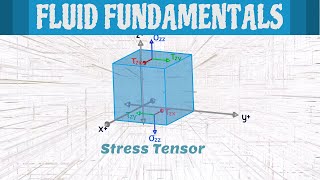

Surface Forces and Stress Tensors

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Surface Forces

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we're going to explore surface forces defined as stress tensors. Can anyone tell me what a stress tensor represents?

Isn't it just a way to describe forces acting on a surface?

Exactly! Stress is defined as force per unit area. So the stress tensor encapsulates the various forces acting on a surface. It has nine components to represent different directions and types of stresses.

So, how do those components relate to normal and shear stresses?

Great question! The diagonal components are what we call normal stresses, while the off-diagonal ones reveal shear stresses, which are influenced by viscosity. Remember this with the acronym 'N'S VS 'S' for Normal Stresses and Shear Stresses.

Got it! What about how we actually calculate forces using these tensors?

We use the scalar product of the stress tensor and normal vectors to resolve the forces acting on a control volume.

To conclude, stress tensors elegantly describe forces in engineering, allowing us to analyze and solve complex fluid mechanics problems.

Application and Benefits of Stress Tensors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dig deeper into how we apply stress tensors in engineering. Can anyone explain what a control volume is?

Isn't it the region of interest we analyze to understand fluid behavior?

Exactly! In a control volume, we consider both surface forces and body forces. What might be an example of a body force?

Absolutely! And importantly, we often neutralize atmospheric pressure in our calculations since it acts uniformly and cancels out in integrals.

How do we incorporate these forces when solving problems?

Through the use of volume and surface integrals. It's essential to break down forces into measurable parts, like pressure and viscous forces.

In summary, stress tensors and control volumes are foundational tools in analyzing fluid mechanics effectively. They provide a comprehensive framework for making sense of complex forces and behaviors.

Simplifying Assumptions in Engineering

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Simplifications are key in engineering. When we analyze a system, how can we simplify our calculations of stress tensors?

We can ignore forces that are not significant, like neglecting viscous forces when they’re small.

Correct! This allows us to focus on the main contributors to stress in our systems. Can anyone think of another scenario where we make this simplification?

When dealing with atmospheric pressure, we often only consider gauge pressure, right?

Exactly! Atmospheric pressure’s uniform effect cancels out in our force balance, allowing us to concentrate on gauge pressure for our calculations.

What about when we have multiple forces acting?

Excellent point! By isolating pressure forces from viscous forces and analyzing them separately, we can simplify complex problems. Remember to approach each scenario strategically.

To wrap up, recognizing when to simplify assumptions critically enhances our ability to solve engineering problems efficiently.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section explains that surface forces can be defined as stress tensors, comprising nine components reflecting normal and shear stresses. It details the importance of the scalar product between stress tensors and normal vectors for analyzing forces within a control volume, including insights on body force components and simplifications applicable to specific engineering problems.

Detailed

In this section, we delve into the nature of surface forces and their representation through stress tensors. By defining stress as force per unit area, we establish that a stress tensor has nine components, reflecting both normal and shear stresses. The notation parallels that used in solid mechanics, indicating the stress acting in different directions with respect to a defined coordinate system.

We highlight that the diagonal components of the tensor are related to normal stresses, which combine pressure and viscous forces, while the off-diagonal components represent shear stresses, primarily resulting from viscous effects. The practical application of these stress tensors is then explored through mathematical operations, particularly the scalar product between stress tensors and normal vectors, leading towards the computation of forces acting on control volumes.

The discussion extends to the significance of body forces, such as gravitational forces, alongside surface forces, and how these interact within fluid systems. Furthermore, we simplify our understanding of pressure forces, elucidating how atmospheric pressure cancels out in many scenarios, allowing us to focus on gauge pressure in calculations. The section illustrates how control volume selection is critical in problem-solving, emphasizing the artistic aspect of engineering practice.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Stress Tensors

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, if you come back to the surface forces, like for example, for tetrahedral structures like this where you have dx, dy, and dz components are there, and your axis is like this, x direction, y direction, and z direction. So, you can define the surface forces as a stress tensor. Stress means what, force per unit area. So, you can define as a stress tensor.

Detailed Explanation

Stress tensors are mathematical constructs used to describe internal forces within a material. They relate to how forces are distributed over an area. In this case, stress can be viewed as the force acting per unit area, which gives us insight into how materials will react under load. Specifically, stress tensors incorporate three dimensions: x, y, and z, where the components of stress can change depending on the direction and nature of forces applied.

Examples & Analogies

Think of a sponge being squeezed from different directions. The way the sponge responds, stretching this way or that, can be understood using stress tensors. Each direction of squeeze corresponds to a different component of stress within the sponge.

Components of Stress Tensors

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, this stress will have nine components. You could have this knowledge in solid mechanics. I am just repeating it. There is not much difference between solid mechanics and fluid mechanics when you consider at stress level.

