Momentum Equations and Control Volumes

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Stress Tensors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into stress tensors. Remember, stress is defined as force per unit area. What does this mean in fluid dynamics?

It means we are looking at how forces act on fluid surfaces.

Exactly! A stress tensor captures the pressure and viscous forces experienced by a fluid. It's a matrix describing stress in three dimensions.

So, what are the components of this stress tensor?

Good question! There are nine components in the tensor: the diagonal elements represent normal stresses, while the off-diagonal ones correspond to shear stresses. Remember this: Normal stresses are related to pressure and viscous effects, while shear stresses mainly derive from viscosity.

How do we use these in practice?

We calculate integrations of these tensors over control volumes to analyze forces acting on fluids. The integration process helps us understand overall effects.

Can you summarize today's main takeaways?

Certainly! Key points: stress is a force per area, stress tensors capture fluid stress states, and they consist of nine components. These are used in calculations of forces in control volumes.

Control Volumes and Body Forces

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss control volumes. A control volume is an arbitrary volume in space where we analyze fluid behavior. Why is this important?

It helps focus on fluid interactions without worrying about flow outside this volume.

Exactly! Control volumes simplify our calculations. So, we separate forces acting on a fluid: body forces, like gravity, and surface forces, like pressure and viscous forces acting on the surfaces.

How do we calculate these forces?

For body forces, we integrate the density multiplied by the gravitational acceleration over the volume. For surface forces, we need to integrate pressure over the surfaces of the control volume.

What happens when we ignore atmospheric pressure?

Excellent! Often, we assume atmospheric pressure cancels out in a closed system—thus we work with gauge pressures to simplify our equations.

Can we sum this up?

Sure! Control volumes focus our analysis, separating body and surface forces, with an emphasis on volume and surface integrals for calculations.

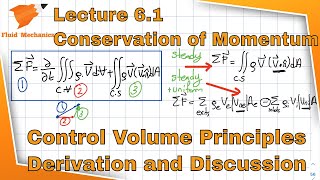

Applying the Reynolds Transport Theorem

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s delve into the Reynolds Transport Theorem (RTT). Why is it crucial for momentum equations?

Is it because it connects fluid properties and forces with the control volume concept?

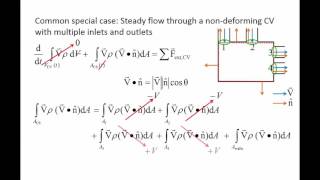

Spot on! RTT allows us to convert a system description into a control volume description effectively. We can represent momentum flux using RTT.

And what’s the key equation here?

The key relationship is force equals mass times acceleration. In control volumes, we express this as integrals of velocity for momentum flux. Remember, we need to consider the velocity vector correctly!

Can you clarify those integrals again?

Yes! The left-hand side is the net momentum flux through the control volume, and the right-hand side corresponds to the forces acting on it, including body forces and pressures.

And can we wrap this session up?

Absolutely! Reynolds Transport Theorem connects forces and momentum for control volumes, using integrals for calculations.

Momentum Flux and Correction Factors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To finish our unit, let’s address momentum flux and why we need correction factors.

Is it because the velocity may not be uniform at the inflow?

Absolutely! Momentum flux can vary due to velocity profiles, especially in real fluid systems. So, we introduce correction factors to account for these variations accurately.

How do we calculate these correction factors?

These factors involve integrals over the velocity distribution and relate average velocity to the actual flux experienced within a flow system.

And could we summarize what we learned today?

Sure! We learned that momentum flux varies due to velocity distributions, requiring correction factors for accurate calculations. This ensures our fluid dynamic analyses are precise for different scenarios.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, the relationship between surface forces, stress tensors, and control volumes is explored. It explains how these concepts tie into the equations of motion for fluids and the significance of separating body force and surface force in practical applications.

Detailed

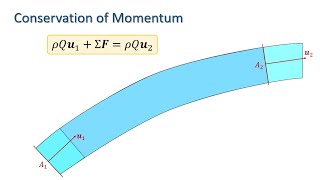

Momentum Equations and Control Volumes

This section introduces the concepts of momentum in fluid mechanics, specifically focusing on surface forces and control volumes. It begins by defining stress tensors, which encapsulate both normal and shear stress components experienced by fluids in motion. The discussion emphasizes that fluid mechanics shares foundational principles with solid mechanics, particularly regarding stress analysis.

