Surface Force Acting on a Differential Surface Element

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Stress Tensors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore stress tensors and how they represent surface forces. Can anyone tell me what stress means in a mechanical context?

Isn't stress just force per unit area?

Exactly, great job! Stress is defined as force per unit area, and in fluid mechanics, we often express this as a tensor. Does anyone know how many components are in a stress tensor?

Nine components, right?

Correct! Each component corresponds to different stress conditions. Remember the acronym 'NSSS' for Normal and Shear Stress Components. Let’s move on to discuss what these components represent.

Normal vs Shear Stresses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we know about the stress tensor, can someone explain the difference between normal stresses and shear stresses?

Normal stresses act perpendicular to a surface, while shear stresses are parallel to it.

Exactly! Normal stresses are associated with pressure and can be influenced by viscous forces, while shear stresses arise from viscosity itself. Let's visualize this by imagining how fluids behave at rest versus moving.

So, when fluid is in motion, we’re more concerned about shear stresses?

Precisely! Thus, understanding this distinction is vital when analyzing flow dynamics.

Applying Control Volume Concepts

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

We’re now going to explore how these stress components act within a control volume. Can anyone explain what a control volume is?

It’s a defined volume in which we analyze the balance of forces and mass.

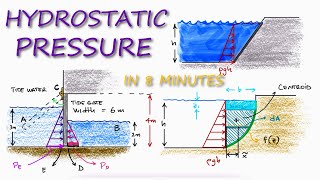

Great! When we apply this to stress tensors, we need to perform surface integrals. Can anyone remind us why atmospheric pressure is often ignored in these calculations?

Because it cancels out when we do the integration!

Exactly! This simplifies our calculations significantly when assessing systems like tanks or pipes. Remember to always look for those cancellations!

Total Force and Application in Engineering Problems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s connect this back to real-world applications. How do we separate forces acting due to pressure from those due to viscosity?

We can look at them individually when they don’t influence each other much.

Correct! For many engineering applications, if viscous effects are negligible, we can simplify our equations significantly. Can anyone think of a case where this could be applied?

In plumbing systems, often pressure is the primary factor above viscosity.

Correct again! Utilizing these concepts effectively allows us to analyze systems efficiently.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section explains the definition of surface forces in fluid mechanics using stress tensors. It explores the nine components of stress in Cartesian coordinates, differentiating between normal and shear stresses, and discusses the significance of these components in determining the total force acting on a control volume.

Detailed

Surface Force Acting on a Differential Surface Element

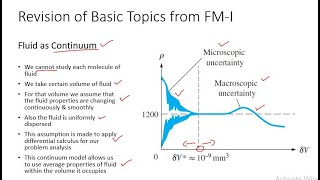

This section focuses on the concept of surface forces acting on a differential surface element, emphasizing the use of a stress tensor to describe these forces. In both fluid and solid mechanics, surface forces are characterized by stress, which is defined as force per unit area. The stress tensor has nine components, defined in a Cartesian coordinate system that includes normal and shear stresses.

- Stress Tensor: Comprises nine components that include both normal and shear stresses acting on different surfaces, classified as:

- Normal Stresses: Forces acting perpendicular to the surface, significant in understanding pressure and viscosity interactions.

- Shear Stresses: Forces acting tangentially to the surface, critical for evaluating viscous forces.

- Total Force Components: The total force acting on a control volume includes body forces (like gravitational forces) and surface forces, which require surface integrals for calculations. The equations derived from these integrals help analyze fluid flow dynamics.

- Control Volume Analysis: Understanding how to select control volumes wisely is essential for simplifying complex fluid mechanics problems. The concept of ignoring atmospheric pressure when calculating net forces further clarifies the necessary analytical steps when analyzing systems such as pipes and tanks.

This section serves as a fundamental framework in fluid mechanics, allowing us to analyze how forces interact and affect the behavior of fluids in various engineering contexts.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Stress Tensor Definition

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

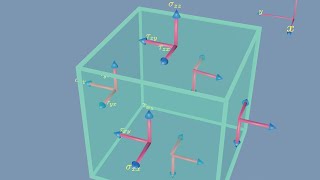

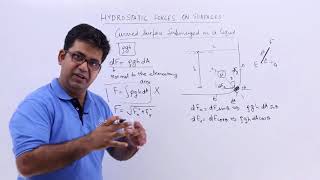

Now, if you come back to the surface forces, like for example, for tetrahedral structures like this where you have dx, dy, and dz components are there, and your axis is like this, x direction, y direction, and z direction. So, you can define the surface forces as a stress tensor. Stress means what, force per unit area. So, you can define as a stress tensor. So, this stress will have nine components. You could have this knowledge in solid mechanics. I am just repeating it. There is not much difference between solid mechanics and fluid mechanics when you consider at stress level. So, we have stress tensors in order to describe all surface force components.

Detailed Explanation

The stress tensor is an important concept in understanding how surfaces interact with forces in fluid and solid mechanics. When we refer to surface forces, we must think about how these forces are distributed across a small area, or 'differential surface element'. In engineering terms, stress is defined as force applied over a unit area. The stress tensor incorporates both normal stresses (perpendicular to the surface) and shear stresses (parallel to the surface). In three-dimensional space, particularly in tetrahedral structures, there are three axes (x, y, z), leading to a total of nine components in the stress tensor, representing interactions in all directions. This foundational knowledge is essential in both fluid and solid mechanics.

