellent! Knowing these properties helps in creating suitable concrete mixtures. Here’s a mnemonic: 'CISP'—Crushing, Impact, Size, Properties for quick recall!

Grading of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about grading of aggregates. What are the two types of grading mentioned?

Continuous grading and gap grading!

Right! Continuous grading ensures all sizes are represented, promoting dense packing. Can anyone explain gap grading?

It's when some sizes are missing, useful for architectural finishes.

Exactly! Also, keep in mind the Fineness Modulus for evaluating coarseness. For easy recall: 'FM is the balance of the grain'!

Testing of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Testing aggregates is crucial. What are some tests we perform?

Sieve analysis and crushing value tests!

Great! Sieve analysis helps determine particle size distribution. Can anyone tell me the limit for aggregate crushing value?

Less than 30% for concrete used in roads, right?

Correct! Always ensure compliance with standards. Here's a story: 'Imagine aggregates as soldiers; strong tests make strong concrete!'

Environmental Impact and Sustainability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss environmental impact. Why is using recycled aggregates beneficial?

They reduce waste and conserve natural resources!

Exactly! By recycling, we promote sustainability in construction. Can anyone list eco-friendly aggregates?

Manufactured sand and expanded clay, for instance.

Well done! Remembering to care for our planet while building is essential. Mnemonic: 'Reduce, Reuse, Rebuild!'.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section delves into the classification of aggregates based on various criteria such as size, origin, shape, and unit weight, while also examining their physical, mechanical, and thermal properties. Selected aggregates and their handling practices are crucial for optimal concrete performance.

Detailed

Aggregates for Concrete

Aggregates play a pivotal role in concrete technology, comprising 60-75% of the concrete's volume. Their selection and characteristics can significantly influence both fresh and hardened concrete properties such as workability, strength, and durability. This section provides an extensive overview of aggregates, categorizing them based on size, origin, shape, unit weight, and other properties.

Classification of Aggregates

Aggregates are classified into fine, coarse, and all-in aggregates based on their size, with fine aggregates being less than 4.75 mm and coarse aggregates greater than this size. They can also be natural, artificial, or recycled, with each type affecting the environmental impact and cost of concrete.

Properties of Aggregates

Key physical properties include size, shape, specific gravity, and moisture content. Mechanical properties encompass crushing resistance, impact toughness, and wear resistance. Thermal properties also play a part in the overall performance of concrete.

Grading and Combining of Aggregates

Proper grading is crucial for optimizing concrete mixes, and methods for combining aggregates include trial and error and mathematical formulations. Testing aggregates for quality assures compliance with industry standards, promoting structural integrity.

Role of Aggregates

Aggregates contribute to strength, workability, durability, and cost-effectiveness in concrete. Understanding their characteristics is essential to mitigate issues such as alkali-silica reaction and the presence of deleterious materials.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Aggregates

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Aggregates form the bulk of concrete volume—nearly 60–75%—and hence significantly influence the properties of both fresh and hardened concrete. They not only provide dimensional stability and durability but also contribute to the economy of concrete. The selection, grading, shape, and texture of aggregates directly impact workability, strength, and long-term performance. Therefore, understanding the classification, properties, testing methods, and role of aggregates is crucial in Concrete Technology.

Detailed Explanation

This chunk introduces aggregates as a critical component of concrete, making up a large portion of its volume (60-75%). Understanding aggregates is important because they influence both the fresh (when mixed) and hardened (after curing) properties of concrete. Key aspects such as how aggregates are selected, their grading (size distribution), shape, and surface texture directly affect how well the concrete works (workability), its strength (how much weight it can bear), and its long-term durability (how well it stands up to time and environmental factors).

Examples & Analogies

Think of aggregates like the ingredients in a recipe. Just as the right combination of flour, sugar, and eggs affects the final taste and texture of a cake, the selection and characteristics of aggregates define the quality and performance of concrete.

Classification of Aggregates

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Aggregates are broadly classified based on size, origin, shape, and specific gravity.

Detailed Explanation

Aggregates can be categorized into several types depending on their characteristics. The main classifications include:

- Size: This divides aggregates into fine (less than 4.75 mm) and coarse (greater than 4.75 mm) aggregates, each serving different functions in the concrete mix.

- Origin: Addresses whether aggregates are natural (from the earth), artificial (man-made), or recycled (from previous concrete).

- Shape: Differentiates aggregates by their geometric form which influences how they pack together in the concrete mix.

- Specific Gravity: A measure of density which helps determine the type of aggregate suitable for specific applications.

Examples & Analogies

Imagine organizing your toys. You might sort them by their size (small or large), what they're made of (plastic or metal), their shape (round or square), or how heavy they are (light or heavy). Similarly, engineers classify aggregates to understand better how each type will behave when combined to form concrete.

Properties of Aggregates

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The performance of aggregates in concrete depends on several physical and chemical properties.

