Grading of Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Grading Zones of Fine Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll learn about the grading of fine aggregates as per IS: 383. Fine aggregates are classified into four zones based on their particle sizes. Can anyone tell me what those zones are?

Are they Zone I, Zone II, Zone III, and Zone IV?

Exactly! Zone I is the coarsest, while Zone IV is the finest. Zone II is preferred for most concrete applications because it balances workability and strength.

Why is Zone II so popular?

Great question! The medium size helps minimize voids while providing good bond characteristics with cement. Remember: 'Zone II is the sweet spot for concrete!'

Continuous vs Gap Grading

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s differentiate between continuous grading and gap grading. Continuous grading means all sizes are present. What benefits do you think this provides?

It probably reduces voids and leads to better compaction, right?

Absolutely! Continuous grading enhances density. Now, gap grading has one or more sizes missing. Why might that be useful?

It can be used for specific architectural finishes!

Exactly! But remember, while gap grading can be aesthetically pleasing, it may compromise workability. So, which would you choose for structural concrete?

Continuous grading would be better for strength.

Understanding Fineness Modulus

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss the fineness modulus. What do you think it represents?

Is it a measure of aggregate coarseness?

Correct! The fineness modulus is calculated by taking the cumulative percentage retained on standard sieves and dividing by 100. Can anyone tell me typical values for sand and coarse aggregate?

Sand usually has a fineness modulus between 2.3 and 3.1, and coarse aggregates have a value of 6 to 7.

Excellent! Fineness modulus helps us understand how much cement paste is required for the mixture. Remember: 'A lower FM means finer material, affecting the water-cement ratio!'

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the importance of proper grading of aggregates in concrete technology, outlining the classifications of fine aggregates into grading zones, the comparison between continuous and gap grading, as well as the concept of fineness modulus. Understanding these concepts is key for achieving optimal concrete mix design and performance.

Detailed

Grading of Aggregates

Proper grading of aggregates is integral to achieving minimal voids and optimal performance in concrete mixtures. This section elaborates on:

Grading Zones (According to IS: 383)

Fine aggregates are classified into four distinct grading zones:

1. Zone I: Coarsest

2. Zone II: Medium (most commonly used)

3. Zone III: Moderately fine

4. Zone IV: Finest

It’s critical to note that Zone II sands are preferred for most concrete placements due to their balanced properties.

Gap Grading vs Continuous Grading

- Continuous Grading: This involves having all particle sizes present, resulting in dense packing and better performance.

- Gap Grading: This is characterized by missing one or more particle sizes, which may be useful for certain architectural finishes but can lead to poorer workability.

Fineness Modulus (FM)

Fineness modulus serves as an empirical figure indicating the coarseness or fineness of aggregates, calculated as the cumulative percentage of material retained on standard sieves divided by 100. Typical values range from 2.3 to 3.1 for sand and 6 to 7 for coarse aggregates.

Understanding and applying these grading principles is essential as they directly affect workability, strength, and durability in concrete.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Grading

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Proper grading reduces voids and enhances strength, durability, and workability.

Detailed Explanation

Grading of aggregates is crucial for optimizing concrete performance. Proper grading refers to the distribution of different particle sizes within the aggregate mix. A well-graded aggregate mix can fill voids more efficiently, meaning there are fewer gaps between particles. This reduction in voids leads to increased strength in the concrete, improves its durability, and enhances the ease of handling and placing the concrete (workability).

Examples & Analogies

Imagine packing a suitcase. If you only put large items in, there will be lots of empty spaces, making it less efficient. However, if you carefully select a mix of small and large items, you fill the spaces better and maximize your packing. Similarly, grading aggregates helps fill the concrete 'suitcase' effectively.

Grading Zones (As per IS: 383)

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fine aggregates are classified into 4 zones:

- Zone I: Coarsest

- Zone II: Medium

- Zone III: Moderately fine

- Zone IV: Finest

Note: Zone II sand is preferred for most concrete works.

Detailed Explanation

According to the IS: 383 standard, fine aggregates are divided into four distinct grading zones. Zone I is the coarsest, consisting of larger particles, while Zone IV is the finest, with smaller particles. Zone II is considered the ideal choice for most concrete applications due to its balanced particle size distribution. Using the appropriate zone ensures that the concrete maintains its integrity, strength, and workability.

Examples & Analogies

Think of choosing ingredients for a smoothie. If you pick all large fruits, it becomes chunky and hard to blend. If you choose very small, soft fruits, it might not have the right texture. Zone II is like picking the perfect mix of fruits that blend well together, ensuring a smooth and tasty result.

Gap Grading vs Continuous Grading

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Continuous Grading: All particle sizes present, results in dense packing.

- Gap Grading: One or more sizes missing, used in architectural finishes.

Detailed Explanation

Continuous grading involves having a full range of particle sizes present in the mix, leading to optimal packing and minimal voids. In contrast, gap grading is characterized by the absence of certain particle sizes, which can create a unique visual effect in architectural applications. This absence can also impact the overall strength and durability compared to fully graded mixes.

Examples & Analogies

Imagine filling a jar with marbles. If you use marbles of varying sizes (continuous grading), they fit neatly without gaps. But if you leave out some sizes (gap grading), your jar looks stylish but might not hold as much or be as sturdy. Similarly, different grading methods get different results in concrete performance.

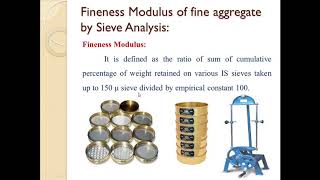

Fineness Modulus (FM)

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Empirical figure to describe aggregate coarseness

- FM = Cumulative % retained on standard sieves / 100

- Typical FM:

- Sand: 2.3–3.1

- Coarse Aggregate: 6–7

Detailed Explanation

Fineness Modulus (FM) is a numerical value that provides insight into the coarseness of aggregate materials. It is calculated by taking the cumulative percentage weight of the sample that is retained on standard sieves and dividing it by 100. A lower FM indicates finer aggregates, while a higher FM indicates coarser aggregates. This measurement helps engineers and technicians determine the appropriate aggregates for specific concrete mixes.

Examples & Analogies

Think of FM like measuring the coarseness of flour. If you have fine flour, it will have a low measurement, while coarse flour will have a higher one. By knowing the FM, you can decide which type of flour is best for your recipe – just like choosing aggregates for concrete based on required properties!

Key Concepts

-

Grading of Aggregates: A method to categorize aggregates based on size for optimal concrete mix.

-

Fineness Modulus: A calculated value that indicates aggregate coarseness.

-

Continuous Grading: Incorporates all particle sizes, enhancing workability and strength.

-

Gap Grading: Missing one or more sizes, used for specific aesthetic applications.

Examples & Applications

Zone II sand is commonly used in concrete as it provides a good balance of workability and strength.

Continuous grading is ideal for structural applications because it occupies less void space.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Grading is cool, it sets the rule, for sand that's needed, it aids the tool.

Stories

Imagine a builder in a town deciding between smooth river sand or rough broken stone; he finds that balanced sand (Zone II) gives him both strength and easy work.

Memory Tools

Remember: C-Gap for Continuous Grading and Gaps in Gap Grading.

Acronyms

FM for Fineness Modulus - Fines Matter!

Flash Cards

Glossary

- Grading Zones

Categories that define the particle size distribution of fine aggregates as per standards.

- Continuous Grading

A grading method where all particle sizes are present in the mix.

- Gap Grading

A grading method where one or more particle sizes are missing from the mix.

- Fineness Modulus

An empirical value that indicates the coarseness or fineness of aggregates.

Reference links

Supplementary resources to enhance your learning experience.