Based on Shape

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Overview of Aggregate Shapes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore how the shape of aggregates influences the properties of concrete. Can anyone tell me the four main types of aggregate shapes?

Is it rounded, angular, flaky, and elongated?

Exactly! Rounded aggregates are smooth and often come from river gravel. They offer high workability but lower bond strength. Why do you think that bond strength matters?

I think it’s important for the concrete to stick together and hold its shape.

Exactly! A lower bond strength can lead to less durable concrete. Let’s move on to angular aggregates. What makes these aggregates different?

They have a higher surface area and better interlocking.

Correct! The higher interlock contributes to better strength but at the cost of workability. Remember: **AHS - Angular = Higher Strength**.

What about flaky and elongated aggregates? Are they the same?

Great question! They have different criteria for their dimensions, but both reduce workability and strength, which is why we avoid them in high-strength concrete.

To summarize: the shape affects workability and strength. Rounded gives high workability, angular yields strength, and flaky and elongated decrease both.

Implications of Aggregate Shapes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've discussed the different shapes, let's dive deeper into how they affect concrete performance. Student_1, can you remind us of what rounded aggregates do?

They improve workability a lot, but they don't bond well with cement.

Exactly! And that's crucial when we want durable concrete. What about angular aggregates, Student_2?

They have high interlock, so they’re stronger but harder to work with.

Right! The trade-off is significant. Now, for flaky and elongated aggregates: why do we usually avoid them in high-strength applications?

Because they can reduce the overall strength of the concrete.

Well said! Think of it as having a weak link in a strong chain. Let's create a mnemonic: **FLE - Flaky and Elongated = Fewer Strength**. Can anyone think of a situation where you might prefer rounded aggregates?

Maybe for sidewalks or areas where strength isn't the main concern?

Precisely! For structures where load-bearing strength is less of an issue, high workability is beneficial. Remember to consider these attributes when selecting aggregates for your concrete projects.

Classification and Usage

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

In our final session, let's review when we might choose each type of aggregate. Student_1, can you provide an example of where you’d use angular aggregates?

For something like a high-strength concrete application, right?

Correct! High-strength structures benefit from the interlock of angular aggregates. Student_2, what about rounded aggregates?

They would be great for driveways or pathways where workability is a priority.

Exactly! Now, would you say flaky and elongated aggregates have any use in concrete?

Maybe in non-structural applications or mixed with other shapes to balance.

Good insight! They can serve in scenarios where weight reduction is desired but care must be taken. Let’s remember: **Choose your aggregates like clothes: fit the job!** Remember to weigh both strength and workability!

To summarize today’s lessons: the choice of aggregates based on shape influences the durability and performance of our concrete mixes tremendously.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Aggregates used in concrete are categorized based on their shape into four types: rounded, angular, flaky, and elongated. Each type has unique properties that influence concrete's workability and strength, with specific implications for structural performance.

Detailed

Based on Shape

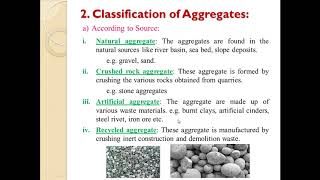

In concrete technology, the shape of aggregates can significantly affect the properties of the resulting concrete. Aggregates can be classified into different categories based on their geometrical shape:

- Rounded Aggregates: These are typically natural river gravels that exhibit a low surface area, leading to high workability in concrete mixes. However, they result in lower bond strength with cement paste.

- Angular Aggregates: Generally derived from crushed rock, these aggregates have a higher surface area and interlocking capacity. This feature enhances the strength of concrete but reduces workability, making it harder to work with.

- Flaky Aggregates: These are characterized by a thickness that is less than 0.6 times their mean dimension. Flaky aggregates can decrease the workability and overall strength of concrete mixes, making them less desirable.

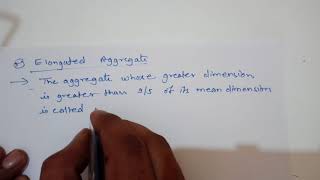

- Elongated Aggregates: Defined by their length being more than 1.8 times their mean dimension, elongated aggregates exhibit similar effects as flaky aggregates, impairing both workability and strength in concrete. The use of both flaky and elongated aggregates is generally not preferred in high-strength concrete applications.

Understanding these classifications is crucial as the choice of aggregate shape can have a major impact on the durability and performance of the concrete mix.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Rounded Aggregates

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Rounded Aggregates:

- Natural river gravels

- Low surface area, high workability, lower bond strength

Detailed Explanation

Rounded aggregates are typically found in river beds and are characterized by their smooth and rounded surfaces. The smooth texture leads to a lower surface area, which allows for easier mixing and improved workability when making concrete. However, this shape may result in a lower bond strength with cement compared to other shapes, meaning they may not hold as well when mixed with concrete.

