Applications of Fluid at Rest

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Manometers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we're going to learn about manometers, a vital tool in fluid mechanics for measuring pressure. Can anyone tell me what a manometer does?

Isn't it used to measure the pressure of fluids?

Absolutely! Manometers measure the pressure difference between two points using a liquid column. Remember, they come in different types, like U-tube manometers and inclined manometers. Does anyone remember what makes the inclined manometer special?

It helps measure low pressures more accurately, right?

Great! It's designed that way to amplify pressure readings compared to vertical manometers. Let's keep this in mind: 'Low pressure, inclined treasure' which serves as a memory aid.

What about the U-tube, how does it work?

Good question! A U-tube manometer uses a liquid to compare pressures at two different points. If the pressure at point A is greater, the liquid will move downward on the side connected to that point. What happens to the height difference in that case?

The height increases on the side of lower pressure?

Exactly! And this height difference is what we measure to find the pressure. Remember to equate the pressures at the same levels across the manometer. Now, let’s summarize the key points we learned today.

Manometers are devices used to measure fluid pressure, with inclined manometers amplifying low pressure readings. U-tube manometers help measure pressure differences. Always equate pressures at the same levels to determine height differences!

Applications of Hydrostatics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's move to how hydrostatics applies to real-world scenarios. Can anyone share why measuring pressure is important in fluids?

It helps in designing pipelines and tanks, right?

Absolutely! Measuring pressure impacts our designs. For instance, can you think of how ancient architects were influenced by hydrostatic pressure?

I remember hearing about stepped wells used for rainwater harvesting.

Exactly—stepped wells demonstrate the practical applications of pressure and fluid distribution systems! They were designed efficiently to provide water even in droughts. That’s a clever use of static fluids! Let's recap the key lessons.

Understanding hydrostatics helps us in practical applications like designing stepped wells and managing water resources effectively. Always remember to consider both pressure distributions and historical applications.

Differential Manometers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's delve into differential manometers. Does anyone know how they differ from standard manometers?

They measure the difference in pressure between two points instead of absolute pressure?

Correct! Differential manometers are specifically designed to detect pressure differences in flowing fluids. What applications can you think of for these devices?

They could help in measuring fluid flow rates in a pipeline.

Precisely! They are vital for monitoring flow rates and ensuring efficient system operation. A simple formula to remember is: pressure difference equals the difference in heights times densities. Let's recap this important point.

Differential manometers measure pressure differences between points and are essential for monitoring fluid systems. They help ensure overall efficiency and performance!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section discusses key applications of fluids at rest, particularly manometers used for measuring pressure in liquid systems, and describes various types of manometers, including U-tube and inclined manometers. It emphasizes the significance of pressure measurements across different surfaces and liquids in fluid mechanics.

Detailed

Applications of Fluid at Rest

This section addresses the applications of hydrostatic pressure in fluid mechanics, derived from the principles of fluid statics. The main focus is on manometers, devices used for measuring pressure in liquid systems, and the pressure distribution on inclined surfaces.

Key Applications

- Manometers: The concept of manometers is introduced, highlighting their simple construction which measures pressure through liquid height differences.

- Piezometer: A basic manometric device that reflects the pressure exerted by a fluid column.

- U-tube Manometer: A more advanced version that can use different liquids to measure the pressure difference between two points in a system.

- Inclined Manometer: Designed to enhance the sensitivity of pressure readings, especially for lower pressure ranges.

- Differential Manometers: Unlike standard manometers that measure absolute pressure at a single point, differential manometers measure pressure differences between two designated points in a piping system.

- Applications in Fluid Measurement: The section contains practical examples such as using these devices to measure fluid pressure in pipelines and to ascertain the forces acting on submerged surfaces. It also covers unique historical examples, such as stepped wells used for rainwater harvesting, demonstrating how ancient architects utilized hydrostatic principles effectively.

Through the discussion of these applications, the significance of understanding hydrostatic pressures in static fluids is made clear, which forms a foundational concept in fluid mechanics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Pressure Applications

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Welcome to this lecture on fluid mechanics. As we discussed in the last class fluid at rest and fluid statics we have derived basic equations of fluid statics. That is what the pressure equations with related to gravity field. So now, just we will have a two applications of the fluid at rest or hydrostatic pressure distributions that what I will address as a applications to two cases.

Detailed Explanation

In this chunk, the introduction to the lecture on fluid mechanics highlights the previous discussion about fluid at rest, also known as fluid statics, where fundamental equations relating to pressure due to gravity were derived. This sets the stage for discussing two significant applications: the manometer and pressure distribution on an inclined surface. The lecturer emphasizes the importance of hydrostatic pressure distributions in understanding the behavior of fluids that are not in motion.

Examples & Analogies

Consider how a still lake or a swimming pool demonstrates fluid at rest. The water at the bottom does not move but is still affected by the weight of the water above it. This pressure application is similar to how we will apply hydrostatic principles in practical scenarios like manometers and engineering structures.