Detailed Explanation

Aggregates have specific properties that affect concrete performance:

- Physical Properties: Include size, shape, specific gravity, and moisture content. These factors determine how aggregates will interact with cement paste and how workable the concrete will be.

- Mechanical Properties: Focus on how aggregates withstand stress and strain, such as their crushing strength and toughness.

- Thermal Properties: Relate to how aggregates respond to temperature changes and thermal conductivity, which impacts the heat resistance of concrete.

Examples & Analogies

Consider a sponge and a rock. The sponge (lightweight aggregate) absorbs water easily and can be used in insulation, while the rock (normal-weight aggregate) is heavy and provides strength in construction. This illustrates how different properties of aggregates determine their applications in concrete.

Grading of Aggregates

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Proper grading reduces voids and enhances strength, durability, and workability.

Detailed Explanation

Grading of aggregates involves classifying particles based on size to ensure a well-distributed mix. Good grading means fewer voids, which leads to improved bond strength in concrete. Fine aggregates are categorized into zones based on their particle sizes, and continuous grading ensures all sizes are present, enhancing packing density.

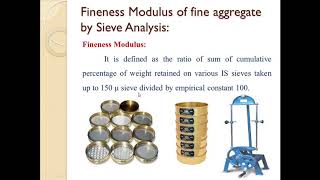

- Fineness Modulus (FM): A numerical value indicating the coarseness of an aggregate mix. Understanding the gradation helps in achieving the desired concrete performance.

Examples & Analogies

Imagine filling a jar with pebbles: if you only use large pebbles, there will be spaces between them where sand could fit, but if you add smaller stones and sand, the jar fills up more completely. Similarly, grading aggregates so that they range from fine to coarse allows concrete to be denser and stronger.

Testing of Aggregates

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Aggregates must be tested to ensure quality and compliance with standards.

Detailed Explanation

Testing aggregates is crucial to ensure they meet standards for use in concrete. Tests include:

- Sieve Analysis: Determines the size distribution of aggregates.

- Specific Gravity and Water Absorption: These tests help in mix design by indicating how much water the aggregates will hold or need.

- Crushing and Impact Values: Measure the aggregates' resistance to breaking under stress. Regular testing helps maintain the quality needed for structural integrity in concrete applications.

Examples & Analogies

Just like a quality check in a factory ensures that each product meets certain standards before making it to the store, testing aggregates confirms their performance characteristics before they are used to make concrete.

Role of Aggregates in Concrete

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Aggregates influence not just the strength and workability of concrete, but also critical performance parameters like permeability, shrinkage, and resistance to aggressive environments.

Detailed Explanation

Aggregates play a multifaceted role in concrete:

- Strength: Coarse aggregates provide the necessary strength and stiffness, allowing the concrete to bear loads.

- Workability: Fine aggregates help in achieving a workable mix that is easy to place and finish.

- Durability: Well-graded and sound aggregates improve the concrete's lifespan and performance over time.

- Economy: Aggregates are often cheaper than cement and can help lower overall costs in concrete production.

Examples & Analogies

Think of a car: the body (aggregates) holds it together and gives it strength, while the wheels (fine aggregates) help it move smoothly. Just like each part is essential for the car’s performance, aggregates are crucial for concrete's properties and functionality.

Key Concepts

-

Classification of Aggregates: Aggregates can be classified based on size, origin, shape, and density.

-

Properties of Aggregates: Physical and mechanical properties, including size, specific gravity, and resistance to wear.

-

Grading: Grading affects the allocation of spaces within concrete, influencing properties like strength and durability.

-

Alkali-Aggregate Reaction: A potentially damaging reaction that can affect the lifespan of concrete.

-

Sustainability: The use of recycled aggregates promotes sustainability and resource conservation.

Examples & Applications

Fine aggregates such as natural sand fill gaps in coarse aggregates, providing a strong and workable mix.

Recycled aggregates from demolished concrete may be used for non-structural applications like pavement.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For aggregates fine or coarse, mixed together, they source.

Stories

Once upon a time, in the world of concrete, aggregates teamed up to create solid foundations. The fine sands and coarse gravels worked harmoniously, proving that teamwork makes the dream work!

Memory Tools

To remember the properties of aggregates, think 'SPSM' for Size, Porosity, Strength, and Moisture.

Acronyms

Use the acronym 'C.G.N' to remember the types of aggregates

Coarse

Graded

Natural.

Flash Cards

Glossary

- Aggregates

Materials such as sand, gravel, and crushed stone that are combined with cement and water to make concrete.

- Fine Aggregates

Aggregates that pass through a 4.75 mm sieve, typically including sand.

- Coarse Aggregates

Aggregates larger than 4.75 mm, providing strength and stability.

- Grading

The particle size distribution of aggregates, influencing workability and strength.

- Fineness Modulus

An empirical figure to describe the coarseness of aggregates based on percentage retained on sieves.

- AlkaliAggregate Reaction

A chemical reaction between certain aggregates and alkaline cement leading to expansion and cracking.

Reference links

Supplementary resources to enhance your learning experience.