Micro Manometers

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Micro Manometers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore micro manometers, devices essential for measuring pressure differences between two points in a fluid system. Can anyone tell me what they understand about pressure measurement?

I think it’s about how we figure out the force applied by a fluid at certain points?

Exactly! Pressure is defined as force per unit area applied in all directions by a fluid. Micro manometers specifically use liquid columns to gauge these pressure differences. Let's remember it with the acronym 'PIME' - Pressure Indication by Manometer Effect.

What types of manometers are we discussing, specifically?

Types of Manometers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

There are various types of manometers. Can anyone name one?

What about the U-tube manometer?

Great! U-tube manometers show the difference in liquid height due to pressure differences. The inclined manometer is often used for lower pressure measurements. Remember the mnemonic 'RIDE' - Read Incline for Differential Errors, to help recall that.

What’s its benefit?

The inclined design extends the measurement length, allowing for more precise readings of low pressure differences.

How to Operate a Micro Manometer

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss how to operate these manometers effectively. Anyone wants to give it a try?

Do we measure height differences to find pressure?

Yes! The height difference in the liquid columns reflects the pressure difference using the equation P = ρgh, where ρ is the fluid density and g is acceleration due to gravity. A quick rhyme to remember that is 'Pressure climbs with height, in fluid's might.'

What if we have different fluids?

That's a great question! In cases of different fluids, we must consider their densities in our calculations. Use the correct density for accurate pressure difference measurement.

Applications of Micro Manometers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Micro manometers are essential in measuring pressures in industrial applications. Can anyone think of where we might use these?

In pipe systems, perhaps to monitor oil or water flows?

Correct! They help in understanding flow rates and detecting pressure loss. We'll use the mnemonic 'FLOWS' – Fluid Levels Observed with Sensors.

Are there specific industries that rely on them?

Yes, they are commonly used in chemical, petroleum, and water treatment industries!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section elaborates on micro manometers, detailing their functionality, types (including U-tube and inclined manometers), and applications in measuring pressure differences in various fluids. The significance of these devices in fluid mechanics and real-world applications is emphasized.

Detailed

Detailed Summary of Micro Manometers

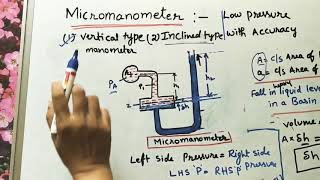

Micro manometers are simple yet effective devices used to measure pressure differences between two points in fluid systems. The primary focus of this section is on different types of manometers including U-tube manometers and inclined manometers, and their applications.

Key Points Covered:

- Definition and Functionality: Manometers utilize liquid columns to measure pressure differences. The basic principle relies on hydrostatic pressure which states that the pressure at any point in a fluid is the same at equal heights along a horizontal surface.

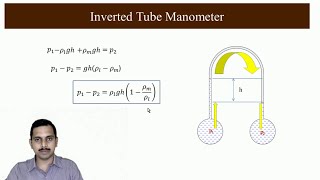

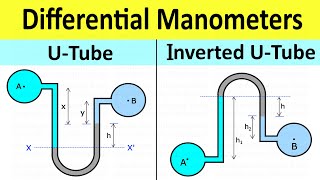

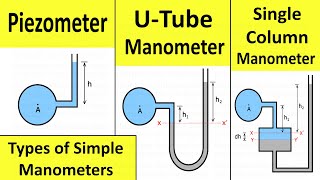

- Types of Manometers: The section outlines various types including:

- Piezometer: A basic form measuring pressure by the height of a liquid column.

- U-tube manometer: A more common design allowing for various fluids, providing advantages in distinguishing between heavier and lighter liquids.

- Inclined manometer: This type offers improved accuracy for low pressure measurements due to the amplification effect as the scale is inclined, resulting in longer measurement lengths.

- Differential Manometers: These measure the difference in pressure between two points in a fluid system instead of absolute pressures.

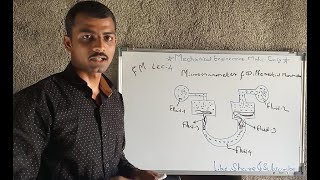

- Micro Manometers: A specialized application where a reservoir and flexible tubes are used to measure pressure differences in industrial applications. This design helps in measuring the pressure of flowing liquids and plays a critical role in monitoring flows in pipe networks.

Overall, understanding micro manometers is vital for applications in fluid mechanics, particularly in determining pressure changes and understanding fluid dynamics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Micro Manometers

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now there are a simplified micro manometers are there which is a measure the pressure difference between A and B and you have the flow. This flow may be carrying oil or maybe carrying slurry. It maybe carrying any industrial if you look it the any industry is a lot of pipe networks and we have to measure the pressure difference between two points, which is required to measure the discharge, to measure the frictional losses and all.

