Trial and Error Method

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to the Trial and Error Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re going to discuss the Trial and Error Method for combining aggregates in concrete. Can anyone tell me why this method is important?

I think it helps in finding the right mix of aggregates to create strong concrete?

Exactly! The right mix improves workability and strength. The method involves plotting gradation curves of different aggregates and adjusting their proportions accordingly. This way, we can target specific performance metrics.

How do we know what the desired grading is?

Great question! The desired grading typically depends on project specifications, including structural requirements and environmental conditions.

So, it’s like mixing different colors to get the perfect shade?

Precisely, you can think of it that way! We adjust the ratios until we achieve the right balance in concrete.

Implementing the Trial and Error Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss how we actually implement the Trial and Error Method. What do you think is the first step?

I guess we need to prepare samples of different aggregates?

Correct! We start by selecting aggregates from various sources and sizes. Next, we plot their gradation curves.

What do we do after that?

Once we have our curves, we begin combining the aggregates in different proportions. We observe how each mixture performs in terms of workability and strength.

Is it all about testing physical properties?

Yes, observing the mixing behavior and testing the resulting concrete properties help us refine our mixture until it meets our requirements.

Evaluating Results from the Trial and Error Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

After you've conducted the Trial and Error Method, how do you evaluate the success of your aggregate selection?

We should test the concrete for strength and workability, right?

Absolutely! You also want to compare the gradation curves of your tested samples. If they align with the desired curve, we can confidently use that mix.

What if none of the combinations work?

In that case, we might need to revisit and adjust the range of aggregates we’re testing. It's all part of the process!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The Trial and Error Method is crucial in selecting the right proportions of aggregates to obtain optimum concrete properties. This method involves plotting gradation curves of various aggregate sizes and adjusting their proportions based on desired outcomes.

Detailed

Detailed Summary

The Trial and Error Method is an essential approach in concrete mix design, focusing on blending different size fractions of aggregates to achieve a specific grading curve that meets project requirements. This method requires the visual representation of aggregate gradation curves, allowing engineers to assess how different proportions affect the overall grading. By systematically adjusting the ratios of fine and coarse aggregates, practitioners can meet desired specifications regarding workability, strength, and durability of concrete.

The significance of the Trial and Error Method lies in its practical application in various scenarios, including optimizing aggregate combinations for unique environmental conditions or project specifications. This method enables a flexible and empirical approach to design concrete that meets all structural and performance criteria effectively.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding the Trial and Error Method

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

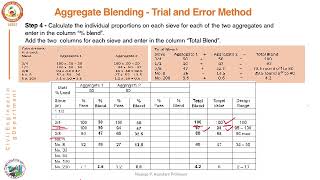

Gradation curve of different size fractions plotted and combined proportionately to match desired grading.

Detailed Explanation

The Trial and Error Method involves plotting a gradation curve, which visually represents the size distribution of aggregate fractions. By combining these different size fractions in various proportions, engineers can adjust the mix to achieve the desired grading for the concrete. This approach relies on comparing the actual aggregate gradation to an ideal gradation curve, which shows the optimal distribution of sizes for achieving the best performance of concrete in terms of strength and workability.

Examples & Analogies

Think of making a fruit salad. You might start with apples, oranges, and bananas in certain proportions. If you taste it and feel it's too apple-heavy, you might add more bananas or oranges. In the same way, engineers adjust the proportions of different aggregate sizes until the mixture feels just right for the specific concrete application. Just like you would adjust based on taste, engineers adjust based on performance characteristics.

Application in Concrete Mix Design

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

This method is particularly useful when aiming to optimize the concrete mix for specific requirements such as strength, durability, and workability.

Detailed Explanation

In concrete mix design, specific properties such as strength, durability, and workability are critical for the end product's success. The Trial and Error Method allows for flexibility in these mixes since aggregate sizes can significantly affect the concrete's final characteristics. By experimenting with different combinations, engineers can identify which mix yields the best balance of these properties for the intended application, ensuring that the concrete can meet construction demands and performance specifications.

Examples & Analogies

Imagine trying to create the perfect cake. You might need to experiment with different amounts of flour, sugar, and eggs to get a fluffy and delicious outcome. Similarly, engineers use the Trial and Error Method to find the right combination of aggregate sizes that lead to strong and workable concrete, much like trialing different cake recipes until they find the best one.

Key Concepts

-

Trial and Error Method: A practical approach for optimizing aggregate proportions in concrete mixes.

-

Gradation Curve: A tool for visualizing and determining the particle size distribution of aggregates.

Examples & Applications

For instance, if a project requires high workability, aggregates might be combined with a higher percentage of finer materials to achieve the desired flow.

An example of the Trial and Error Method in action could be trying different ratios of crushed stone to gravel to see which combination provides the needed strength and durability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In the mix of stone and sand, trial and error goes hand in hand.

Stories

Imagine a chef mixing ingredients; they try a pinch of salt and a dash of spice until the perfect flavor is found, just like mixing aggregates for concrete.

Memory Tools

To remember the steps: Plot, Combine, Test (PCT) for successful grades.

Acronyms

GAP - Gradation, Adjust, Perfect (remember GAP during your Trial and Error!).

Flash Cards

Glossary

- Gradation Curve

A graphical representation showing the distribution of particle sizes within a concrete mix.

- Proportions

The specific ratios of different aggregates used in a concrete mix.

Reference links

Supplementary resources to enhance your learning experience.