Testing of Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Sieve Analysis

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss sieve analysis, a fundamental test in aggregate evaluation. This test helps determine the particle size distribution of aggregates. Why do you think this is important?

Maybe it helps to know how much of each size is present?

Exactly! Knowing the size distribution allows us to calculate the Fineness Modulus, which affects workability and strength. Can anyone tell me what Fineness Modulus represents?

It's a measure of how coarse or fine the aggregate is?

Precisely! A higher Fineness Modulus indicates coarser aggregates. This influences how much paste is needed for the mix. Remember, aggregates take up a lot of volume in concrete—about 60 to 75%. Let's keep that in mind!

Specific Gravity and Water Absorption

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we'll look at specific gravity and water absorption. Why do we need to measure these properties?

Maybe to know how much water to add to the mix?

Correct! Knowing how much water aggregates can absorb is crucial for determining the water-cement ratio. If aggregates absorb too much water, it can weaken the concrete. Can anyone tell me the difference between apparent specific gravity and bulk specific gravity?

Apparent specific gravity includes the volume of voids, while bulk is just the volume of the solid part.

Well done! Understanding these terms helps in ensuring proper mix designs, which is fundamental for achieving desired concrete performance.

Aggregate Crushing and Impact Value

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s focus on aggregate crushing value and impact value. These tests reflect the strength of aggregates. What do you think would happen to concrete if we used aggregates with too high a crushing value?

It would probably break easily?

Exactly! The crushing value needs to be below 30% for aggregates used in roads to guarantee durability. Why is the impact value also important?

It tells us how they resist sudden forces, right?

Perfect! The impact value gives us insights into how tough the aggregates are, especially for pavement applications. Always remember: Toughness and strength go hand in hand!

Los Angeles Abrasion Test and Soundness Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss the Los Angeles Abrasion Test. Can someone explain why we test for wear resistance?

To ensure the aggregates can withstand heavy traffic?

Absolutely! A limit of less than 30% abrasion loss is desirable for high-quality concrete. Now, what about the soundness test?

Isn't that to check if the aggregates resist weathering?

Exactly! We want to make sure aggregates can withstand freeze-thaw cycles and chemical attacks. Quality aggregates ensure long-lasting concrete!

Alkali-Aggregate Reactivity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, we have alkali-aggregate reactivity. Can someone explain what happens when certain aggregates react with alkalis in cement?

They can expand and crack the concrete over time?

Right! This expansion can lead to structural issues. To mitigate this, what strategies can we apply?

We can use pozzolans or low-alkali cement!

Exactly! Understanding potential reactions is critical in preventing them. Great job, everyone! Continuous testing of aggregates maintains concrete quality.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

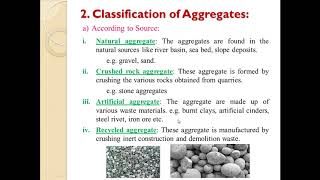

Aggregates are vital in concrete technology, and testing them is essential to ensure their performance meets standards. The section outlines key aggregate tests like sieve analysis, specific gravity, and various durability tests to gauge aggregate quality.

Detailed

Testing of Aggregates

Aggregates constitute a significant portion of concrete and play a crucial role in determining its overall performance. To ensure their suitability for use in concrete mixes, several tests are performed. This section highlights various tests, including: 1) Sieve Analysis (IS: 2386 Part I) - This test determines the particle size distribution, which is essential for calculating the Fineness Modulus, thereby ensuring that the aggregates are of appropriate size for optimal concrete performance. 2) Specific Gravity and Water Absorption (IS: 2386 Part III) - These tests are critical for mix design, as they provide insights into the materials' density and their ability to absorb water, influencing the water-cement ratio. 3) Aggregate Crushing Value (IS: 2386 Part IV) - This test measures the resistance of aggregates to crushing under compressive load, with specified limits for different concrete applications. 4) Aggregate Impact Value (IS: 2386 Part IV) - It assesses the toughness of aggregates and has strict limits based on their intended use. 5) Los Angeles Abrasion Test (IS: 2386 Part IV) - It evaluates wear resistance, essential for the durability of concrete, especially in pavements. 6) Soundness Test - This test assesses the aggregates’ resistance to weathering, which is crucial for longevity in concrete structures. 7) Alkali-Aggregate Reactivity (AAR) - Understanding this reactivity is essential to prevent expansive reactions in concrete caused by certain aggregates. By conducting these tests, concrete technologists can ensure that the aggregates meet the required standards for the intended concrete application, thus enhancing the durability and strength of the final product.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Sieve Analysis

