Special Cases in Momentum Flux

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Stress Tensors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll start by discussing **stress tensors**. Can anyone tell me what a stress tensor represents?

Isn't it related to forces acting on areas, like 'force per unit area'?

Exactly right! Stress tensors quantify surface forces in fluids by detailing how they are distributed across different axes. Each tensor has nine components representing normal and shear stresses.

What can you tell me about normal versus shear stress?

The diagonal components of the tensor are normal stresses, which relate to pressure and viscous forces. Those off-diagonal components represent shear stresses. Remember: 'Normal stresses are diagonal; shear stresses are off-diagonal'.

So, what's the practical use of these in real calculations?

Great question! We use stress tensors to calculate forces on control volumes, integrating these stresses to find total forces acting.

In summary, stress tensors help us quantify fluid forces, essential for understanding momentum flux in various flows.

Applying Control Volumes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's delve into **control volumes**. What do you think is the importance of choosing a good control volume in fluid mechanics?

I think it helps in simplifying the analysis of fluid systems?

That's correct! By choosing appropriate control volumes, we can isolate specific sections of flow to focus our analysis and calculations.

How do we define the control volumes effectively?

A key factor is aligning the velocity vector with the normal vector of the control surface. If they align at 0° or 180°, our calculations simplify significantly.

Can you give an example of when this alignment matters?

Of course! Consider a pipe with fluid flowing through it. If we align the control volume such that the inflow normal aligns with the velocity, we can easily compute the momentum flux without complex integrals.

In closing, effective control volume selection is critical for simplifying momentum calculations. Always look to align your vectors!

Momentum Flux and Correction Factors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on, let’s discuss **momentum flux**. Who can explain how we calculate momentum flux across a control volume?

Isn't it just mass flow rate multiplied by velocity?

Spot on! We calculate momentum flux as mass flow rate times velocity. However, for non-uniform flows, we need to introduce a correction factor to consider variations in velocity distribution.

What exactly is a correction factor?

Great question! The correction factor accounts for how the average velocity may differ from the actual velocity profile of the fluid. For example, in laminar flow in a pipe, the velocity isn’t uniform, hence the factor adjusts our calculations.

So, does this mean we can get more accurate results in our momentum calculations?

Absolutely! By incorporating correction factors, we enhance the precision of our momentum flux calculations, which is vital in practical engineering applications.

To sum up, momentum flux is central to fluid mechanics, and using correction factors ensures our calculations reflect real flow conditions accurately.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section delves into the relations between momentum flux, surface forces, and the role of stress tensors in fluid mechanics. It discusses the importance of distinguishing between normal and shear stress components, and the application of control volumes to analyze systems under different flow conditions, including the assumptions made for simplifying calculations in engineering applications.

Detailed

Detailed Summary

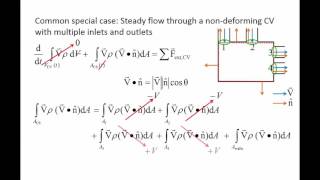

In this section, we investigate the momentum flux and its special cases in fluid mechanics. The discussion begins with the concept of surface forces represented through stress tensors, which comprise nine distinct components that reflect both normal and shear stresses.

The text explains how the diagonal components relate to pressure and viscous forces, thus underpinning the significance of stress tensors in both fluid and solid mechanics.

Further, the discussion extends to how forces act on a differential surface element and introduces the integration methods for computing total force acting on a control volume, emphasizing the contributions from body forces and surface forces. A critical element is the simplification of these forces, particularly when atmospheric pressure effects are nullified within calculations, allowing engineers to focus solely on gauge pressures.

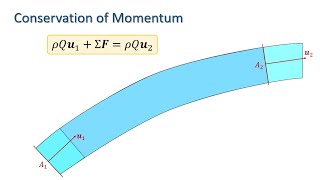

The text also emphasizes the art of choosing control volumes effectively in engineering scenarios, illustrating this with examples of inflows and outflows in pipelines. Key mathematical relationships are presented, revealing how momentum flux contributes to net force evaluations in fluid systems. Special emphasis is placed on using average velocities and introducing correction factors for momentum flux.

Overall, the section emphasizes the synergy between theoretical concepts and practical applications, providing insights essential for understanding fluid behavior in engineering design.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Momentum Flux

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, if I consider a fixed control volume, you have a series of inflows like 1 and 2 are the inflows, and 3, 4, and 5 are the outflows. So, through this control surface if you look, we are talking about not only the mass flux coming into this control volume but we are talking about momentum flux.

Detailed Explanation

In this section, we explore the concept of momentum flux in fluid dynamics. Momentum flux is essentially the rate at which momentum passes through a certain area. Accordingly, in this fixed control volume setup, we have multiple entrances and exits (inflows and outflows). The inflows contribute to the momentum entering the control volume, while the outflows account for the momentum leaving. Therefore, we calculate the net momentum flux by taking into consideration all these flow rates entering and leaving the control volume.

