Alkali-Aggregate Reactivity (AAR)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Alkali-Aggregate Reactivity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are discussing Alkali-Aggregate Reactivity, or AAR. It involves a chemical reaction between alkalis in cement and reactive aggregates, primarily silica in nature. This can lead to serious issues like cracking in concrete structures.

What causes these reactions to happen?

Great question! The reactions typically occur due to the presence of moisture. When reactive silica aggregates interact with alkalis while saturated with water, they produce a gel that expands over time.

Are all aggregates reactive, though?

No, not at all! Only certain types of aggregates containing high levels of reactive silica are of concern. This is known as the Alkali-Silica Reaction, or ASR.

What about other types of reactivity?

That's a good point! There’s also Alkali-Carbonate Reaction, which is less common and involves specific dolomitic rocks. It's essential to understand both types.

So, can these reactions be controlled?

Exactly! Preventive measures include using low-alkali cement and non-reactive aggregates to avoid the problem altogether. We can also use pozzolanic materials like fly ash to mitigate risks.

That sounds like a solid plan!

Let’s recap. AAR relates to the reaction between alkali in cement and reactive aggregates. To prevent it, we can use low-alkali cement and pozzolans. Always remember, moisture is key to these reactions!

Consequences of AAR

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's explore what happens when AAR occurs in concrete. What do you think could be the consequences?

I guess it would result in cracking.

Correct! Cracking and spalling are critical consequences of AAR. Expansion caused by the reaction can lead to significant distress in concrete.

Does that affect the strength of the concrete too?

Absolutely! Beyond aesthetic issues, AAR can severely reduce the concrete's load-carrying capacity, impacting structural integrity.

Wow, that sounds severe! Can the cracking be prevented?

One of the best preventive strategies is to control moisture ingress. Keeping the aggregates dry can significantly help reduce the likelihood of these reactions occurring.

So controlling moisture really is critical?

Exactly! To sum up, AAR can cause cracking, spalling, and loss of structural integrity in concrete. Preventing moisture ingress is crucial in mitigating these risks!

Mitigation Strategies for AAR

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to mitigation strategies for AAR. What do you think are some effective approaches?

Using low-alkali cement seems like a good idea?

Spot on! Low-alkali cement can significantly reduce the risk of AAR since it contains fewer alkalis that can react.

What else can we do apart from that?

Incorporating non-reactive aggregates is another critical strategy. Also, using pozzolanic materials can absorb some of the alkalis and mitigate potential reactions.

Does that really work?

Yes, it does! It’s a proven technique in many successful concrete projects. Finally, keeping moisture levels controlled will augment these strategies.

So it’s really about prevention?

Absolutely! To summarize, mitigating AAR can be done by using low-alkali cement, non-reactive aggregates, and controlling moisture. These strategies are essential for durable concrete.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section on Alkali-Aggregate Reactivity (AAR) highlights the potential for some aggregates to chemically react with the alkalis in cement. This reaction can result in the formation of expansive gels, causing severe cracking and deterioration of concrete structures. To mitigate these issues, techniques such as using pozzolanic materials and low-alkali cement are recommended.

Detailed

Alkali-Aggregate Reactivity (AAR)

Alkali-Aggregate Reactivity (AAR) is a significant concern in concrete technology, particularly in relation to the long-term durability of concrete structures. AAR involves a chemical reaction between the alkalis present in concrete (mainly from the cement) and reactive forms of silica found in certain aggregates. This interaction can lead to the formation of a gel that absorbs water, expands, and causes cracking within the concrete over time.

Key Points:

- Reactive Aggregates: Not all aggregates are prone to reactivity; typically, only those with high silica content are of concern.

- Alkali-Silica Reaction (ASR) is the most common type of AAR, requiring reactive silica, moisture, and alkalis for its occurrence.

- Alkali-Carbonate Reaction (ACR) is less common and involves specific dolomitic rock types.

- Consequences of AAR: The detrimental effects of AAR include:

- Cracking and spalling of concrete.

