Based on Unit Weight

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Normal Weight Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing normal weight aggregates. These aggregates typically have a density ranging from 1520 to 1680 kg/m³. Can anyone give me examples?

Are crushed stone and gravel considered normal weight aggregates?

Exactly! Crushed stone and gravel are common examples. They provide strength and durability, which are essential for standard concrete applications.

Why is it important to know about the density of aggregates?

Great question! The density affects not just the strength but also the overall weight of concrete, which can influence design decisions in construction.

So would using too heavy aggregates be a problem?

Yes! While strength is crucial, if aggregates are too heavy, it can lead to structural challenges. Remember, the right balance is key!

In summary, normal weight aggregates provide the necessary strength for conventional concrete, with the density affecting both performance and design.

Exploring Lightweight Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's look at lightweight aggregates. These have a density of less than 1120 kg/m³. What do we think is their primary benefit?

I guess they are useful for reducing the weight of concrete structures?

Exactly! This reduction can significantly impact transportation costs and structural load. Common examples are pumice and expanded shale.

So, are they weaker than normal aggregates?

Not necessarily! While they may have lower strength, they are designed to perform well in specific applications like insulation or lightweight structural concrete.

To summarize, lightweight aggregates are excellent choices in projects aiming to decrease weight while providing thermal insulation properties.

Understanding Heavyweight Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's shift our focus to heavyweight aggregates, which have a density greater than 2100 kg/m³. Can someone tell me where we would use these?

They would be used in places where radiation shielding is necessary, right?

That's correct! Heavyweight aggregates like barytes and magnetite are crucial for radiation shielding in certain construction designs.

What are the implications of using heavyweight aggregates in concrete?

Using these aggregates increases the concrete's weight, thus requiring careful planning in terms of structural support and design. But the protection from radiation is well worth it in specific applications.

In conclusion, heavyweight aggregates are essential in specialized applications where additional density is required to combat radiation.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

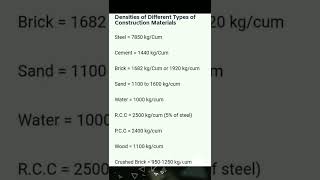

Aggregates can be classified based on unit weight into three main categories: Normal Weight Aggregates with densities between 1520-1680 kg/m³, Lightweight Aggregates that are less than 1120 kg/m³, and Heavyweight Aggregates that exceed 2100 kg/m³. Each type serves different construction purposes based on their density and properties.

Detailed

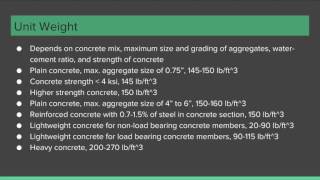

In this section, aggregates are classified primarily according to their unit weight, which plays a critical role in determining their applications in construction.

Types of Aggregates Based on Unit Weight

- Normal Weight Aggregates:

- Density: Ranges from 1520 – 1680 kg/m³.

- Examples: Crushed stone, gravel. They are commonly used in standard concrete mixes and provide good compressive strength and durability.

- Lightweight Aggregates:

- Density: Typically less than 1120 kg/m³.

- Uses: Ideal for insulation and lightweight structural concrete, which is advantageous for reducing the overall weight of structures while maintaining adequate strength.

- Examples: Pumice, expanded shale, and vermiculite.

- Heavyweight Aggregates:

- Density: Greater than 2100 kg/m³.

- Purpose: Utilized primarily in radiation shielding concrete, which is critical in environments that require protection from harmful radiations.

- Examples: Barytes, hematite, and magnetite.

Understanding the types of aggregates based on unit weight is essential for selecting appropriate materials for various concrete applications, enhancing structural integrity and performance.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Normal Weight Aggregates

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Normal Weight Aggregates

- Density: 1520 – 1680 kg/m³

- Examples: Crushed stone, gravel

Detailed Explanation

Normal weight aggregates have a density ranging from 1520 to 1680 kg/m³, which means they are considered standard weight materials in concrete. Examples include commonly used crushed stone and gravel. These types of aggregates provide good structural properties and are typically the first choice for most concrete applications.

Examples & Analogies

Think of normal weight aggregates like the bricks you use in building a house. Just as bricks give stability and form to a structure, normal weight aggregates help concrete achieve the necessary strength and durability for various constructions like sidewalks, buildings, and driveways.

Lightweight Aggregates

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Lightweight Aggregates

- Density: < 1120 kg/m³

- Used for insulation or structural lightweight concrete

- Examples: Pumice, expanded shale, vermiculite

Detailed Explanation

Lightweight aggregates have a density of less than 1120 kg/m³, making them significantly less heavy than normal aggregates. They are often used in applications that require lighter concrete, which can help reduce overall structural weight and improve insulation properties. Common lightweight aggregates include materials like pumice, expanded shale, and vermiculite.

Examples & Analogies

Imagine packing your travel bag. You choose lightweight materials like a thin jacket instead of a heavy one. Similarly, lightweight aggregates help reduce the weight of concrete while maintaining necessary structural integrity, making it easier to work with, especially in elevated constructions or insulated walls.

Heavyweight Aggregates

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Heavyweight Aggregates

- Density: > 2100 kg/m³

- Used in radiation shielding concrete

- Examples: Barytes, hematite, magnetite

Detailed Explanation

Heavyweight aggregates have a density greater than 2100 kg/m³, making them suitable for specific applications where resistance to radiation is required. These aggregates are often used in concrete that must shield against radiation, like in facilities handling radioactive materials. Examples include barytes, hematite, and magnetite, which all have high densities.

Examples & Analogies

Consider a superhero suit that protects the wearer from harmful elements. Just like that suit provides an extra layer of protection, heavyweight aggregates ensure that concrete not only provides structural support but also shields against harmful radiation, making it essential for buildings near medical or nuclear facilities.

Key Concepts

-

Normal Weight Aggregates: Aggregates typically having a density of 1520-1680 kg/m³, providing the strength necessary for standard concrete.

-

Lightweight Aggregates: Aggregates with a density less than 1120 kg/m³, useful for reducing weight and enhancing insulation in concrete.

-

Heavyweight Aggregates: Aggregates with a density exceeding 2100 kg/m³, necessary for specialized concrete applications like radiation shielding.

Examples & Applications

Normal weight aggregates include crushed stone and gravel, used in standard concrete applications for durability.

Lightweight aggregates like pumice and expanded shale are used in construction where insulation properties are crucial.

Heavyweight aggregates such as barytes and hematite are employed in environments requiring radiation shielding.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Lightweight aggregates, oh so light, save on weight, what a great sight!

Stories

Imagine a cold building that uses lightweight aggregates, allowing it to keep the warmth inside, while heavyweight aggregates build a fortress against radiation.

Memory Tools

For aggregates, remember N-L-H: Normal (normal weight), L (lightweight), H (heavyweight) to categorize by density range.

Acronyms

Remember 'N-L-H' for the three types of aggregates

for Normal

for Lightweight

for Heavyweight.

Flash Cards

Glossary

- Normal Weight Aggregates

Aggregates with a density ranging between 1520 and 1680 kg/m³, commonly used in conventional concrete applications.

- Lightweight Aggregates

Aggregates with a density of less than 1120 kg/m³, used for insulation and lightweight structural concrete.

- Heavyweight Aggregates

Aggregates with a density greater than 2100 kg/m³, used primarily in radiation shielding concrete.

Reference links

Supplementary resources to enhance your learning experience.