Classification of Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Classification Based on Size

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll begin by exploring the classification of aggregates based on size. Can anyone tell me the difference between fine and coarse aggregates?

Fine aggregates are smaller, right? They fill gaps between larger pieces.

Correct! Fine aggregates are particles smaller than 4.75 mm, including examples like natural sand and crushed stone sand. What about coarse aggregates?

Coarse aggregates are larger than 4.75 mm, like gravel or crushed stone.

Exactly! Coarse aggregates contribute to compressive strength but may also affect workability. Remember, we categorize aggregates by size primarily to understand their function in concrete.

So, what would you use fine aggregates for then?

Great question! Fine aggregates are essential to fill voids between coarse aggregates, ensuring a more uniform concrete mix. Let’s summarize: fine aggregates = <4.75 mm and coarse aggregates = >4.75 mm.

Classification Based on Origin

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we discuss the origin of aggregates. Who can tell me what natural aggregates are?

Natural aggregates come from places like rivers and quarries.

Exactly! They’re vital for concrete applications. Now, what about artificial aggregates?

They’re made from manufactured materials, like crushed bricks or slag.

Correct! And finally, let’s discuss recycled aggregates. Why are they significant?

They help in sustainability by using materials from demolished structures!

Exactly! Recycled aggregates promote sustainability and are becoming increasingly utilized. To recap: natural aggregates come from natural sources, artificial ones are manufactured, and recycled aggregates come from previous concrete.

Classification Based on Shape

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s explore the classification based on shape. How do you think the shape of aggregates influences concrete?

I guess rounded aggregates would be easier to work with?

Exactly! Rounded aggregates have a low surface area, which provides high workability but lower bond strength. What about angular aggregates?

They provide better strength due to their interlocking but might reduce workability, right?

You've got it! High interlock means better strength but decreased ease of mixing. Remember, for high-strength concrete, avoid flaky and elongated aggregates as they compromise workability.

So, we should use a mix of shapes to achieve the best properties in concrete?

Very good! Mixing shapes can balance workability and strength. Our key takeaway: round = higher workability, angular = better strength!

Classification Based on Unit Weight

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss aggregates based on unit weight. Who can tell me about normal weight?

Normal weight aggregates have a density of 1520 to 1680 kg/m³.

Great! Can anyone name a common normal weight aggregate?

Crushed stone and gravel are good examples.

Exactly! What about lightweight aggregates?

They are less than 1120 kg/m³ and used for insulation.

Correct! And heavyweight aggregates?

Those are used for radiation shielding, right?

Yes! Barytes and hematite are examples. Key takeaway: Normal weight aggregates provide strength, lightweight aggregates offer insulation, and heavyweight are for shielding!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Aggregates are crucial components of concrete, comprising 60-75% of its volume. This section details their classification into fine and coarse aggregates based on size, their natural or artificial origins, shape characteristics, and various weight classifications. Understanding these classifications is integral to concrete technology as they directly affect the material's workability, strength, and durability.

Detailed

Classification of Aggregates

Aggregates are fundamental in concrete as they represent a significant portion of its volume (60-75%). This section elaborates on the classification of aggregates based on different criteria:

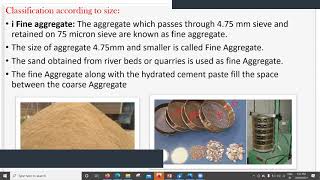

1. Based on Size

- Fine Aggregates: Less than 4.75 mm; they fill voids between coarse aggregates and include natural sand and crushed stone sand.

- Coarse Aggregates: Greater than 4.75 mm; they contribute to strength and stability and include various sizes like 10 mm, 20 mm, and 40 mm.

- All-in Aggregates: A mixture of fine and coarse aggregates used when grading precision isn't critical.

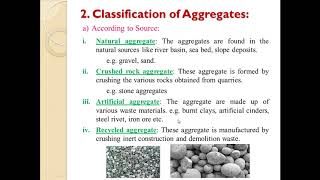

2. Based on Origin

- Natural Aggregates: Sourced from natural deposits (e.g., river gravel).

- Artificial Aggregates: Man-made materials (e.g., crushed bricks, sintered fly ash).

- Recycled Aggregates: From construction waste, promoting sustainable practices.