Detailed Explanation

In industrial settings, measuring the pressure difference between two points in a pipeline is crucial. This measurement allows engineers and operators to understand how much fluid is flowing through the system and to identify any potential losses, such as those due to friction. Micro manometers simplify this process by using devices that can accurately measure these small differences in pressure, especially where precise adjustments are needed, such as in oil or slurry transport.

Examples & Analogies

Imagine you are trying to fill a balloon with air using a pump. If the balloon has a small hole, you'll notice that the balloon will not inflate as expected despite the air being pumped in. A micro manometer in this scenario can help identify the pressure difference between the pump and the balloon's interior, helping you understand the effect of the leak.

Components of a Micro Manometer

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Here what we do it, we use a reservoir here okay. It is bigger, then a inclined pipe. Then we have a flexible tube which connected to between point A and the reservoir. Another flexible tube is connecting the point B other end of the reservoir.

Detailed Explanation

A micro manometer typically consists of a main reservoir that helps to stabilize the reading. This reservoir is larger than the inclined pipe sections, which helps to measure smaller pressure changes accurately. Flexible tubes connect the pressure points (A and B) to the reservoir, allowing for fluid transfer and adjustment based on pressure differences. The design ensures that as pressure changes occur, the height of the liquid in the reservoir can adjust, providing a readable measurement.

Examples & Analogies

Think of a water level indicator in a home. When one tap is turned on, the water flows through different pipes, and the indicator shows the change in pressure or flow level. Similarly, the micro manometer gives readings based on the pressure differences between the points, helping manage the fluid system effectively.

How it Works: Measuring Pressure Difference

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When the flow will be there, there will be a pressure difference. That pressure difference will cause the difference in the height of this case. And these mechanical screw arrangements with a pressure reading as equivalent as the screw goes up and down the what could be the as equivalent to pressure that what is written on this graduated scale on the stand.

Detailed Explanation

Micro manometers work by detecting changes in fluid height that correspond to pressure changes. As the flow moves through the pipes, it creates variations in pressure that can elevate or lower the liquid level in the reservoir. The height difference translates directly to pressure differences, which are read off on a calibrated scale. Mechanical screws fine-tune the level to ensure it reads accurately, turning the height measurement into a quantifiable pressure reading.

Examples & Analogies

Imagine using a weighing scale where instead of measuring weight, you are measuring pressure through the height of water. Just as you would turn a dial to adjust the scale for precise measurement, the micro manometer uses a screw to calibrate readings based on fluid height to accurately indicate pressure changes in the system.

Adjusting the Reference Level

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Here just to we rotate the screw till make it the reference level and that lifting up this reservoir and the screw arrangement will give us a reading at this point which is the pressure difference between these two points.

Detailed Explanation

To ensure accurate readings, the micro manometer allows for adjustments to the reference level. By rotating the screw, the operator can raise or lower the liquid reservoir until it indicates zero pressure difference. This ensures that subsequent measurements taken are relative to a known baseline, improving precision in determining the pressure differences as the system operates.

Examples & Analogies

Think of leveling a spirit level used in construction. You adjust the bubble in the glass to ensure your measurements are accurate. Similarly, by adjusting the screw on the micro manometer, you are 'leveling' the system for precise pressure readings, ensuring that every change is measured correctly.

Key Concepts

-

Types of Manometers: Including U-tube, inclined, and differential manometers, each serving distinct functions in measuring pressure.

-

Micro Manometer Purpose: Specialized for measuring pressure differences effectively in industrial scenarios.

-

Equilibrium of Pressure: The relationship of pressure within fluids at equilibrium and the significance of height differences.

Examples & Applications

Example of a U-tube manometer measuring the pressure difference in a water pipe.

Example of an inclined manometer used to monitor low pressure in air conditioning systems.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To measure pressure small or great, a manometer's your best mate.

Stories

Imagine a tiny man with different liquids—they measure pressures in the finest details, revealing secrets of flows.

Memory Tools

Use 'PASTE' to remember: Pressure Adjustment with Specific Tubes' Embodied.

Acronyms

Remember the acronym 'PIME' - Pressure Indication by Manometer Effect.

Flash Cards

Glossary

- Micro Manometer

A device used for measuring small pressure differences in fluid systems.

- Piezometer

A simple type of manometer that measures the pressure of liquid by the height of a liquid column.

- Utube Manometer

Manometer comprising a U-shaped tube used to measure the pressure difference between two points.

- Inclined Manometer

A more accurate manometer that is tilted to amplify small pressure readings.

- Differential Manometer

A type of manometer used to measure the difference in pressure between two points.

Reference links

Supplementary resources to enhance your learning experience.