Manometers Explained

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

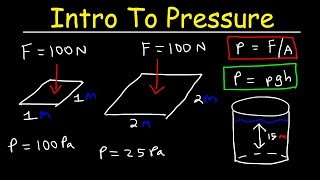

Now let us come to the manometer. Very simple devices are used to measure the pressure like you have a, let have these type of conduit, the pipes the carrying any liquids and you want to measure it what could be the pressure on that pipe. So we can just insert the tubes like you can see can have the tube like this or can have a tube like this with inclined and all or you can have a inclined like this.

Detailed Explanation

In this section, the lecturer introduces manometers, which are simple devices used for measuring the pressure of liquids in pipes. Manometers work by using a liquid column to measure pressure differences between two points. They can be designed in various shapes, such as vertical or inclined tubes. The flexibility in design allows for accurate pressure readings depending on the scenario, hence making them useful for various applications, including engineering and laboratory settings.

Examples & Analogies

Imagine a clear plastic straw immersed in a glass of water. When you cover the top of the straw and pull it out of the water, the water remains in the straw due to atmospheric pressure pushing up against it. This basic principle is akin to how a manometer measures the pressure in a pipe system.

Understanding Pressure Measurements through Piezometers

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The simplest form is a piezometer. What is showing here is a piezometer and to find out the pressure. If you know it pressure at this point is P . P = P . If I taking a point P here and this dimension is atm atm very small as compared to the length of height of this piezometer column.

Detailed Explanation

A piezometer is a specific type of manometer used for measuring static pressure in a fluid. It typically consists of a vertical tube connected to the liquid source. The height of the liquid column in the piezometer correlates with the pressure at that point in the system. If the pressure is atmospheric at the open end, the height of the liquid column measured gives the total pressure acting on the fluid in the pipe. This relationship allows for a straightforward calculation of pressure based on fluid height.

Examples & Analogies

Think of a water well where the water level shows how deep the water source is. The height of the water in the well responds to the surrounding atmospheric pressure in the same way the liquid column in a piezometer responds to pressure changes.

Inclined Manometers for Low Pressure Measurement

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Another case let we have an inclined manometer which is have a quite advantage in the sense that it amplifies the pressure reading as compared when you are talking about low pressure ranges. When you are measuring the low pressure ranges it being inclined so it is a give a easier for us to measure the low pressure as compared to the vertical one.

Detailed Explanation

Inclined manometers are designed to measure low-pressure differences with greater accuracy than vertical manometers. The inclination of the tube allows for a longer liquid column to be measured, which enhances sensitivity to small changes in pressure. This means that even minor variations in pressure can be detected and quantified more easily, making inclined manometers valuable in various laboratory and field applications.

Examples & Analogies

Consider trying to detect subtle changes in temperature with a thermometer. A thermometer with a long, thin tube will show changes more clearly compared to a stubby one. Similarly, an inclined manometer, with its longer measurement, can detect slight pressure changes efficiently.

Differential Manometers for Pressure Difference Measurement

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now there is another type of manometer which is called the differential manometers. As the name says that here, we do not measure a particular point pressure measurements where you consider two points. Because many of our applications, we are not worried about absolute pressure.

Detailed Explanation

Differential manometers are utilized to measure the pressure difference between two points in a fluid system. Unlike traditional manometers that measure absolute pressure, these instruments focus on the variance in pressure that drives fluid flow. This allows engineers and scientists to understand how systems perform under different pressures, which is crucial for designing and optimizing fluid systems.

Examples & Analogies

Think of differential manometers like a race between two runners. You care more about the difference in speed between them than their individual speeds. Similarly, in many fluid systems, understanding the pressure difference helps in evaluating performance more than knowing pressures at specific points.

Key Concepts

-

Manometers: Devices used for measuring fluid pressure.

-

Hydrostatic Pressure: The pressure exerted by a static fluid.

-

Pressure Distribution: Variation of fluid pressure across surfaces.

Examples & Applications

A U-tube manometer utilizing mercury to measure atmospheric pressure.

An inclined manometer used for low-pressure applications in HVAC systems.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When pressure is low, make the angle steep, with a manometer, your readings will reap.

Stories

Imagine an ancient well designer who uses his knowledge of water pressure to collect rain efficiently, conserving it for dry days ahead.

Memory Tools

P-MAD: P for Piezometer, M for Manometer, A for Applications, D for Differential manometer.

Acronyms

W-P-B

for Water

for Pressure

for Barometer.

Flash Cards

Glossary

- Manometer

A device used to measure fluid pressure by observing the height difference of a fluid column.

- Piezometer

The simplest form of a manometer used to measure pressure by the height of a fluid column.

- UTube Manometer

A manometer design where a U-shaped tube measures the pressure difference between two points.

- Inclined Manometer

A type of manometer that is inclined to improve measurement accuracy for low pressure ranges.

- Differential Manometer

A manometer that measures the pressure difference between two points within a fluid system.

- Hydrostatic Pressure

The pressure exerted by a fluid due to its weight at rest.

- Pressure Distribution

The variation of pressure across a surface or in a fluid column.

Reference links

Supplementary resources to enhance your learning experience.