Properties of Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Physical Properties of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start with the physical properties of aggregates. Can anyone tell me why size and grading are important?

I think proper grading helps in minimizing voids, but I'm not sure how it works.

Exactly! Proper grading ensures that the gaps between larger aggregates are filled with smaller aggregates, reducing voids and optimizing the amount of cement paste needed. This leads to stronger concrete. Remember the phrase: 'Grading Good, Concrete Strong!'

What about shape and texture? How do they affect workability?

Great question! The shape can vary from rounded to angular aggregates. Rounded aggregates generally have lower surface area, increasing workability, while angular aggregates might provide better strength due to their interlocking nature. Think of it like puzzle pieces—the more they fit together, the stronger the structure!

What about specific gravity? Why is it significant?

Specific gravity gives us an idea of the density of the aggregate, which helps in mix design. Higher specific gravity often means better performance. We summarize it as: 'Heavy and Strong, Always Belongs!'

How does porosity affect the concrete?

High porosity increases water absorption, affecting the water-cement ratio critical for achieving desired strength. Remember: 'Porous Promises Poor Performance!'

In summary, physical properties like size, grading, shape, and porosity significantly influence concrete quality. Their effects can dictate the concrete’s strength and durability.

Mechanical Properties of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s look at mechanical properties. What do you think crushing value tells us?

It must indicate how strong the aggregate is under pressure, right?

Correct! The crushing value measures the resistance of aggregates to crushing under compressive loads. A lower value indicates higher strength. Memorize: 'Low Crushing Value, Strong and Stable!'

What does impact value measure?

Impact value assesses the toughness of aggregates, indicating resistance to sudden impacts. It’s particularly important for road surfaces where sudden loads occur. Think of it as: 'Tough Aggregate, Tough Concrete!'

How do the abrasion values matter?

Good point! Abrasion value reflects wear resistance. It's pivotal for surfaces exposed to friction, like roadways. Remember: 'Endurance Counts on the Ground!'

Are flakiness and elongation indices related to shape?

Precisely! Those indices measure the shape and can negatively impact the strength and compaction of concrete. Shape matters greatly. In fact, consider: 'Fit Matters for Firmness!'

In summary, the mechanical properties of aggregates—crushing value, impact value, abrasion value, and shape indices—are key to ensuring concrete can withstand various stresses.

Thermal Properties of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss thermal properties. Why is thermal expansion significant when considering concrete?

Is it about how concrete reacts to heat? Like expanding and contracting?

Exactly! Thermal expansion can impact the integrity of concrete under temperature changes. A stable thermal property equals better durability. Keep in mind: 'Balance in Heat, Stability Can’t be Beat!'

And what about conductivity? How does that factor in?

Good observation! Thermal conductivity measures how well heat is transferred through concrete, influencing insulation properties. Think: 'Conduct Good, Insulate Strong!'

So, for thermal stability, what should we look for in aggregates?

We want aggregates with low thermal conductivity and manageable thermal expansion to maintain performance. To sum it up: 'Stable Heat = Strong Feet!'

Overall, understanding thermal properties helps ensure that concrete retains its strength and durability even in extreme temperatures.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Aggregates play a fundamental role in concrete, making up 60-75% of the volume. This section covers the key properties of aggregates, including physical, mechanical, and thermal characteristics, explaining how these influence the workability, strength, and durability of concrete.

Detailed

Properties of Aggregates

Aggregates constitute the majority of concrete volume, significantly influencing its properties. Understanding the various properties of aggregates—both physical and mechanical—is crucial for achieving desired concrete performance.

1. Physical Properties

- Size and Grading: Proper grading minimizes voids and optimizes paste requirement.

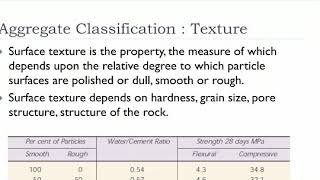

- Shape and Texture: Affects the workability and strength of concrete.

- Specific Gravity: Indicates the density of aggregates, which is essential in mix design.

- Bulk Density: Helps in evaluating how aggregates behave within the concrete mix.

- Porosity and Absorption: High porosity leads to increased water absorption, impacting the water-cement ratio.

- Moisture Content: Affects the effective water-cement ratio.

2. Mechanical Properties

- Crushing Value: Measures how aggregates resist crumbling under compressive loads.

- Impact Value: Measures toughness, indicating aggregates' resistance to sudden impacts.

- Abrasion Value: Assesses wear resistance, critical for surfaces like roads.

- Flakiness and Elongation Index: Indices that affect strength and overall compaction.

3. Thermal Properties

- Thermal Expansion: Important trait for maintaining the fire resistance of concrete structures.

- Conductivity: Affects the thermal insulation qualities of concrete.

Understanding these properties is key to selecting appropriate aggregates for specific concrete applications, ensuring optimal performance and longevity.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Physical Properties of Aggregates

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.2.1 Physical Properties

- Size and Grading: Proper grading ensures minimum voids and optimal paste requirement.

- Shape and Texture: Affects workability and strength.

- Specific Gravity: Indicates density of aggregates.

- Bulk Density: Indicates how aggregates will behave in the concrete mix.

- Porosity and Absorption: High porosity increases water absorption and affects water-cement ratio.