3. Based on Shape

- Rounded Aggregates: Easy to work with but may have lower bond strengths.

- Angular Aggregates: Provide better strength but may decrease workability due to higher interlocking.

- Flaky and Elongated Aggregates: Can adversely affect strength and workability, especially in high-strength concrete.

4. Based on Unit Weight

- Normal Weight: Density between 1520 and 1680 kg/m³; includes common materials like crushed stone.

- Lightweight Aggregates: Less than 1120 kg/m³, used in insulation or lightweight concrete.

- Heavyweight Aggregates: More than 2100 kg/m³, used for radiation shielding concrete.

Understanding these classifications helps in selecting the right type of aggregate for various concrete applications, ensuring the desired properties are achieved.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Aggregate Classification

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Aggregates are broadly classified based on size, origin, shape, and specific gravity.

Detailed Explanation

This classification scheme groups aggregates into categories that help understand their characteristics and applications. The classification is crucial because the properties of aggregates can significantly influence the performance and durability of concrete. Knowing these different categories can help engineers choose the right type based on the specific requirements of a construction project.

Examples & Analogies

Think of classifying aggregates like sorting fruits in a market; some may be sorted by size (small berries vs. large apples), others by where they come from (local farm vs. imported). This helps shoppers find the best fruit for their needs, just as it helps engineers select the right aggregate for concrete.

Classification Based on Size

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.1.1 Based on Size

- Fine Aggregates:

- Size: Less than 4.75 mm

- Examples: Natural sand, crushed stone sand, crushed gravel sand

- Passes through 4.75 mm IS sieve and is retained on 75 μm sieve

- Used to fill voids between coarse aggregates

- Coarse Aggregates:

- Size: Greater than 4.75 mm

- Common sizes: 10 mm, 20 mm, 40 mm

- Examples: Crushed stone, gravel, boulders

- Provide compressive strength and dimensional stability

- All-in Aggregates:

- Mixture of both fine and coarse aggregates

- Used where grading is not very strict.

Detailed Explanation

Aggregates can be classified based on size into fine aggregates (less than 4.75 mm), coarse aggregates (greater than 4.75 mm), and all-in aggregates (which contain both fine and coarse). Fine aggregates are generally used to fill the gaps between larger particles, making the concrete denser. Coarse aggregates provide the bulk of the concrete and significant strength. All-in aggregates can be useful when strict grading criteria are not required, simplifying the construction process.

Examples & Analogies

Imagine building a sandcastle. The fine aggregates, like beach sand, fill in the small crevices, ensuring a smooth surface, while the coarse aggregates, like small pebbles, form the structure's strength and form.

Classification Based on Origin

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.1.2 Based on Origin

- Natural Aggregates:

- Obtained from natural sources like river beds, pits, and quarries

- Examples: River gravel, natural sand

- Artificial Aggregates:

- By-products or manufactured materials

- Examples: Crushed bricks, blast furnace slag, sintered fly ash

- Recycled Aggregates:

- Sourced from demolished concrete structures

- Promotes sustainability in construction.

Detailed Explanation

Aggregates are also classified by their origin into natural, artificial, and recycled. Natural aggregates are sourced directly from nature and are the most commonly used. Artificial aggregates are man-made and can be beneficial for specific applications, such as in reducing weight or adding special properties to concrete. Recycled aggregates, produced from old concrete, support environmental sustainability by reducing waste and conserving resources.

Examples & Analogies

Think of natural aggregates as fresh vegetables from a farmer's market, while artificial aggregates are like processed foods that still provide nutrition but in different forms. Recycled aggregates are like leftovers creatively repurposed into new dishes, showing how old can become useful again.

Classification Based on Shape

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.1.3 Based on Shape

- Rounded Aggregates:

- Natural river gravels

- Low surface area, high workability, lower bond strength

- Angular Aggregates:

- Crushed rock

- High surface area and interlock; better strength and less workability

- Flaky Aggregates:

- Thickness is less than 0.6 times the mean dimension

- Reduce workability and strength

- Elongated Aggregates:

- Length is more than 1.8 times the mean dimension

- Similar effects as flaky particles

- Flaky and Elongated Aggregates:

- Not preferred in high-strength concrete.

