Choosing Control Volume

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Stress Tensors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing stress tensors and their role in fluid mechanics. Can anyone tell me how many components stress tensors have?

Nine components, right?

Exactly! We describe these with subscripts indicating the normal and shear stresses. Think of it like this—stress is force per unit area, a fundamental concept in solid mechanics too. So why do you think we need to understand this in fluid mechanics?

It helps us analyze how fluids exert force on surfaces?

Perfect! Remember that the diagonal components of the stress tensor represent normal stresses, while the off-diagonal components represent shear or viscous stresses.

So they can help us distinguish between different types of forces at play?

Exactly! By understanding how these forces act on a control volume, we can predict fluid behavior accurately. Let's move to calculating total forces next.

Body Forces and Surface Forces

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, who can define what we mean by body forces?

Body forces are forces that act throughout the volume of the fluid, such as gravity.

Right! And we can calculate body forces using volume integrals of density times gravitational acceleration. Does anyone remember how we represent gravitational force?

It's represented as a vector with components in the x, y, and z directions?

Exactly! Now, surface forces are a bit different. These include pressure forces and viscous forces, which we analyze through surface integrals. Can you think of a scenario where we would primarily deal with surface forces?

In a pipe flow, where fluid is exerting pressure against the walls?

Spot on! Understanding both of these forces is key to solving fluid dynamics problems. Now let's talk about integrating these forces.

Integrating Forces on Control Volumes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

When we integrate forces over a control volume, what kinds of integrals do we often use?

Surface integrals for surface forces and volume integrals for body forces?

Correct! Now these integrations allow us to compute the total force acting on the control volume. But why must we take special care when using gauge versus absolute pressure?

Because the effects of atmospheric pressure can cancel out in a closed control volume?

Exactly! When performing calculations, it's essential to focus solely on gauge pressures because atmospheric effects are uniform across the control surfaces.

So we simplify our calculations by ignoring the atmospheric pressure?

That's exactly the strategy! It streamlines our calculations while maintaining accuracy. Let's summarize.

Choosing the Control Volume

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, moving to an essential engineering skill—how do we choose an appropriate control volume?

By understanding the geometry of the fluid flow and the forces acting on it?

Exactly! The shape and placement of the control volume can really influence our analysis results. Can anyone share an example of this in a practical scenario?

Maybe in a water jet scenario, where we need to analyze the forces on a nozzle?

Spot on! Making those layout choices is crucial, particularly for achieving accurate results. We will practice this further with examples in our next session.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, the author elaborates on choosing control volumes in the field of fluid mechanics, explaining the significance of stress tensors, surface forces, body forces, and how these factors influence engineering problems. It emphasizes the necessity of selecting the correct control volume shape and alignment to accurately solve fluid dynamics problems.

Detailed

Choosing Control Volume

This section thoroughly discusses the concept of control volumes in fluid mechanics, particularly focusing on the dynamics of surface forces acting on these volumes.

Key Points Covered:

- Stress Tensor and Surface Forces: In fluid mechanics, similar to solid mechanics, the surface forces acting within a control volume can be characterized using stress tensors, which contain nine components—reflecting variations in normal and shear stresses. This allows engineers to analyze both pressure and viscous forces acting on fluid.

- Body Forces: Introduced alongside surface forces, body forces include gravitational forces acting on the volume. The segment elaborately discusses calculating these forces through volume integrals that account for distributed mass across the control volume.

- Integrating Forces: The section explains the method of integrating surface and body forces to arrive at total resultant forces, a crucial step when setting up equations for system dynamics in fluid mechanics.

- Gauge vs. Absolute Pressure: Emphasis is placed on the distinction between gauge and absolute pressure, with the former being critical during calculations, especially in cases where atmospheric pressure components average out to zero through integration in closed control volumes.

- Choosing the Control Volume: The text elaborates on the importance of strategically defining the control volume to facilitate simplifications without sacrificing accuracy. The discussion includes illustrative examples highlighting how pressure distributions may simplify when developing control volume diagrams for fluid flow problems.

Conclusion:

The section underscores the intricate balance between theoretical understanding and practical application when engineers choose control volumes, aligning fluid dynamics concepts with real-world problem solving.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

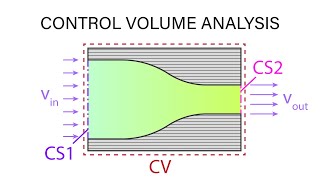

Introduction to Control Volume Concept

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

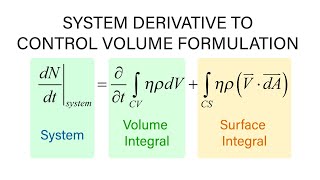

Now, if I have the stress component there and I have the normal vectors, if I resolve the force components, I will have the scalar product between the stress tensor and the n vectors, that is how we do it. And for the total surface area we do surface integrals to compute it.

Detailed Explanation

In this chunk, we introduce the concept of a control volume, which is used to analyze physical problems, particularly in fluid mechanics. A control volume is a defined region in space through which fluid can flow. To analyze forces acting on this volume, we start by identifying stress components and their directions using normal vectors. The scalar product of the stress tensor (which represents stress distribution across the surface of the volume) and the normal vectors is calculated as it helps in determining the forces acting on the control surface. By using surface integrals, we can compute total surface forces acting on the control volume, which is crucial for understanding fluid behavior within that volume.

Examples & Analogies

Imagine a water tank. The tank can be thought of as a control volume. If we want to analyze how forces from the water (like pressure) act on the tank's walls, we can use normal vectors to represent the directions in which these forces act. Just like measuring how much weight is pressing on the sides of the tank, we can calculate the total force using surface integrals over the tank's surface.

