Total Surface Force Acting on Control Surface

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Stress Tensors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore how surface forces in fluid mechanics are represented using stress tensors. Does anyone know how many components are in a stress tensor?

I think it has six components?

Close! In three dimensions, a stress tensor actually has nine components. They represent stresses in different directions, like shearing and normal stresses. Let’s remember this with the acronym 'SNEE' — Stress Nine Every Element. Can you all say that?

SNEE!

Great! Now, to clarify, what distinguishes normal stress from shear stress?

Normal stress is caused by pressure or force perpendicular to the surface, whereas shear stress is parallel!

Exactly! Normal stresses arise due to pressure or viscosity, while shear stresses only relate to viscosity. Let's summarize these distinctions.

Integrating Surface Forces

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've established what stress tensors are, let's talk about how we use integrals to find total surface forces. What do we consider when resolving these forces?

We need to account for both surface forces and body forces.

Correct! We use surface integrals to compute the force acting on our control surface. Why is it important to also consider body forces?

Because they affect the overall force balance in the fluid!

Absolutely! And by integrating over the entire control volume, we include every influence on our force calculation. Can anyone think of a practical example where surface forces dominate?

In a pipe flow scenario, where viscosity affects the flow strongly?

Exactly right! Let’s remember — ‘Flow at Pipe Dictates Pressure’ to recall this relationship.

Simplifying Assumptions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

When simplifying our calculations, what kinds of assumptions might we make about surface forces?

If certain forces, like viscous forces, are negligible?

Exactly! In many engineering problems, particularly at lower velocities, we may ignore some forces. Remember our phrase: 'Neglect Non-dominant.' How does that impact our calculations?

It makes our equations simpler to use!

Right! This simplicity is crucial for solving practical problems efficiently. If you find it useful, try to implement 'Neglect Non-dominant' in your future studies!

Importance of Gauge Pressure

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

For calculating forces, why do we focus on gauge pressure instead of absolute pressure?

Because gauge pressure accounts for the pressure difference from atmospheric pressure?

Correct! Since atmospheric pressure is uniform and acts equally in all directions, it cancels out in our surface integrals. Just remember — 'Gauge Over Absolute, for Simplicity.' Let's keep honing our understanding of how pressure impacts our calculations.

Visualizing Control Volumes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s take a moment to visualize control volumes. Why is choosing the right control volume crucial in fluid problems?

It helps us maximize our relevant data while minimizing complexity!

Absolutely! Every time you work through a fluid problem, remember our phrase — 'Control Clearly, Solve Simply.' How will you apply this in your next task?

I’ll ensure I define my control volumes based on clear parameters!

Fantastic! Let’s wrap up discussing that fluid mechanics is all about clarity and simplification when modeling real-world scenarios.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section explains how surface forces in fluid mechanics can be described through a stress tensor, which has nine components representing normal stress and shear stress. It emphasizes the importance of integrating these forces across the control volume to understand how they interact with body forces, particularly under varying conditions of pressure and viscosity.

Detailed

In this section, we delve into the interaction of surface forces acting on a control surface within fluid mechanics, drawing parallels with solid mechanics. A stress tensor is employed to articulate these forces, encompassing nine distinct components that reflect stress in multiple directions (x, y, and z). Normal stresses, resultant from pressure and viscous forces, and shear stresses, arising exclusively from viscous influences, are also defined in this context. The integration of these forces over differential surface elements, combined with volume integrals to account for body forces, leads us to calculate the total surface force on control volumes. The discussion also notes the simplifications possible in engineering scenarios, particularly under conditions where the influence of certain forces can be neglected. Establishing these foundational equations allows for clearer applications of linear momentum equations related to fluid flow.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Surface Forces and Stress Tensor

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

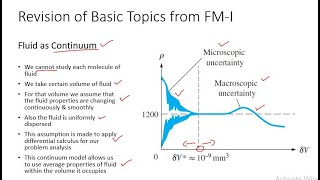

Now, if you come back to the surface forces, like for example, for tetrahedral structures like this where you have dx, dy, and dz components are there, and your axis is like this, x direction, y direction, and z direction. So, you can define the surface forces as a stress tensor. Stress means what, force per unit area. So, you can define as a stress tensor. So, this stress will have nine components. You could have this knowledge in solid mechanics. I am just repeating it. There is not much difference between solid mechanics and fluid mechanics when you consider at stress level.

Detailed Explanation

In this chunk, we begin with the concept of surface forces in fluid mechanics. The text emphasizes that surface forces can be represented through a mathematical concept known as a 'stress tensor.' A stress tensor helps us capture all the forces acting on a surface in three-dimensional space. Specifically, it breaks down the forces into components that are aligned with the axes: x, y, and z. In total, there are nine components of this tensor. This parallel between solid mechanics and fluid mechanics highlights that both fields handle forces in similar ways, despite their different contexts.

Examples & Analogies

Think of the stress tensor like a family tree where each member represents a different force acting on a structure (like a building). The three axes correspond to different branches of the tree, showcasing how each member (force) interacts with others. Just like each family member impacts the family's health, each force affects the structure's stability.

Components of the Stress Tensor

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, you have the stress tensor coordinate systems defining nine stress components. If you look at that, if you take this diagonal component which is the normal component to this surface like these are all normal components. That means these are compositions of the pressure force and the viscous force component. But the diagonal component what we have is acting tangentially. So, basically these are the viscous terms.

Detailed Explanation

This chunk discusses the specific components of the stress tensor. The nine components include diagonal and off-diagonal elements. The diagonal elements represent normal stresses acting perpendicular to surfaces, while the off-diagonal elements represent shear stresses acting tangentially. Normal stresses arise from both pressure forces and viscous forces; this differentiation is significant in fluid dynamics, helping us understand how fluids exert forces on surfaces.