Stress tensors are defined in a Cartesian coordinate system, typically expressed as a 3x3 matrix comprising components that describe stress in different directions. The diagonal elements relate to normal stress (comprising pressure and viscous forces), while the off-diagonal elements signify shear stresses. A fundamental aspect of analyzing these stresses involves integrating these components over specified control volumes.

The text further explores how to evaluate the total force acting on a control volume by distinguishing between body forces (e.g., gravitational forces) and surface forces deriving from the fluid's pressure and viscosity. The significance of simplified control volumes, particularly where atmospheric pressure influences are mitigated, is also mentioned, as it simplifies calculations related to gauge pressure.

Moreover, the section outlines the importance of selecting appropriate control volumes and geometries when applying the Reynolds Transport Theorem (RTT) to momentum equations. It discusses how to analyze flow systems with inflow and outflow using momentum flux and highlights methods for correcting momentum calculations using average velocity concepts and correction factors. By articulating these principles, this section lays the groundwork for further applications and problem-solving in the realm of fluid mechanics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Surface Forces and Stress Tensors

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, if you come back to the surface forces, like for example, for tetrahedral structures where you have dx, dy, and dz components, and your axis is like this, x direction, y direction, and z direction. You can define the surface forces as a stress tensor. Stress means what, force per unit area. So, you can define as a stress tensor. This stress will have nine components. You could have this knowledge in solid mechanics. There is not much difference between solid mechanics and fluid mechanics when you consider stress levels. We have stress tensors in order to describe all surface force components. That is what will have nine components.

Detailed Explanation

This chunk discusses surface forces in three-dimensional (3D) contexts, particularly in tetrahedral structures. It introduces the concept of a stress tensor, which mathematically describes how forces are distributed over a given surface area. A stress tensor has nine components, reflecting forces acting in different directions—including normal (perpendicular to a surface) and shear (parallel to a surface) forces. Stress is essentially the relationship between force and area, critical in both solid and fluid mechanics.

Examples & Analogies

Imagine pressing your hand on a table. The force from your hand (the stress) is spread over the part of your hand that contacts the table (the area). If you press harder (more force), the stress increases. Now, consider a 3D object like a tetrahedron, which has multiple surfaces and directions for these forces to act. The stress tensor represents this distribution of force across all those surfaces and directions.

Normal and Shear Stresses

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The diagonal component of the stress tensor includes normal stresses, which are compositions of the pressure force and the viscous force component. The non-diagonal components represent shear stresses, which are solely due to viscous forces. Thus, we can define normal stress as the sum of pressure and viscous stresses, while shear stresses are defined by the viscous stress alone.

Detailed Explanation

In fluid mechanics, stress can be divided into two categories: normal stress and shear stress. Normal stresses are the forces acting perpendicular to surface areas, including those arising from fluid pressure and viscosity. Shear stresses are due to the fluid's viscosity, acting parallel to surfaces. It's important to clearly differentiate these types of stress since they have different effects on fluid motion and behavior.

Examples & Analogies

Think of a water balloon. When you squeeze it, the pressure inside increases (normal stress), which pushes outward on all sides. However, if you try to twist the balloon, you're applying shear stress, causing the layers of water to slide over each other. Understanding these stresses helps explain how fluids behave in various situations, such as in pipes or during flow over surfaces.

Total Forces on Control Volumes

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The total force acting on the control volume will have the body force component and surface force component. The body force component will have volume integrals of \(\rho g dV\), with \(g\) defining the gravitational acceleration vector with three components (\(g_x, g_y, g_z\)). Thus, integration over the control volume provides the total forces acting on the control volume.

Detailed Explanation

In fluid dynamics, when analyzing a control volume, we consider all forces acting on it. This includes body forces (like gravity, expressed mathematically as volume integrals of the product of fluid density \(\rho\) and gravitational acceleration \(g\)) and surface forces (arising from pressure and shear stresses on the control surface). By integrating these forces, we can find the net force acting on the volume, which is crucial for applying momentum equations.

Examples & Analogies

Consider a swimming pool. The weight of the water (the body force) pushes down on the floor (gravity acting throughout the volume of water), while the water pressing against the sides and bottom (surface forces) also contributes to the overall forces in the pool. By analyzing both the body forces and surface forces, we can understand how the pool walls withstand the water pressure.

Simplification in Control Volume Analysis

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When applying linear momentum equations to a control volume, it's often valid to neglect atmospheric pressure forces because they cancel out. We focus on gauge pressure instead while accounting only for the forces that contribute meaningfully to the fluid dynamics involved.