Detailed Explanation

A stress tensor consists of nine distinct components that describe the stress state of a material in three-dimensional space. These components are organized in a 3x3 matrix format, where each element represents a specific type of stress. The diagonal components symbolize normal stresses (force per unit area acting perpendicular to the surface), while the off-diagonal elements convey shear stresses (force per unit area acting parallel to the surface). This framework helps engineers and scientists in both solid and fluid mechanics to analyze how forces affect materials.

Examples & Analogies

Imagine stretching a rubber band. The central part of the band experiences tension (normal stress) while the parts under your fingers experience shear. By mapping these forces out across all dimensions, we can better understand the rubber band’s behavior under stress.

Normal and Shear Stress Components

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, we have stress tensors in order to describe all surface force components. That is what will have nine components which will have, as you know the subscript describes that. The stress in the z direction acting on the face whose normal is eight directions. This is similar notation to what we use in solid mechanics.

Detailed Explanation

Stress tensors help categorize forces acting on different surfaces of a structure. Normal stress refers to stress acting perpendicular to a surface—such as pressure in a fluid—whereas shear stress acts parallel to the surface and indicates how layers of a material slide past one another. This distinction is crucial when analyzing how objects will deform or fail under different loading conditions.

Examples & Analogies

Think about squeezing a filled balloon. The pressure inside exerts normal stress, trying to expand the balloon outward. If you were to twist the balloon, you would create shear stress as different parts of the balloon slide against each other.

Calculating Total Forces

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Surface force acting on a differential surface element. Now, if I have the stress component there and I have the normal vectors, if I resolve the force components, I will have the scalar product between the stress tensor and the n vectors.

Detailed Explanation

In order to analyze forces acting on a particular area, it is essential to resolve the stress components using mathematical operations such as the scalar product. Here, the stress tensor’s interaction with the normal vectors of surfaces allows us to compute the total force acting on that surface. This is fundamental in engineering to ensure structures can withstand operational loads without failure.

Examples & Analogies

If you think about pushing a door open, the force you apply to the door contextually relates to the internal stresses in the doorframe. The concept of resolving that push into effective stress allows engineers to predict whether the door may break or remain functional.

Understanding Body Force Components

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The body force component will have volume integrals of rho g dV, g is the vector quantity as we consider the g, acceleration due to gravity can have a vector commodity with three scalar components of g_x, g_y, g_z.

Detailed Explanation

Body forces are those that act throughout the volume of a body rather than on its surface (e.g., gravitational forces). When analyzing structures, engineers often calculate these forces using integrals over the volume of the material to find how much force is being exerted internally due to gravity or other distributed forces. The components of this force can be broken down into their vector components to simplify calculations.

Examples & Analogies

Imagine a cube of jelly placed on a table. The jelly experiences a downward force due to its weight even when no one is touching its surface. The gravitational pull affects all parts of the cube uniformly, demonstrating how body forces work.

Control Volume and Pressure Distribution

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When you apply a linear momentum equations to a control volume, like I have the control surface like this, if you look at this control surface, in these three phases we have the pressure is atmospheric pressure.

Detailed Explanation

When applying momentum equations to a 'control volume' (a defined region of space to analyze), it’s crucial to consider how atmospheric pressure and internal pressures at various surfaces exert influence. In many scenarios, especially in fluid dynamics, atmospheric pressure cancels out due to equal distribution on a closed surface, simplifying our calculations. This is particularly important when analyzing systems at equilibrium, like fluids in tanks.

Examples & Analogies

Consider a sealed water bottle submerged underwater. While the water pressure on the outside attempts to crush the bottle, the atmospheric pressure inside counteracts it. This balance simplifies how we understand pressures acting on the bottle's surface.

Key Concepts

-

Stress Tensor: A mathematical construct used to represent stress variations in a fluid or solid.

-

Normal Stress: The component of stress acting perpendicular to the surface.

-

Shear Stress: The component of stress acting parallel to the surface, primarily caused by viscosity.

-

Control Volume: A defined space for analyzing fluid flow and force interactions within fluid mechanics.

Examples & Applications

In a fluid flowing through a pipe, the stress tensor is used to calculate how pressure and shear forces act on the pipe walls.

When analyzing a dam, engineers use control volumes to assess the forces acting on both the fluid and the structure.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Stress tensors here and there, normal stresses everywhere!

Stories

Imagine a water pipe in which the pressure pushes on the walls, defining stress tensors that help engineers design strong, safe systems.

Memory Tools

N'S VS 'S' to remember: Normal Stresses (N) versus Shear Stresses (S).

Acronyms

CV for Control Volume.

Flash Cards

Glossary

- Stress Tensor

A mathematical representation that describes stress as a function of force per unit area in multiple dimensions.

- Normal Stress

Stress that acts perpendicular to the surface, comprising both pressure and viscous components.

- Shear Stress

Stress that acts parallel to the surface, primarily resulting from viscosity.

- Control Volume

A defined region in space used for analyzing mass and energy transfer within fluid systems.

Reference links

Supplementary resources to enhance your learning experience.