Applying Linear Momentum Equations

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Stress Tensors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll start by understanding the concept of stress tensors. In fluid mechanics, a stress tensor helps define the forces acting on a unit area. Can anyone tell me how many components a stress tensor has?

Isn't it nine components, including both normal and shear stresses?

Exactly, Student_1! The nine components include three normal stress components and six shear stress components. Remember this with the mnemonic 'Shear Stresses Double!' Can someone explain why these components are important?

They help us understand the behavior of fluids under different forces!

Great, Student_2! Stress tensors give us a comprehensive view of how fluids react to forces, which is critical in engineering applications.

Control Volumes and Surface Forces

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about control volumes. When we apply linear momentum equations, why do we prefer using control volumes?

I think it's because it simplifies the calculation of forces acting on a system!

Correct, Student_3! Control volumes allow us to isolate a fluid portion to examine the forces more effectively. What do we typically consider when calculating the total force on a control volume?

The body forces and surface forces?

Exactly! We denote the total force acting on the control volume as the sum of body forces and surface forces. Remember this with the acronym 'BAS' - Body And Surface forces.

Nullifying Atmospheric Pressure

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's explore atmospheric pressure's role in fluid dynamics. Why do we generally nullify atmospheric pressure in our calculations?

Because it acts uniformly across the control surface and cancels out!

That's right! Since it cancels out, we prefer using gauge pressure. What effect does this have on our calculations?

It simplifies the pressure distribution we need to account for!

Exactly! By focusing on gauge pressure, we streamline our equations and focus on the net forces that truly matter for the fluid’s behavior.

Reynolds Transport Theorem

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

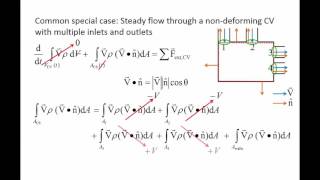

Next, let's discuss the Reynolds transport theorem. Can anyone explain how we relate momentum and net forces within control volumes?

Isn't it that we relate the mass and acceleration through total forces acting on the volume?

Spot on, Student_3! Force can be expressed as mass times acceleration, which is crucial when analyzing net momentum flows. What happens to momentum flux if we have multiple inlets and outlets?

We need to compute the net momentum flux coming in and going out!

Correct! By evaluating these fluxes, we can derive the net forces acting on our control volume, providing deeper insight into the fluid dynamics.

Momentum Flux Correction Factors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s cover momentum flux correction factors. Why are these correction factors essential when using average velocities in real fluid flow?

Because the velocity distribution can vary, right?

Exactly, Student_1! When we have non-uniform velocity distributions, we use correction factors to ensure our calculations of momentum flux are accurate. What’s the takeaway when we compute using average velocity?

We should always account for the correction factors to get the right results!

Right again! Remember the phrase 'Average = Adjust!' to keep in mind the importance of correction factors in fluid dynamics.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

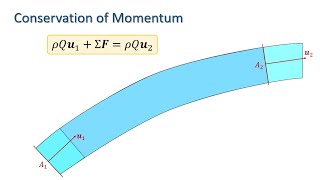

The application of linear momentum equations involves understanding stress tensors, surface forces, body forces, and how these forces interact within control volumes. It also emphasizes the significance of gauge pressure and how atmospheric pressure can be nullified during calculations to simplify fluid dynamics problems.

Detailed

Detailed Summary

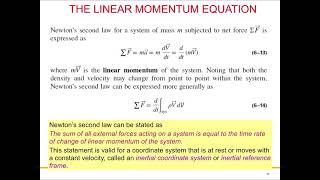

In this section, the foundational concepts of applying linear momentum equations in fluid mechanics are elaborated. The stress tensor is introduced as a tool for defining surface forces, consisting of nine components that include normal and shear stresses. Normal stresses arise from pressure forces and viscous forces, while shear stresses arise solely from viscous forces.

To solve fluid dynamics problems, the section discusses how control volumes can be strategically selected to simplify the evaluation of forces acting within fluid flows. The atmospheric pressure's contribution to total force can effectively be nullified by integrating over a control surface, leading to the use of gauge pressure in calculations.