- Moisture Content: Impacts effective water-cement ratio.

Detailed Explanation

The physical properties of aggregates play a critical role in determining how they behave in concrete.

- Size and Grading: The size of aggregates affects the overall mixture. Proper grading (the distribution of different sizes) helps reduce empty spaces (voids) so that less paste (cement and water) is needed for binding.

- Shape and Texture: The way aggregates are shaped—smooth, rough, rounded, or angular—impacts how easily they can be mixed into the concrete and how strong the final concrete will be. Rough aggregates tend to bond better with cement.

- Specific Gravity: This indicates how heavy the aggregates are relative to their volume. A higher specific gravity typically suggests stronger aggregates.

- Bulk Density: This tells us how much aggregate can fit into a certain volume, affecting the concrete's overall density.

- Porosity and Absorption: Aggregates that are highly porous absorb more water, which can lead to discrepancies in the water-cement ratio during mixing.

- Moisture Content: The amount of water present in aggregates at the time of mixing affects the water-cement ratio, which is crucial for achieving desired strength in concrete.

Examples & Analogies

Imagine making a cake where the mix represents concrete and the ingredients represent aggregates. If you have too many lumps (voids) in your flour (aggregate size and grading), you’ll need more liquid (paste) to make it smooth. Similarly, if some of your ingredients are too wet (moisture content), you might end up with a soggy cake instead of a fluffy one!

Mechanical Properties of Aggregates

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.2.2 Mechanical Properties

- Crushing Value: Measures resistance to crushing under compressive load.

- Impact Value: Indicates toughness or resistance to sudden impact.

- Abrasion Value: Indicates wear resistance, important for road surfaces.

- Flakiness and Elongation Index: Shape indices that affect strength and compaction.

Detailed Explanation

Mechanical properties provide insight into how aggregates will perform under stress during use.

- Crushing Value: This tests how well aggregates can withstand crushing forces, an important factor for load-bearing concrete. A lower crushing value indicates a stronger material.

- Impact Value: This assesses the toughness of aggregates—the ability to withstand sudden forces or shocks, crucial for concrete in areas with high impact, like roads.

- Abrasion Value: This evaluates how resistant aggregates are to wear and tear when subjected to friction. High abrasion values are necessary for surfaces that experience heavy traffic.

- Flakiness and Elongation Index: These indices measure the shapes of the aggregates. Flaky or elongated aggregates can lead to weaker concrete, as they do not pack as efficiently, leaving more voids.

Examples & Analogies

Consider the difference between a solid rock and a piece of chalk. When you hit them (impact), the rock remains intact while the chalk breaks easily. Similarly, strong aggregates will contribute durability to concrete, just like solid rocks ensure a sturdy building when stacked together.

Thermal Properties of Aggregates

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.2.3 Thermal Properties

- Thermal Expansion: Important for fire resistance and thermal stability.

- Conductivity: Affects thermal insulation of concrete.

Detailed Explanation

The thermal properties of aggregates define how they respond to temperature changes, which is crucial for concrete's performance in various climates.

- Thermal Expansion: This refers to how much aggregates will expand when heated. Understanding this property is vital for structures exposed to high temperatures (like bridges) as significant expansion can lead to cracking.

- Conductivity: This describes how well heat travels through the aggregates. Low conductivity is beneficial for insulation, helping in energy-efficient buildings where maintaining interior temperatures is essential.

Examples & Analogies

Think of aggregates like a sweater and a cooling breeze. A good insulating sweater will keep you warm despite cold winds due to low conductivity, while poor-quality fabric will let the chill in. Similarly, the right aggregates can help keep buildings warm and energy-efficient!

Key Concepts

-

Size and Grading: Determines optimal mix design and workability.

-

Shape and Texture: Influences how aggregates bond with cement.

-

Porosity: Affects water absorption and strength.

-

Mechanical Properties: Key to ensuring aggregates can withstand various conditions.

Examples & Applications

Example of grading: Properly graded aggregate mixes reduce the amount of concrete needed, thereby lowering costs.

Example of shape: Rounded aggregates improve workability, while angular particles enhance strength.

Porosity example: Aggregates with lower porosity are preferred for structural applications to limit water absorption.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For strong concrete, keep them tight, Size and grading help it right!

Stories

Once there was a builder who learned that by properly grading his aggregates, he reduced costs and increased strength, enabling him to construct the tallest tower in the city.

Memory Tools

PICES - Porosity, Impact, Crushing, Elasticity, Strength - to remember key properties.

Acronyms

SCAMP - Size, Crushing, Absorption, Moisture, Properties - for aggregate properties.

Flash Cards

Glossary

- Specific Gravity

A measure of the density of aggregates compared to the density of water.

- Bulk Density

The mass of the aggregate divided by its volume, indicating how aggregates behave in a mix.

- Porosity

The ratio of void space in aggregates which affects water absorption.

- Absorption

The ability of aggregates to soak up water, impacting the water-cement ratio.

- Crushing Value

A test that determines the resistance of aggregates to crushing under load.

- Impact Value

A measure of the toughness or ability of aggregates to withstand sudden shock or impact.

- Abrasion Value

Indicates the wear resistance of aggregates in response to friction.

Reference links

Supplementary resources to enhance your learning experience.