Summary

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Manometers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to discuss manometers, which are essential tools in fluid mechanics for measuring pressure. Can anyone identify the simplest form of a manometer?

Is it a piezometer?

Exactly! A piezometer measures pressure by allowing the liquid to rise in a tube. Remember, it's based on the basic hydrostatic pressure equation. Can anyone recall what that is?

It's related to the height of the liquid column and its density, right?

Correct! The pressure at the base of the column is given by P = ρgh, where ρ is the density of the liquid, g is acceleration due to gravity, and h is the height of the liquid column.

What about inclined manometers? Why do we use them?

Great question! Inclined manometers help measure low pressures more accurately because the longer liquid column gives a more precise reading. This is crucial in applications like wind tunnels.

So, we can use them for measuring atmospheric pressure as well?

Yes! They amplify readings, making them more sensitive. Let's summarize: manometers, especially inclined ones, are vital tools for measuring pressure in various fluid systems.

Differential Manometers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on, let's talk about differential manometers. Who can tell me what makes them different from regular manometers?

They measure the difference in pressure between two points rather than absolute pressure, right?

Exactly! We're often concerned with differences in pressure in systems like pipelines. Can you think of a practical application for this?

Maybe in a pipe flow where we want to know how much pressure drop there is?

Excellent example! By placing a differential manometer between two points, we can monitor pressure losses, essential for calculating flow rates.

How do we determine the pressure difference using the manometer?

We equate the pressures at two points along a continuous fluid surface using fluid heights and densities, much like with regular manometers. Remember, accurately gauging these pressures helps optimize system designs.

Can we visualize these readings with an example?

Absolutely! Imagine two pipes carrying different viscous fluids. The difference in heights in the manometer indicates the pressure difference driving the flow, crucial for engineers.

Applications of Hydrostatics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Before we finish, let’s discuss real-world applications of these concepts. Has anyone heard of stepped wells?

I've heard they are used for water harvesting.

Correct! Stepped wells are designed to maximize water collection and are an ancient architectural marvel. They cleverly leverage hydrostatic principles to maintain water level even during droughts.

So, these principles of pressure and hydrostatic forces have been used for centuries?

Indeed! Understanding hydrostatics isn't just about theoretical pressure calculations; it directly impacts water resource management!

It sounds like there's much more to fluid mechanics than just equations!

Exactly! The principles we discussed today play crucial roles in engineering design and environmental sustainability. To summarize, manometers and differential manometers are essential tools for understanding fluid pressures, with applications that span from ancient architecture to modern engineering.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

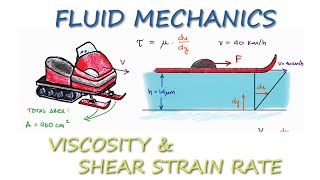

In this section, the lecture elaborates on manometers and differential manometers as practical devices to measure pressure differences in fluid systems, providing insights on their functioning, different types, and their significance. Key concepts such as hydrostatic pressure distributions, pressure equations, and practical examples related to stepped wells are also discussed.

Detailed

In this lecture on fluid mechanics, Prof. Subashisa Dutta explains the applications of hydrostatic pressure distributions, focusing on manometers and differential manometers. He begins by recapping fluid statics and the derived equations for pressure distributions, reinforcing the idea that pressure in a fluid at rest acts equally in all directions (Pascal’s Law). The section introduces manometers as simple devices that utilize fluid columns to measure pressure. Two types are explained: the vertical piezometer and the inclined manometer, the latter being more effective for low pressure readings due to its extended measurement length. The lecture illustrates how to compute pressure using these devices based on the principles of hydrostatics, density of the fluid, and the height of the liquid column. It also highlights differential manometers, stressing their utility in determining pressure differences rather than absolute pressures, which is essential in various applications like pipe flow systems. The significance of these concepts is further emphasized with historical examples of stepped wells used for water harvesting.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Recap of Fluid Statics

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In the last class as you know it, we discussed about fluid at rest. That is what I will have a recap. Then I will talk about the manometers. And then we will talk about differential manometer. And I will give you a very interesting examples of the stepped well, which was designed long back by ancient architecture and how they have designed the stepped well and that what we will discuss it. Then we will have the applications of hydrostatics that to find out the forces on the submerged surfaces and we will have the summary of this.

Detailed Explanation

In this chunk, we are reminded of the previous lesson focused on fluid statics, which is the study of fluids at rest. The speaker emphasizes that the discussion will evolve to practical applications, notably the use of manometers for measuring pressure. A historical example will also be provided involving stepped wells, illustrating how ancient civilizations ingeniously designed these structures for water storage. Finally, the chunk indicates that there will be a summary concerning the forces acting on submerged surfaces, tying together the application of hydrostatics.