Examples & Analogies

Imagine a busy water park where water flows into various pools (inflows) and out through drains (outflows). The combined amount of water flowing in versus flowing out determines how much water is actually accumulating in the pools. Similarly, in our control volume, we assess how much momentum enters versus exits to understand the overall momentum change.

Calculating Momentum Flux

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The momentum flux will be the mass flux, mass per unit time into the velocity, that is what will be the momentum flux. Through this control volume, what is the momentum flux coming into? Through this control volume what is the momentum flux going out?

Detailed Explanation

To compute the momentum flux, we multiply the mass flow rate by the velocity of the fluid. By applying this principle, we can calculate the momentum flux both entering and exiting from our control volume. This is crucial in identifying how much momentum is retained or lost during the flow process. When we analyze inflow and outflow, we can perform surface integrals to quantify these values, leading us to determine the net momentum change in the control volume.

Examples & Analogies

Think of it as measuring the flow of cars entering and exiting a parking lot. The cars entering (mass flux) multiplied by their speed (velocity) gives you the 'momentum' of cars entering the lot. If you calculate the momentum of cars exiting in the same way, you can see if more cars are accumulating in the lot or if it's emptying out.

Momentum Equation Derivation

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Here, we are talking about net momentum flux passing through this control volume which will be equal to the net force acting on this control volume.

Detailed Explanation

The net momentum flux through the control volume is critical in defining how forces act on that volume. According to Newton's second law, the force is related to the rate of change of momentum in a moving system. Hence, if we know the momentum coming in and going out, we can equate this to the net force acting on the control volume, allowing us to analyze fluid behavior effectively.

Examples & Analogies

Consider a large ship moving through water. As it sails (an inflow of momentum), it pushes water away (exits). If we analyze the momentum of the water it pushes and the momentum of the ship itself, we can understand the forces that keep the ship navigating smoothly.

Applying Momentum Correction Factors

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If you look that way, now we can write the momentum equations in different forms considering the velocity distribution.

Detailed Explanation

In real-world applications, fluid flow is rarely uniform. When calculating momentum flux, it is essential to take into account velocity distributions across different sections. This is where momentum correction factors come into play. By applying correction factors, we can adjust our calculations to reflect the variation in velocity, ensuring our results more accurately represent the behavior of the fluid.

Examples & Analogies

Think about how people move in a crowded room. In some areas, people might be walking slowly while in others they may be moving quickly. If you're trying to measure 'movement contribution' in such a room, you wouldn't use a single average speed! You'd want to adjust your calculations to consider those areas of fast and slow moving groups, which is exactly what applying momentum correction factors helps us do.

Key Concepts

-

Surface Forces: Forces acting on a surface within a fluid, represented by stress tensors.

-

Stress Tensor Components: Nine components that indicate normal and shear stresses within fluids.

-

Control Volume Analysis: Method of isolating a section of flow to apply conservation laws for momentum and mass.

-

Momentum Flux: The product of mass flow rate and velocity, representing momentum transfer.

-

Correction Factors: Adjustments made in calculations to account for non-uniform velocity distributions.

Examples & Applications

Example 1: In a pipeline system with varying diameter, the momentum flux can be calculated using the average flow velocity and adjustment for the velocity profile.

Example 2: When analyzing a tank discharging fluid, the control volume can simplify the analysis of inflow and outflow by focusing on the momentum changes.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Stress tensors show, forces flow, normal and shear both do glow.

Stories

Imagine a fluid moving through a pipe; as it flows, it pushes against walls differently—some parts push harder, just like friends pushing on a swing set, needing to balance pressure!

Memory Tools

To remember normal and shear stress: 'Normal = N, Shear = S' - just think of N as Neat, and S as Slide!

Acronyms

For Control Volume

for Clear

for Values—Collect and Validate!

Flash Cards

Glossary

- Stress Tensor

A mathematical construct that represents the internal forces acting on a material, defined by its nine components corresponding to normal and shear stresses.

- Normal Stress

The component of stress acting perpendicular to a given surface, resulting from pressure and viscous forces.

- Shear Stress

The component of stress acting parallel to a given surface, arising from viscous effects in fluids.

- Control Volume

A defined region in space used for analyzing fluid flow, where mass, momentum, and energy balances can be applied.

- Momentum Flux

The rate of momentum transfer through a unit area, calculated as the product of mass flow rate and velocity.

- Correction Factor

A multiplier applied to account for variations in velocity distribution when calculating momentum flux in non-uniform flow scenarios.

Reference links

Supplementary resources to enhance your learning experience.