The section further explains the Reynolds transport theorem, linking system-level forces to mass and acceleration at a control volume level. Various scenarios such as fixed control volumes and the impact of momentum flux across inflows and outflows are covered, establishing the relationship between mass flow rates and net momentum flux. The significance of momentum flux correction factors for averaging velocity distributions in real fluid flow conditions is also highlighted.

Through this in-depth analysis, the transition from theoretical concepts to practical applications is emphasized, equipping students with the ability to apply linear momentum equations in various fluid mechanics problems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Stress Tensors

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, if you come back to the surface forces, like for example, for tetrahedral structures like this where you have dx, dy, and dz components are there, and your axis is like this, x direction, y direction, and z direction. So, you can define the surface forces as a stress tensor. Stress means what, force per unit area. So, you can define as a stress tensor. So, this stress will have nine components. You could have this knowledge in solid mechanics. I am just repeating it. There is not much difference between solid mechanics and fluid mechanics when you consider at stress level.

Detailed Explanation

Stress tensors are mathematical objects that help us describe how forces are distributed over a surface area. In three-dimensional space, we have three axes: x, y, and z. Each axis can have components acting on it, leading to a total of nine components of stress in the tensor. The diagonal components of the tensor represent normal stresses (forces acting perpendicular to the surface), while the off-diagonal components represent shear stresses (forces acting parallel to the surface). Understanding this concept is essential because it provides a foundation for analyzing surface forces on objects in both solid and fluid mechanics.

Examples & Analogies

Think of pushing down on a soft sponge that has been cut into a cube. The pressure from your hand exerts a stress on the sponge's surface. If you apply a force on one face, the sponge compresses and the stress can be described with a tensor, showing how the force is distributed. If the same sponge was in water, similar principles apply, but now we consider fluid pressures acting on all faces of the sponge. This understanding helps engineers design structures that can withstand different types of forces.

Surface Forces and Integrals

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, we have stress tensors in order to describe all surface force components. That is what will have nine components which will have, as you know the subscript describes that. The stress in the z direction acting on the face whose normal is eight directions. This is similar notation to what we use in solid mechanics. So, you have the stress tensor coordinate systems defining nine stress components...

Detailed Explanation

The nine components of the stress tensor are crucial for understanding how different forces act on a given surface. By recognizing which forces are normal or shear, engineers can calculate the resultant forces using integrals over the surface. This involves resolving these stress components depending on their direction and magnitude, which is necessary for analyzing forces on structures or fluid interfaces.

Examples & Analogies

Imagine a tomato sitting on a cutting board. The pressure you apply from above creates normal stress directed downward through the tomato, and if you were to slice it, the knife would create shear stresses as the blade moves through the flesh. By understanding how these stresses work on a surface, chefs and engineers can better design cutting tools or food processing equipment.

Body Forces and Surface Forces

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Total surface force acting on a control surface. The body force component will have volume integrals of rho g dV, g is the vector quantity as we consider the g, acceleration due to gravity can have a vector commodity with three scalar components of g, g, g...

Detailed Explanation

In fluid mechanics, forces acting on a control volume are categorized into body forces (forces that act throughout the volume, like gravity) and surface forces (forces that act on the boundaries of the volume, like pressure or viscous forces). The body force due to gravity is represented by the integral of the weight across the control volume, while the surface forces can often be quantified using stress tensors. Understanding these forces allows for better predictions of how fluids will behave under different conditions.

Examples & Analogies

Consider a swimming pool filled with water. The weight of the water provides a body force acting downwards due to gravity. Each side of the pool also bears pressure forces acting due to the water pressing against the walls. Engineers consider both these types of forces when designing structures to ensure they can withstand the weight of the water and the forces exerted by it.

Neglecting Atmospheric Pressure

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, if I take a control volume, everywhere I will have atmospheric pressure, then the absolute pressure from some locations. So, if I consider the atmospheric pressure is acting throughout this control surface and do surface integral, if the pressure is having the direction, and if I do a surface integrals over this, it will be cancelled out and becomes 0...