Examples & Analogies

Think of rounded aggregates like marbles: they roll easily and can be moved around without much friction. This is similar to how rounded aggregates allow for easy placement in concrete, but just like marbles may not fit well together to form a solid structure, rounded aggregates can struggle to bond strongly with the cement.

Angular Aggregates

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Angular Aggregates:

- Crushed rock

- High surface area and interlock; better strength and less workability

Detailed Explanation

Angular aggregates are formed by crushing rocks into sharp, angular pieces. These sharp edges provide a high surface area that facilitates better interlocking between the aggregates. This interlocking enhances the strength of the concrete but can also lead to decreased workability. The increased friction from the angular shapes can make it more challenging to mix and pour the concrete evenly.

Examples & Analogies

Imagine trying to stack irregular-shaped puzzle pieces versus smooth balls. The puzzle pieces (angular aggregates) fit together more securely, providing strength, but they're harder to manage and fit into place (workability) compared to the smooth balls, which represent rounded aggregates.

Flaky Aggregates

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Flaky Aggregates:

- Thickness is less than 0.6 times the mean dimension

- Reduce workability and strength

Detailed Explanation

Flaky aggregates have a shape in which either the width or the length is significantly greater than the thickness. This results in a lower volume of aggregate in a given space, as their shape does not pack well. Consequently, flaky aggregates tend to reduce both the overall workability of the concrete and its compressive strength because they do not interlock as effectively as other shapes.

Examples & Analogies

Think of flaky aggregates like slices of bread: when you stack them, they don't fit together well like solid blocks would. This poor packing can lead to gaps in your concrete, just like loosely stacked slices could fall apart easily.

Elongated Aggregates

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Elongated Aggregates:

- Length is more than 1.8 times the mean dimension

- Similar effects as flaky particles

Detailed Explanation

Elongated aggregates are characterized by their long and narrow shape, where the length exceeds 1.8 times the other dimensions. Much like flaky aggregates, elongated aggregates can also lead to poor concrete strength and lower workability because they do not fit together compactly in the mixture. This shape can also create voids in the concrete mix, ultimately compromising the integrity of the cured concrete.

Examples & Analogies

Consider a box of crayons where some are long and thin (elongated aggregates). If you tried to fit them all into a small container, they wouldn't stack well with others of varying lengths, similar to how elongated aggregates can create issues in a concrete mixture.

Flaky and Elongated Aggregates

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Flaky and Elongated Aggregates:

- Not preferred in high-strength concrete

Detailed Explanation

Both flaky and elongated aggregates are generally not desirable in high-strength concrete applications because they negatively affect the overall performance of the concrete. Their irregular shapes lead to insufficient interlocking and lower density, which can ultimately reduce the strength and durability of the concrete when subjected to load and environmental conditions.

Examples & Analogies

Imagine trying to build a sturdy tower with different shaped blocks; if most of your blocks are flat and skinny (flaky and elongated), the structure will wobble and be weak. In contrast, using solid, block-shaped components is like using well-rounded aggregates, providing a strong and stable foundation.

Key Concepts

-

Aggregate Shape: Represents the geometry of the aggregates and significantly influences concrete properties such as workability and bond strength.

-

Rounded Aggregates: Smooth accumulations typically reducing bond strength but enhancing workability.

-

Angular Aggregates: Provides strength and interlock due to increased surface area, despite reducing workability.

-

Flaky and Elongated Aggregates: Both types reduce workability and strength, making them less desirable for high-strength concrete.

Examples & Applications

Using rounded aggregates for pedestrian walkways where high workability is required.

Choosing angular aggregates for structural components that require high load-bearing capacity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Rounded rocks roll with ease; angular ones give concrete strength, please!

Stories

Once upon a time, in a construction site, the rounded aggregates loved to party. They made everyone dance easily but couldn't hold up heavy roofs. The angular aggregates, however, while slow to unite, built mighty structures with their strength.

Memory Tools

Remember 'RAAF' - Rounded aggregates are for workability, Angular for strength, and avoid Flaky/Elongated.

Acronyms

FLE - Flaky and Elongated = Fewer Strength.

Flash Cards

Glossary

- Rounded Aggregates

Aggregates that are smooth and generally from natural river sources offering high workability but lower bond strength.

- Angular Aggregates

Crushed rock aggregates having high surface area and interlock, resulting in better strength but reduced workability.

- Flaky Aggregates

Aggregates whose thickness is less than 0.6 times their mean dimension, resulting in reduced workability and strength.

- Elongated Aggregates

Aggregates defined by having lengths more than 1.8 times their mean dimension, impairing both workability and strength.

Reference links

Supplementary resources to enhance your learning experience.