Examples & Analogies

Think of fluid statics as understanding how water behaves in a calm pond. Just like when you drop a pebble and see the ripples, fluid statics explains the calm, still conditions before or after something disrupts the surface. The manometer analogy can be likened to using a straw to measure how deep a drink is in a glass—by observing the height of the liquid in the straw, you get a sense of the pressure pushing the liquid up against gravity.

Fundamentals of Manometers

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

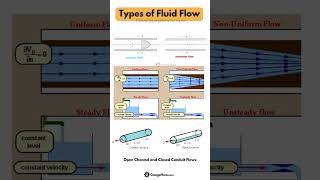

Now let us come to the manometer. Very simple devices are used to measure the pressure like you have a, let have these type of conduit, the pipes the carrying any liquids and you want to measure it what could be the pressure on that pipe. So we can just insert the tubes like you can see can have the tube like this or can have a tube like this with inclined and all or you can have a inclined like this. So each one having the merit and also disadvantages, like for examples, the manometer is simple device that is what use a liquid column to measure the pressure between two points.

Detailed Explanation

Manometers are essential instruments used for measuring the pressure in fluids, particularly in pipes that carry liquids. They consist of tubes that can be arranged vertically or inclined to capture the pressure readings. The simplicity of the manometer allows intuitive measurements via the height of a liquid column, indicating the difference between two pressure points in a confined space. Each type of arrangement (vertical, inclined) has unique benefits and limitations, affecting their accuracy and usability for different applications.

Examples & Analogies

Imagine your favorite sports drink bottle. When you squeeze the bottle, the liquid rises through the straw. A manometer works similarly; when you measure how high the liquid rises in the straw due to either the squeezing (pressure difference) or atmospheric conditions, you can tell how much pressure was applied. The inclined manometer might amplify the measurement like using a long straw, making it easier to drink from without much effort.

Use Cases for Differential Manometers

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now there is another type of manometer which is called the differential manometers. As the name says that here, we do not measure a particular point pressure measurements where you consider two points. Because many of our applications, we are not worried about absolute pressure. Mostly we are looking for the two points like I have the pipe and I have the point A and B. So this is a pipe flow, I have the point A and B. At this A and B locations, I want to know it what is the pressure difference between these two point of A and B in this pipe flow.

Detailed Explanation

Differential manometers are specialized devices for measuring the pressure difference between two points in a fluid system rather than measuring absolute pressure at any one location. This is particularly useful in scenarios where the difference in pressure drives the flow within a pipe system. By connecting the manometer to two different points (A and B) in a pipeline, operators can ascertain how much pressure is pushing the fluid from one point to another, allowing for effective monitoring and management of fluid systems.

Examples & Analogies

Think of driving a car. You don't just care about how much gas is in the tank (absolute pressure); you're more interested in how quickly the gas is used as you accelerate. Differential manometers help understand the 'acceleration' of fluid by showing the difference in 'fuel' pressure at two points, crucial for maintaining a smooth flow in piping systems.

Key Concepts

-

Manometer: A device to measure the pressure of fluids using liquid columns.

-

Differential Manometer: Measures pressure difference between two points.

-

Hydrostatics: Study of fluids at rest.

-

Pascal's Law: Indicates uniform pressure in all directions in a fluid at rest.

Examples & Applications

Using a piezometer to measure the water pressure in a vertical pipe.

Differential manometers are used in industrial applications to monitor fluid flow in pipes by measuring pressure differences.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Pressure's height, a liquid's plight, shows how strong it is at night.

Stories

Imagine a tall tower of water where the pressure increases at every level, showing us how deep the water truly impacts the base.

Memory Tools

P.M. - Pressure Measurement: Remember that for pressure, you often measure with a Manometer.

Acronyms

H.P. for Hydrostatics Pressure

Helps remember the fundamental connection of hydrostatics in pressure measurement.

Flash Cards

Glossary

- Pressure

The force exerted per unit area.

- Manometer

A device used to measure the pressure of a fluid.

- Differential Manometer

A device that measures the pressure difference between two points in a system.

- Hydrostatics

The study of fluids at rest and the forces and pressures associated with them.

- Piezometer

A type of manometer used to measure fluid pressure in a vertical column.

- Inclined Manometer

A manometer that is inclined to measure low pressure differences more accurately.

- Liquid Column

The height of a liquid in a tube that corresponds to the pressure in the system.

- Pascal's Law

States that pressure changes applied to an enclosed fluid are transmitted undiminished throughout the fluid.

Reference links

Supplementary resources to enhance your learning experience.