- Loss of durability and structural integrity.

- Reductions in load-carrying capacity.

- Preventive Measures: To mitigate AAR, several strategies can be employed:

- Use of low-alkali cement with sodium oxide equivalent content below 0.6%.

- Incorporation of non-reactive aggregates.

- Adding pozzolanic materials like fly ash, slag, or silica fume, which consume alkalis and inhibit reactive processes.

- Controlling moisture ingress to minimize expansive harm.

Understanding AAR is fundamental for ensuring the longevity and safety of concrete constructions, especially when using potentially reactive aggregates.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to AAR

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Some aggregates react with alkalis in cement causing expansion and cracking.

Detailed Explanation

Alkali-Aggregate Reactivity (AAR) is a phenomenon that occurs when certain types of aggregates, specifically those containing reactive forms of silica, interact with alkalis (sodium and potassium hydroxides) found in cement. This reaction can lead to a chemical process that causes the aggregates to expand over time, resulting in significant structural issues such as cracking and deterioration in concrete.

Examples & Analogies

Imagine a sponge that absorbs water. If the sponge continues to soak up water, it expands; similarly, when reactive aggregates absorb moisture and produce a gel in the presence of alkalis, they swell and can cause the concrete structure to crack, much like how an over-saturated sponge can break apart.

Mitigation Strategies

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Mitigation: Use of pozzolans, low-alkali cement.

Detailed Explanation

To prevent the damaging effects of AAR, it is essential to implement mitigation strategies. One effective method is the use of pozzolans, which are materials that react with lime in the presence of water to form compounds with cementing properties. These can counteract the alkali-silica reaction. Additionally, using low-alkali cement, which has a reduced amount of alkali content, can minimize the risk of AAR occurring. By combining these methods, concrete structures can be designed to withstand the adverse effects of aggregates that might otherwise lead to damage.

Examples & Analogies

Think of baking a cake: if you use too much baking soda (akin to alkalis in cement), your cake may rise too much and then collapse. By using less baking soda (low-alkali cement) or adding other ingredients that stabilize the cake (pozzolans), you can ensure a well-risen, stable, and delicious cake. Similar strategies help ensure that concrete remains strong and durable over time.

Key Concepts

-

Alkali-Silica Reaction (ASR): A reaction between alkalis and reactive silica leading to gel formation and expansion in concrete.

-

Mitigation Strategies: Use of low-alkali cement, non-reactive aggregates, and moisture control to prevent AAR.

Examples & Applications

In a highway construction project, low-alkali cement was used to prevent AAR in reactive aggregates found in the local quarry.

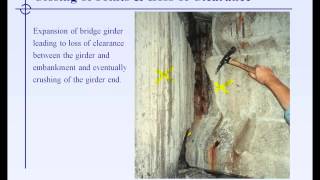

A bridge constructed with high-reactivity aggregates exhibited significant cracking over time, illustrating the effects of AAR.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To keep concrete intact and strong, use low alkalies all along!

Stories

In a small town, builders learned that using low-alkali cement saved their bridges from cracking due to reactivity with local aggregates.

Memory Tools

Remember 'CALM' for AAR prevention: Control moisture, Alkali-low cement, Low-reactive aggregates, Mitigation materials.

Acronyms

AAR

Aggressive Alkali Reaction—watch out for the cracks!

Flash Cards

Glossary

- AlkaliAggregate Reactivity (AAR)

A chemical reaction between alkalis in cement and reactive silica in aggregates leading to expansion and cracking.

- AlkaliSilica Reaction (ASR)

The most common type of AAR involving reactive silica that produces an expansive gel.

- AlkaliCarbonate Reaction (ACR)

A less common type of AAR affecting specific types of dolomitic aggregates.

- Pozzolanic Materials

Materials that, when mixed with cement, react with the calcium hydroxide to form compounds possessing cementitious properties.

- Moisture Ingress

The process of water entering concrete, which can facilitate AAR.

Reference links

Supplementary resources to enhance your learning experience.