Examples & Analogies

Think of a stress tensor like a set of hands pushing against a flexible surface. Each 'hand' represents a different direction of force (the three axes: x, y, and z). When multiple hands push at once, you can imagine how they create different effects on the surface. Some hands might press directly down (normal stress), while others might slide along the surface (shear stress). Understanding how these various forces combine helps engineers design stable structures.

Components of the Stress Tensor

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, this stress will have nine components. You could have this knowledge in solid mechanics. That is what will have nine components which will have, as you know the subscript describes that. The stress in the z direction acting on the face whose normal is eight directions. This is similar notation to what we use in solid mechanics.

Detailed Explanation

The nine components of the stress tensor are organized into a matrix format, which is key for engineers when analyzing forces acting on materials. Each entry in this matrix corresponds to a different direction and type of stress acting on a differential surface element. For example, the normal stress is associated with forces acting perpendicular to the surface, while shear stresses are related to forces acting along the surface. This systematic approach allows engineers to analyze complex loading conditions effectively.

Examples & Analogies

Imagine a soccer ball being kicked in various directions. Each kick represents a different stress component. The kicks that strike the ball face-on cause a direct impact (normal stress), while kicks that graze its side create a slide (shear stress). Analyzing how the ball reacts to these different stress components gives a clear idea of how it will behave under various scenarios.

Normal and Shear Stresses

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, basically these are the viscous terms. So, over the surface we can define it, which is the shear stress components or the viscous stress component. So, these nine components of stress in Cartesian coordinate is defined in this surface.

Detailed Explanation

Within the context of fluid mechanics, distinguishing between normal and shear stresses is crucial. Normal stresses can be a mix of both pressure from the fluid and any viscous effects, while shear stresses are specifically related to the fluid's viscosity. This separation allows engineers to identify how a material or fluid will behave under different loading conditions and informs design decisions to ensure structural integrity.

Examples & Analogies

Consider a tablecloth being pulled at one end. The forces acting perpendicular to the table (normal stress) keep the tablecloth close to the surface, but the forces along the table’s surface as it gets pulled (shear stress) determine how easily the cloth moves. Understanding how these forces interact helps in designing better household items like non-slip tablecloths.

Integrating Stress Components

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, if I have the stress component there and I have the normal vectors, if I resolve the force components, I will have the scalar product between the stress tensor and the n vectors, that is how we do it. And for the total surface area we do surface integrals to compute it.

Detailed Explanation

To compute the total force acting on a surface due to the stress tensor, engineers use mathematical operations called surface integrals. The basic idea is to take the stress at each point on the surface (represented by the stress tensor) and multiply it by the corresponding normal vector, which gives the direction of the surface. By integrating these products over the total surface area, we acquire a comprehensive understanding of the total force acting on that surface from all the different stress components.

Examples & Analogies

Imagine you have a large cake that you want to cut into pieces. Each slice has different weights depending on the frosting, filling, and fruit on top. To know the total weight of the whole cake, you'd weigh each slice and add them together. Similarly, engineers measure the stress at various points on a surface and 'add them up' using integration to find the total force acting on that surface.

Body Forces and Surface Forces

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Total force acting on control volume will have the body force component and surface force component.

Detailed Explanation

In fluid mechanics, the total force acting on a control volume involves two main components: body forces and surface forces. Body forces are those that act throughout the volume of the fluid, such as gravity (the weight of the fluid), while surface forces are the result of stresses acting at the boundaries of that volume. Understanding both types of forces is vital for analyzing system stability and behavior under various conditions.

Examples & Analogies

Think of a hot air balloon. The buoyant force (body force) lifts the balloon up through the air, while the friction between the surface of the balloon and the air (surface forces) plays a crucial role in determining how quickly it can ascend or maneuver. Together, these forces dictate the balloon's flight behavior.

Key Concepts

-

Stress Tensor: A nine-component mathematical representation of stress encompassing both normal and shear stresses.

-

Control Volume: A defined volume where we analyze forces and mass balances during fluid flow.

-

Normal and Shear Stress: Normal stress acts perpendicular to a surface, while shear stress acts parallel.

Examples & Applications

Calculating the total force acted upon a submerged surface using surface integrals that involve the stress tensor.

Evaluating a control volume for fluid flowing through a pipe where the atmospheric pressure effects cancel out.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Stress tensor, stress tensor, nine components to see, normal and shear, helping set the free.

Stories

Imagine a partitioned room where each wall feels different forces – some push straight (normal), others slide along (shear). The gray area in between? That’s where stress lives!

Memory Tools

NSSS: 'Normal Stresses for Shear Support' to remember the types of stress in fluid mechanics.

Acronyms

Control Volume Analysis

C.V.A. Remember

Simplifications

Integrations

Evaluations!

Flash Cards

Glossary

- Stress Tensor

A mathematical representation of stress at a point in a material, encompassing normal and shear stress components.

- Normal Stress

Stress component acting perpendicular to a surface.

- Shear Stress

Stress component acting parallel to a surface.

- Control Volume

A specified volume in space through which mass and momentum can flow for analysis.

- Surface Integrals

Mathematical integration performed over a surface to compute forces or fluxes.

Reference links

Supplementary resources to enhance your learning experience.