Detailed Explanation

Atmospheric pressure acts uniformly in all directions over a control volume. When performing calculations for fluid dynamics, it is common to neglect this pressure during surface integrals because its effects effectively cancel out when integrated over a closed surface. Instead, engineers focus on gauge pressure, which is the pressure relative to atmospheric pressure. This simplification allows for more manageable calculations without losing accuracy in the results.

Examples & Analogies

When you're inflating a balloon, the air pressure inside is higher than the atmospheric pressure outside. However, if you're measuring the change in pressure while inflating, all you care about is how much pressure is over and above the atmospheric level (gauge pressure). Just like that, we often ignore the atmospheric pressure when calculating forces in fluids since it exerts the same force in all directions.

Control Volume Selection

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, another point is how to choose control volume, because that is what the art is, like you do free body diagrams in solving solid mechanics problems. Similar way, drawing the appropriate control volume is an art...

Detailed Explanation

Choosing an appropriate control volume is key to simplifying fluid dynamics problems. A well-defined control volume will allow you to clearly identify inflow and outflow conditions, making it easier to apply conservation laws. The location and shape of the control volume selected will significantly determine how straightforward the problem is to solve. Engineers often practice this skill to become proficient in applying fluid dynamics principles effectively.

Examples & Analogies

Imagine trying to find out how much water is flowing out of a garden hose. If you select a control volume that only includes the end of the hose, it's easy to measure and understand the flow rate. However, if your control volume extends back into the tap, the water pressure and movement changes complicate your readings and calculations. Selecting a proper control volume simplifies such problems.

Reynolds Transport Theorem

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, coming back to applying the Reynolds transport theorem we have to write the linear momentum equations. At this systems level force is equal to mass into acceleration...

Detailed Explanation

The Reynolds transport theorem relates the change in momentum of a system to the flow of mass and momentum through its boundaries. It forms the basis for deriving momentum equations used in fluid dynamics, allowing us to analyze complex systems. By incorporating both body and surface forces into a mathematical framework, engineers can model and predict fluid behavior under various conditions accurately.

Examples & Analogies

Think of a moving car that changes speed or direction. The forces acting on it, like engine power and wind resistance, can be analyzed using similar principles as Reynolds transport theorem in fluid mechanics. This analogy helps illustrate how changes in flowing fluids relate to forces acting on objects. Just as we can derive equations of motion for cars, we can derive equations for fluids using this theorem.

Key Concepts

-

Stress Tensor: A mathematical representation of stress in fluids, containing normal and shear stress components.

-

Control Volume: An essential tool in fluid mechanics for analyzing the forces and momentum changes.

-

Gauge Pressure: The pressure measurement that reflects only the pressure exerted by the fluid, excluding atmospheric influence.

-

Body Force: Forces acting throughout the fluid volume, typically gravitational.

Examples & Applications

When water flows through a pipe, the stresses on the pipe walls can be analyzed using stress tensors to determine effects from pressure and viscous forces.

In a dam structure, one can calculate the forces acting on different sections using control volume methods, nullifying atmospheric pressure to focus on gauge pressure.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In fluid forces we play, gauge pressure leads the way!

Stories

Imagine a water reservoir, where every drop pushes down while balancing against the air above, and the gauge pressure tells us the true story without atmospheric noise.

Memory Tools

Remember 'BAS' for Body and Surface forces in control volumes!

Acronyms

Use 'SHeS' for remembering Shear and Hess for stress components.

Flash Cards

Glossary

- Stress Tensor

A mathematical construct that describes the state of stress at a point in a material, encompassing both normal and shear stresses.

- Normal Stress

Stress that acts perpendicular to the surface, arising from pressure forces and viscous forces.

- Shear Stress

Stress that acts parallel to the surface, resulting from viscosity in a fluid.

- Control Volume

A defined region in space used to analyze the fluid flow and forces acting upon it.

- Gauge Pressure

The pressure measurement that excludes atmospheric pressure.

- Body Force

A force that acts throughout the volume of a fluid, such as gravitational forces.

Reference links

Supplementary resources to enhance your learning experience.