Chapter 1 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.5.1 Sieve Analysis (IS: 2386 Part I)

- Determines particle size distribution

- Helps in computing Fineness Modulus

Detailed Explanation

Sieve analysis is a method used to determine the size distribution of particles in aggregates. This involves passing the aggregates through a series of sieves with different mesh sizes. The goal is to find out how much of the material falls into various size categories. This is crucial because the size distribution affects the concrete's overall properties, including its strength and workability. By analyzing the results, engineers can compute the Fineness Modulus, which helps in assessing how fine or coarse the aggregate mix is.

Examples & Analogies

Think of sieve analysis like sorting a jar of mixed nuts. If you had a series of plates with different hole sizes and poured the mixture through them, smaller nuts would fall through the holes while larger ones remain on top. This way, you can separate the nuts into categories based on size, helping you decide how to use them in recipes, similar to how engineers determine how to best combine aggregates for concrete.

Specific Gravity and Water Absorption

Chapter 2 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.5.2 Specific Gravity and Water Absorption (IS: 2386 Part III)

- Helps in concrete mix design

- Specific Gravity Types:

- Apparent Specific Gravity

- Bulk Specific Gravity (oven-dry and SSD basis)

Detailed Explanation

Specific gravity measures the density of aggregates compared to water, allowing engineers to understand how much of the aggregate contributes to the concrete's weight and stability. There are different types of specific gravity measurements: 'Apparent Specific Gravity' considers only the solid volume, while 'Bulk Specific Gravity' includes the volume of voids in the aggregates, measured both when the aggregates are dry and when they are saturated at the surface dry (SSD) condition. Understanding these values helps in balancing the concrete mix and ensuring optimal performance.

Examples & Analogies

Imagine you're making a fruit salad and you need to know how much fruit you have compared to how full your bowl is. The specific gravity measurements are like weighing each type of fruit (whole or cut) to figure out how to achieve a perfect balance in your salad. Similarly, concrete needs the right balance of aggregate’s density to achieve the desired structural performance.

Aggregate Crushing Value

Chapter 3 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.5.3 Aggregate Crushing Value (IS: 2386 Part IV)

- Measures resistance to crushing under compression

- Limit: < 30% for concrete used in roads, < 45% otherwise

Detailed Explanation

The Aggregate Crushing Value (ACV) test assesses how well an aggregate can withstand heavy loads. During the test, aggregates are subjected to a compressive load, and the percentage of crushed material is measured. A lower ACV value indicates higher strength and durability, making the aggregate suitable for use in roads and structures. Specifically, an ACV of less than 30% is considered ideal for road construction; otherwise, if it's higher than 30%, the material may be unsuitable.

Examples & Analogies

Think of ACV like testing how many books you can stack before they crush each other under pressure. If you stack only a few heavy books and they bend or break, it shows that your stack isn't stable, just like aggregates with a high crushing value aren't strong enough for construction.

Aggregate Impact Value

Chapter 4 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.5.4 Aggregate Impact Value (IS: 2386 Part IV)

- Indicates toughness

- Limit: < 45% for pavement, < 30% for wearing surfaces

Detailed Explanation

The Aggregate Impact Value (AIV) test measures the aggregate's ability to resist sudden shock or impact. By dropping a weight on the aggregates, the test determines how much material breaks under this impact. The lower the impact value, the tougher the aggregate, which is crucial for materials used in roads and surfaces that experience frequent stresses. For example, pavement aggregates should have an AIV of less than 45%, while aggregates for surfaces that wear need even tougher limits at below 30%.

Examples & Analogies

Imagine you're evaluating how tough a ball is by throwing it against a wall and seeing if it breaks or bounces back. If it can withstand multiple hits, it’s like having a low impact value in aggregates which ensures they can handle the stresses of traffic and weather.