Examples & Analogies

Imagine a sponge in water. The pressure from the water pushes perpendicularly (normal stress) into the sponge, while the water trying to squeeze past the sponge's fibers generates a tangential force (viscous stress). Understanding these stresses helps engineers assess how structures interact with fluids.

Calculating Total Surface Force

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Total force acting on the control volume will have the body force component and surface force component. The body force component will have volume integrals of rho g dV, g is the vector quantity as we consider the g, acceleration due to gravity can have a vector commodity with three scalar components of g , g , g . That means what I am defining is g = g I + g j + g k.

Detailed Explanation

This segment introduces the concept of calculating the total surface force acting on a control volume. It states that the total force can be broken down into two main components: body forces, which are due to gravity and can be calculated using volume integrals, and surface forces, which come from pressures and viscous stresses acting on the surfaces. The gravitational force is expressed with the density (rho) of the fluid and the acceleration due to gravity (g), which has three components corresponding to the three spatial dimensions.

Examples & Analogies

Think of a swimming pool. The water in the pool exerts a force downward due to its weight (body force) and also pushes against the sides and bottom through pressure (surface forces). Calculating the total force involves adding these two aspects together to ensure the pool can handle the pressure without breaking.

Simplifying Force Calculations

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If you look at these things, it looks very complicated. We cannot apply simple example problems that we encounter as a civil engineer or mechanical engineer. What is the total force acting on the surface will be the body force and the surface force and this two integrals will tell me, one is volume integrals and other is surface integrals.

Detailed Explanation

Here, the text highlights the complexity of calculating forces acting on surfaces and control volumes in engineering problems. It stresses that the total force comprises contributions from both body forces and surface forces, which are represented by volume and surface integrals, respectively. The author indicates that, although challenging, understanding these integrals is crucial for solving engineering problems.

Examples & Analogies

Consider designing a bridge. Engineers need to calculate the forces on the bridge's surface (from wind and vehicles) and the weight of the materials (body forces). By practicing how to set up these calculations correctly, engineers can ensure a robust and safe design.

Effect of Atmospheric Pressure

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If I consider the atmospheric pressure is acting throughout this control surface and do surface integral, if the pressure is having the direction, and if I do a surface integrals over this, it will be cancelled out and becomes 0.

Detailed Explanation

This chunk focuses on how atmospheric pressure impacts calculations. When dealing with control volumes, atmospheric pressure acts uniformly in all directions. If engineers conduct a surface integral of the atmospheric pressure across a control volume, the net effect cancels out to zero due to symmetry. This leads to the simplification of considering only gauge pressure for practical problems.

Examples & Analogies

Think of an open balloon. The pressure on the inside and outside is balanced, resulting in no net force pushing the balloon in any direction. This balance is essential in engineering as it allows for clean calculations by ignoring the atmospheric pressure in controlled environments.

Choosing the Control Volume

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, another point is how to choose control volume, because that is what the art is. Like you do free body diagrams in solving solid mechanics problems. Similar way, drawing the appropriate control volume is an art.

Detailed Explanation

In this part, the importance of choosing the correct control volume is discussed. Just as using free body diagrams in solid mechanics is critical, selecting the right control volume is equally vital in fluid mechanics. A well-defined control volume can simplify the analysis of complex problems, leading to more accurate results. It requires practice and good judgment to decide on an effective boundary to examine the forces and flow behaviors accurately.

Examples & Analogies

Consider a chef making soup. The chef must choose the right pot (control volume) to cook the ingredients. A small pot might overflow (poor choice), while a pot that's too big could waste energy. Just as the chef's choice affects the cooking process, engineers must make wise choices about control volumes to achieve optimal solutions.

Key Concepts

-

Surface Forces: Forces acting on the boundary of a fluid control volume.

-

Stress Tensor: A mathematical tool for analyzing stress within fluids, with nine distinct components.

-

Normal Stress vs. Shear Stress: Normal stress acts perpendicular to surfaces, while shear stress acts parallel.

-

Control Volume Analysis: A technique for simplifying fluid mechanics problems by defining a volume of interest.

-

Gauge Pressure Significance: In fluid calculations, gauge pressure is used as it accounts for atmospheric pressure differences.

Examples & Applications

Example of a control volume over a fluid flowing through a pipe to illustrate how surface forces and body forces are integrated.

An application of normal versus shear stress in a flowing fluid around an object, such as a ball, demonstrating the significance of both types of stress.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Forces that are all around, stress tensors can be found. With nine in view, normal follows true.

Stories

Imagine a river with varying currents acting on a bridge; the forces through stress tensors describe the strains and balances that help engineers design strong supports.

Memory Tools

SNEE - Stress Nine Every Element: Remembering the nine components of stress tensors.

Acronyms

NSEC - Normal stress, Shear stress, Equivalent force, Control volume

The essentials of fluid in mechanics.

Flash Cards

Glossary

- Stress Tensor

A mathematical representation used to depict stress in a material, having components that denote normal and shear stresses.

- Normal Stress

The component of stress perpendicular to a surface, typically caused by pressure or axial forces.

- Shear Stress

The component of stress parallel to a surface, primarily arising from forces that cause layers of material to slide past one another.

- Control Volume

An imaginary or real boundary defined for analyzing fluid flow and forces acting on the system.

- Gauge Pressure

The pressure relative to atmospheric pressure, commonly used in fluid dynamics equations.

Reference links

Supplementary resources to enhance your learning experience.