Detailed Explanation

The shape of aggregates impacts their performance in concrete. Rounded aggregates, like those found in riverbeds, facilitate easier mixing and workability. Angular aggregates, however, provide better strength due to their interlocking nature but can be more challenging to work with. Flaky and elongated aggregates are discouraged in high-strength applications as they can negatively affect workability and the strength of the concrete mix.

Examples & Analogies

Imagine trying to stack different shapes of building blocks. Rounded blocks slide off each other easily, while angular blocks fit snugly but require more effort to position correctly. Similarly, the shape of aggregates affects how well they fit together in concrete.

Classification Based on Unit Weight

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.1.4 Based on Unit Weight

- Normal Weight Aggregates:

- Density: 1520 – 1680 kg/m³

- Examples: Crushed stone, gravel

- Lightweight Aggregates:

- Density: < 1120 kg/m³

- Used for insulation or structural lightweight concrete

- Examples: Pumice, expanded shale, vermiculite

- Heavyweight Aggregates:

- Density: > 2100 kg/m³

- Used in radiation shielding concrete

- Examples: Barytes, hematite, magnetite.

Detailed Explanation

Aggregates can also be categorized based on their unit weight. Normal weight aggregates form the most common type used in concrete due to their balance of density and strength. Lightweight aggregates are used when insulation properties or reduced weight are important, such as in roof structures. Conversely, heavyweight aggregates are used for specialized applications where radiation shielding is needed, like in nuclear facilities.

Examples & Analogies

Think of the differences like types of vehicles: a regular car (normal weight) is great for everyday travel, a lightweight car (like a Smart car) is nimble and fuel-efficient, while a heavyweight vehicle (like a tank) is built for specific high-demand situations that require extra strength and shielding.

Key Concepts

-

Fine Aggregates: Particles that are less than 4.75 mm in size.

-

Coarse Aggregates: Particles that are greater than 4.75 mm in size.

-

Natural Aggregates: Aggregates obtained from natural sources.

-

Artificial Aggregates: Manufactured aggregates, often derived from industrial by-products.

-

Recycled Aggregates: Aggregates sourced from construction waste.

-

Aggregate Shape: Influences strength and workability in concrete.

-

Lightweight Aggregates: Used for insulation, with density less than 1120 kg/m³.

-

Heavyweight Aggregates: Used in specialized applications, with density greater than 2100 kg/m³.

Examples & Applications

Fine aggregates like natural sand help improve the density of concrete by filling voids.

Coarse aggregates like crushed stone provide compressive strength, making concrete structurally stable.

Natural aggregates such as river gravel are commonly used for driveways and pathways.

Artificial aggregates like expanded clay are favored for lightweight concrete due to their lower density.

Recycled aggregates can be used in pavements, helping reduce waste from construction.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Fine aggregates small and neat, fill the gaps, can't be beat. Coarse aggregates mighty and bold, give the strength, make it hold!

Stories

In the kingdom of concrete, the wise wizard sought the perfect blend of aggregates to create a structure that would last. He chose the tiny fine aggregates to fill in the cracks, and the strong coarse aggregates to stand tall and proud, together creating a fortress that would endure the test of time.

Memory Tools

To remember types of aggregates, think of the acronym NARE: Natural, Artificial, Recycled, and Engineered (for clarity about manufacturing).

Acronyms

For Size Classification

= Fine < 4.75 mm; C = Coarse > 4.75 mm.

Flash Cards

Glossary

- Fine Aggregates

Aggregates with a size less than 4.75 mm; used to fill voids in concrete.

- Coarse Aggregates

Aggregates larger than 4.75 mm; they provide compressive strength.

- Natural Aggregates

Aggregates sourced from natural deposits like rivers, quarries, etc.

- Artificial Aggregates

Manufactured aggregates including materials such as crushed bricks.

- Recycled Aggregates

Aggregates sourced from the recycling of demolished concrete.

- Unit Weight

The weight of aggregates per unit volume, used for classification.

- Rounded Aggregates

Aggregates that are smooth and spherical, providing high workability.

- Angular Aggregates

Rough-edged aggregates that interlock, providing strength but lower workability.

- Lightweight Aggregates

Aggregates with a density of less than 1120 kg/m³, used for lightweight structures.

- Heavyweight Aggregates

Aggregates with a density greater than 2100 kg/m³, used for shielding against radiation.

Reference links

Supplementary resources to enhance your learning experience.