Components of Stress in Control Volume

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Total force acting on the control volume will have the body force component and surface force component. The body force component will have volume integrals of rho g dV.

Detailed Explanation

This chunk explains that when analyzing forces acting on a control volume, we identify two main components: body forces and surface forces. Body forces include effects like gravity, which are distributed throughout the volume of the fluid. The body force is calculated using a volume integral of the fluid density (rho) and gravitational acceleration (g). Surface forces, on the other hand, are those acting at the boundaries of the control volume, influenced by pressures or shear stresses. Both types of forces need to be considered to understand the overall behavior of fluids within the control volume.

Examples & Analogies

Consider a swimming pool filled with water. The gravity acting on the water creates body forces pulling the water downwards. If you were to analyze the pool as a control volume, you would calculate the body force due to gravity throughout the volume of water. At the same time, you would also look at how the pressure from the water's surface pushes against the walls of the pool—a surface force acting on the pool's structure.

Choosing the Right Control Volume

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

it is engineering skill or art to be developed by the students how to use the control volume concept.

Detailed Explanation

In this chunk, we emphasize the importance of selecting an appropriate control volume for problem-solving in fluid mechanics. Similar to drawing a free body diagram in solid mechanics, engineers must learn to define the control volume effectively to simplify and solve flow problems. The right control volume can make the problem more manageable by clearly identifying inflow, outflow, and forces acting on the system. The choice can drastically change the complexity of the calculations involved.

Examples & Analogies

Think of it like taking a photograph. You can choose what to include in your frame (the control volume) to highlight the main subject. If you zoom in on a subject (the control volume), you can detail how light and shadows play on that object. However, if you zoom out (consider a larger control volume), you might miss important details but capture the broader context. In engineering, the way you define your control volume can greatly affect your analysis and solutions.

Factors Affecting Control Volume Choices

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

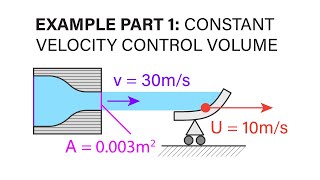

Another thing what we do is that when you define the control volume, the control surface and the velocity should align to that.

Detailed Explanation

This chunk discusses the importance of aligning the control surface with the flow velocities when defining a control volume. Ideally, the normal vector of the control surface should have a direct relationship (0 degrees or 180 degrees) with the velocity vector. When this alignment occurs, calculations simplify because the scalar product of these vectors is straightforward. Finding an optimal configuration enhances the efficiency of analysis and leads to clearer results.

Examples & Analogies

Consider a river with a current flowing smoothly in one direction. If you want to measure the speed of the water at a certain point, placing your measuring device directly in line with the current will give the most accurate reading. However, if your device is placed at an angle to the current, you’ll have to make complex calculations to understand how fast the water is truly moving. Just like this example, in fluid mechanics, aligning the control volume with the flow direction maximizes the accuracy and efficiency of your analyses.

Summary and Practical Application

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, the pressure forces can be ignored at the outlet where the fluid is discharged at subsonic velocity to the atmosphere.

Detailed Explanation

In this final chunk of the section, we conclude by noting that under certain conditions—in particular, when fluid discharges at subsonic velocities—pressure forces acting at the outlet can often be neglected. This is important for simplifying analyses, as knowing when to ignore specific forces allows engineers to focus on more significant factors affecting flow and pressure dynamics. This type of simplification is particularly useful in civil and mechanical engineering applications.

Examples & Analogies

Imagine opening a soda can. When you pop the tab, the soda discharges quickly into the air. The pressure in the can is what forces the liquid out. However, once the soda is outside, particularly in a gentle pour (or subsonic conditions), the immediate atmospheric pressure doesn't affect it significantly. In engineering terms, understanding when to neglect such forces helps streamline your calculations.

Key Concepts

-

Control Volumes: Defined areas of analysis in fluid mechanics, crucial for analyzing flow and forces.

-

Stress Tensors: Mathematical model representing stress states in fluids, comprising normal and shear stresses.

-

Body Forces: Forces acting throughout the fluid's volume, such as gravitational or magnetic forces.

-

Surface Forces: Forces acting on the surface of the fluid, crucial for understanding pressure and viscosity effects.

-

Gauge Pressure: The pressure relative to atmospheric pressure, often used in fluid calculations.

Examples & Applications

Example 1: When analyzing the water flow through a pipe, we use a cylindrical control volume around the pipe to integrate surface pressure forces and body forces (gravity) that act on the water.

Example 2: In a dam scenario, choosing a control volume that encompasses the water and the dam-structure helps assess stress distributions and overall stability due to hydrostatic forces.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Control volumes we must define, for fluid flow analysis to align.

Stories

Imagine a river flowing through a valley. To measure the forces at play, an engineer sets up a control volume at the river's mouth—by observing the forces and flow patterns, they analyze how the river affects the valley.

Memory Tools

B.S.S.G - Remember; Body forces, Surface forces, Stress tensors, and Gauge pressure.

Acronyms

C-Volume

Control Volume - area analyzed; Stress T - stress tensor; B.F - Body Force; S.F - Surface Force; G.P - Gauge Pressure.

Flash Cards

Glossary

- Control Volume

A defined region in space used to analyze fluid flow and its associated forces.

- Stress Tensor

A mathematical representation of stress at a point within a fluid, encompassing normal and shear stresses.

- Body Force

A force acting throughout the volume of a substance, such as gravitational force.

- Surface Forces

Forces acting on the surface area of a fluid, such as pressures and viscous forces.

- Gauge Pressure

The pressure that is measured relative to the atmospheric pressure.

- Absolute Pressure

The total pressure at a point, including the atmospheric pressure.

Reference links

Supplementary resources to enhance your learning experience.