Detailed Explanation

In fluid dynamics, when we analyze control volumes, atmospheric pressure is generally uniform and acts in all directions. Because of this symmetry, when we perform integrals across the control surface, the effects of atmospheric pressure effectively cancel out. Thus, we can simplify our calculations by considering only the gauge pressure within the fluid, allowing for easier problem-solving.

Examples & Analogies

Imagine cooking pasta. When you pour water into a pot, the atmospheric pressure (like a blanket over the pot) is pushing down on the surface of the water. However, inside the pot, the pressure from the weight of the water and any added salt (gauge pressure) is what's really affecting the boiling point. We often overlook the atmospheric pressure to simplify our calculations, focusing instead on what changes inside the pot.

Choosing Control Volumes

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The selection of control volume is crucial in fluid mechanics. Appropriately defined control volumes ensure that we can easily analyze the forces, velocities, and other parameters. Depending on the problem, control volume areas can be selected strategically to simplify calculations and understand fluid dynamics better.

Detailed Explanation

Choosing an appropriate control volume involves identifying the region of fluid flow you want to analyze and ensuring that it's well-defined in terms of boundaries (surfaces) and applicable forces. The selection impacts how easily you can apply equations of motion, conservation laws, and other mathematical tools to gain insight into the fluid behavior.

Examples & Analogies

Think about adding a spice mixture to a sieve while cooking. If you choose to observe just the area around the sieve, it’s easier to see how the spices flow through compared to analyzing the entire kitchen. Similarly, when fluid engineers define control volumes, they are like chefs picking their mise en place – focusing on specific, relevant areas to simplify their calculations.

Reynolds Transport Theorem and Momentum Equations

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Applying the Reynolds transport theorem, the linear momentum equations relate the forces acting on the control volume to the rate of momentum flow across the control surfaces. This equation accounts for the dynamics of both fluid flow and forces acting in the system.

Detailed Explanation

The Reynolds transport theorem provides a framework for relating changes in momentum within a control volume to the momentum flux across its boundaries. This approach allows engineers to systematically analyze how forces influence fluid motion, making it easier to design systems that manage fluids effectively.

Examples & Analogies

Consider a car driving through a tunnel. The air (fluids) enters and leaves the tunnel, and as it does, there’s a relationship between how fast it flows in and the forces (like push from the car) that affect that motion. Similarly, the Reynolds transport theorem gives a mathematical approach to understanding those dynamics, accounting for both the incoming and outgoing fluid flow.

Key Concepts

-

Stress Tensor: A matrix representing stress in fluids, comprising nine components.

-

Control Volume: An arbitrary volume for analyzing fluid behavior and forces.

-

Body Force: Force like gravity acting throughout the volume of a fluid.

-

Surface Force: External force acting on a surface of a control volume, includes pressure and viscous forces.

-

Reynolds Transport Theorem: Connects system and control volume analysis in fluid dynamics.

-

Momentum Flux: Motion transfer per unit area, based on mass and velocity.

-

Correction Factors: Adjustments made to account for non-uniform velocity profiles in fluid dynamics.

Examples & Applications

A practical scenario involves water flowing through a pipe where surface and body forces are analyzed using control volumes. The atmospheric pressures cancel out, simplifying calculations.

When computing momentum flux for a fluid jet impacting a surface, correction factors are used to account for velocity gradients.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Stress tensors show, normal and shear; in fluid mechanics, they’re quite clear!

Stories

Imagine a water balloon, pressure is felt everywhere. The stress tensor captures that, from every single layer!

Memory Tools

B.S. Control: Body Surface Control volumes help find the total forces at play.

Acronyms

S-C-R

Stress Tensor

Control Volume

Reynolds Theorem—they're the core of fluid mechanics.

Flash Cards

Glossary

- Stress Tensor

A mathematical representation of stress, capturing normal and shear stresses in a fluid.

- Control Volume

An arbitrary volume in space used for analyzing fluid behaviors and calculations.

- Body Force

Forces acting throughout the volume of a fluid, such as gravity.

- Surface Force

Forces acting at the surface of a fluid, primarily due to pressure and viscous effects.

- Reynolds Transport Theorem (RTT)

A theorem that relates the change in a quantity in a system to the flow across a control volume.

- Momentum Flux

The quantity of motion transferred through a unit area, related to mass flow and velocity.

- Correction Factor

A factor introduced to account for non-uniform velocity distributions in fluid dynamics.

Reference links

Supplementary resources to enhance your learning experience.