Los Angeles Abrasion Test

Chapter 5 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.5.5 Los Angeles Abrasion Test (IS: 2386 Part IV)

- Measures wear resistance

- Limit: < 30% for high-quality concrete

Detailed Explanation

The Los Angeles Abrasion test evaluates the durability of aggregate against wear and tear, simulating the conditions aggregates would face in actual use. Through a rotating drum test, aggregates are subjected to friction and impact with steel balls, with the resulting wear or loss measured. A threshold of less than 30% loss indicates a high-quality aggregate suitable for use in concrete that requires excellent durability.

Examples & Analogies

Think of this test like putting a new pair of shoes through a durability test by walking miles on rough terrain. If they wear out quickly, they’re not suitable for such conditions; similarly, aggregates that show high wear in this test won't hold up in construction.

Soundness Test

Chapter 6 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.5.6 Soundness Test

- Assesses resistance to weathering (freeze-thaw or chemical attack)

- Carried out using sodium/magnesium sulfate solutions

Detailed Explanation

The Soundness Test determines how well aggregates can resist weathering effects, particularly freeze-thaw cycles or chemical actions. This is critical because aggregates that fail under these conditions can lead to structural failures in concrete over time. The test uses saturated sodium or magnesium sulfate solutions to see if aggregates expand or disintegrate when subjected to such conditions.

Examples & Analogies

Consider how a fruit might react to extreme cold—some freeze and lose their texture, while others can resist changing conditions. Similarly, aggregates that sound soft under the soundness test may fail in concrete during harsh weather if they can't withstand freeze-thaw cycles.

Alkali-Aggregate Reactivity

Chapter 7 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.5.7 Alkali-Aggregate Reactivity (AAR)

- Some aggregates react with alkalis in cement causing expansion and cracking

- Mitigation: Use of pozzolans, low-alkali cement

Detailed Explanation

Alkali-Aggregate Reactivity (AAR) is a chemical reaction that can occur between certain reactive silicas in aggregates and the alkali components in cement. This reaction forms a gel that expands when wet, leading to cracking and distress in concrete structures over time. To prevent this issue, construction practices may include using low-alkali cements or incorporating pozzolanic materials that mitigate the reaction.

Examples & Analogies

Think of AAR like a sponge in water; when soaked, it expands and takes up more space. If your sponge is mixed with other materials that make it expand too much, it could burst. In concrete, if reactive aggregates expand too much, they can compromise the structural integrity over time.

Key Concepts

-

Sieve Analysis: Determines particle size distribution of aggregates.

-

Specific Gravity: Indicates the density of aggregates affecting concrete mix.

-

Aggregate Crushing Value: Measures the resistance of aggregates to crushing.

-

Aggregate Impact Value: Measures toughness of aggregates.

-

Durability Tests: Assess wear resistance and soundness of aggregates.

-

Alkali-Aggregate Reactivity: A key factor in preventing concrete damage.

Examples & Applications

An aggregate with a crushing value below 30% is suitable for road construction, ensuring structural integrity.

A high specific gravity value indicates dense aggregates capable of providing better strength in concrete.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When aggregates crush or wear away, testing's the key to strength and stay.

Stories

Imagine a builder selecting the best aggregates for a road. He must conduct tests to ensure they won't crack or crumble, keeping the road safe and durable for years to come.

Memory Tools

Remember 'S.C.A.L.A' for testing aggregates: Sieve, Crushing Value, Absorption, Los Angeles Test, Alkali-Reactivity.

Acronyms

Use the acronym 'SAVE' to remember

Specific gravity

Aggregate values

Viscosity impact

Evaluation of soundness.

Flash Cards

Glossary

- Sieve Analysis

A test to determine the particle size distribution of aggregates.

- Specific Gravity

The ratio of the density of aggregate to the density of water.

- Aggregate Crushing Value

The measure of resistance to crushing under compressive load.

- Aggregate Impact Value

An indication of the toughness or resistance of aggregate to sudden impacts.

- Los Angeles Abrasion Test

A test that measures the durability and wear resistance of aggregates.

- Soundness Test

A test to evaluate the resistance of aggregates to weathering.

- AlkaliAggregate Reactivity

A chemical reaction between reactive silica in aggregates and alkalis in cement, causing expansion.

Reference links

Supplementary resources to enhance your learning experience.