Dimensional Analysis of Pipe Flow

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Pipe Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss the design of pipe systems for water supply. Can anyone tell me why understanding energy losses in pipes is important?

I think it helps to ensure that water reaches its destination effectively.

Exactly! Energy losses, especially due to head loss, can affect the flow rate. What are some factors that contribute to these losses?

Pipe diameter, length, and possibly the roughness of the pipe surface?

Correct! These factors play a crucial role, and understanding them through dimensional analysis allows engineers to design more efficient systems.

Dimensional Analysis and Fluid Characteristics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive into dimensional analysis. Can anyone explain what dimensional analysis helps us quantify?

It helps compute relationships between different physical quantities, like pressure and velocity.

Right! It helps us define key relationships, like the friction factor, which is essential in calculating head loss in turbulent flows. What is the friction factor dependent on?

It depends on Reynolds numbers and the roughness of the pipe divided by its diameter.

Well done! This relationship allows us to predict how the flow behaves under different conditions.

Understanding Friction Factors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss friction factors. Why are they significant in our analysis?

They indicate how much energy is lost due to friction as fluid flows through the pipe.

Exactly! And remember, as roughness increases, so does the friction factor, which leads to more energy losses. Can anyone name a way to visualize this relationship?

The Moody Chart! It shows how friction factors vary with different Reynolds numbers and roughness.

Great point! The Moody Chart is a vital tool in practical applications.

Nikuradse's Experiments and Real-World Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

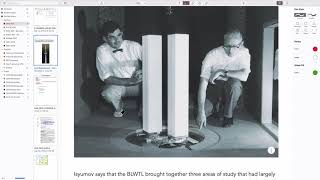

Finally, let’s talk about Nikuradse's experiments. What was his contribution to our understanding of pipe flow?

He conducted experiments to determine how roughness affects friction factors.

Exactly! And this data allows us to understand the transition from laminar to turbulent flow. How does this influence our design of pipes?

It helps in selecting the right materials and diameters to minimize energy losses.

Exactly! The right design can significantly improve system efficiency.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section delves into designing pipe systems for water supply, exploring factors like head and energy losses in turbulent flows. It introduces dimensional analysis as a tool for assessing how pipe geometry and flow characteristics influence friction factors and overall losses.

Detailed

In this section, we explore how to design efficient pipe systems for water supply, emphasizing the importance of understanding energy losses in turbulent flows. Dimensional analysis is essential in determining how variables like pipe diameter, length, viscosity, average velocity, and roughness affect pressure drops. By applying Bernoulli’s equation, we can quantify head losses, leading to a better understanding of energy availability at various points in the system. Key concepts include Reynolds numbers, friction factors, and their dependence on pipe geometry and roughness. Experimental data, including Nikuradse's experiments and Moody's charts, are discussed to illustrate the relationship between friction factors and flow characteristics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Pipe Flow Analysis

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So what they did is that to design these pipe systems like for example, we have water supply systems. There could be a source and a pipe network supplying water to different locations. These pipe networks can be complex. How do we design these pipe networks?

Detailed Explanation

This chunk introduces the concept of pipe flow systems, particularly in the context of water supply networks. It highlights that these systems can be complex due to the various paths water can take. Proper design is crucial for efficiency, ensuring that enough water, or adequate energy, reaches its destination. Understanding how to measure and manage energy losses in pipe networks is essential for effective design.

Examples & Analogies

Imagine a maze where each path represents a different pipe. The goal is to ensure that a marble (representing water) reaches the end of the maze as efficiently as possible. If there are blockages or inefficiencies at certain points, the marble may not make it through. Similarly, in real life, engineers must design pipes to avoid 'blockages' or losses of energy to ensure water can flow freely to the necessary locations.

Energy Loss and Head Loss

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

We need to quantify energy losses in terms of head loss within the pipe flow systems, i.e., looking at energy loss from Bernoulli’s equations.

Detailed Explanation

This chunk emphasizes the importance of quantifying energy and head losses in turbulent flow through a pipe. The term 'head loss' refers to the loss of potential energy due to friction and turbulence as water flows through the pipe. Bernoulli's equation helps understand this relationship by relating pressure, velocity, and elevation in fluid dynamics. The idea is to measure how much energy is lost in various segments of the pipe network to predict flow behavior and ensure system effectiveness.

Examples & Analogies

Consider riding a bicycle uphill. The effort you put in (your energy) tends to be lost to friction with the ground (energy losses), and you might not reach the top. Similarly, in pipes, energy is lost due to friction with the pipe surfaces as water flows, and engineers must account for this energy loss to ensure the system is designed to work effectively.

Dimensional Analysis Fundamentals

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If there is a pressure drop along a pipe in a turbulent flow, it depends upon various quantities such as pipe diameters, length of the pipe, viscosity, average velocity, and roughness.

Detailed Explanation

This chunk identifies critical variables affecting pressure drop in turbulent flow. By conducting dimensional analysis, engineers can relate these physical quantities to understand the flow better. Pipe diameter, length, and roughness contribute to how easily water can flow through and how much energy is lost due to friction. Understanding how each factor interacts allows engineers to design more efficient systems.

Examples & Analogies

Think about a garden hose. If you use a narrow hose (small diameter), water struggles to flow through it compared to a wider hose. Similarly, in pipes, a smaller diameter may lead to more energy loss. A practical analogy is using a straw; the smaller the straw, the harder it is to drink a thick smoothie. Choosing larger diameters helps improve flow efficiency.

Pipe Surface Roughness Impact

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The roughness of pipes plays a significant role in energy dissipation, as even seemingly smooth surfaces have microscopic variations.

Detailed Explanation

This chunk highlights the importance of pipe surface roughness in flow analysis. While some pipes may look smooth, they contain small imperfections that disrupt smooth flow, increasing turbulence and energy loss. Understanding how surface roughness interacts with flow characteristics is crucial for accurate predictions of energy efficiency.

Examples & Analogies

Imagine sliding down a slide; a smooth slide feels different from a slide with bumps. The bumps create more resistance and slow you down, similar to how a pipe's rough surface creates turbulence and energy loss in flowing water. Engineers strive for smooth surfaces to enhance efficiency, just like seeking the best slide for a fun ride.

Understanding Friction Factors

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Friction factors, influenced by Reynolds numbers and roughness, help quantify energy loss in pipe flow, particularly through relations established in experimental studies.

Detailed Explanation

This chunk introduces friction factors as a crucial aspect of dimensional analysis. These factors help determine how much energy is lost due to friction in a pipe flow. The relationship between friction factors, Reynolds numbers (which indicate the flow tendency to be laminar or turbulent), and the roughness of the pipe surface provides a formula necessary for predicting energy losses. Engineers rely on this information to calculate head loss using the Darcy-Weisbach equation effectively.

Examples & Analogies

Consider driving a car. You can accelerate smoothly on a flat highway, but if the road gets rough, you experience bumps and may lose speed (similar to energy loss due to friction). The friction factor relates closely to the car's performance based on how smooth the road is, just as it relates to how efficiently water flows through a pipe.

Practical Applications Using Moody Chart

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Moody’s chart is used for real-world applications to estimate friction factors based on Reynolds numbers and relative roughness.

Detailed Explanation

This chunk covers the practical use of Moody’s chart, a graphical representation of friction factors based on experimental data. It enables engineers to predict energy losses in various pipes accurately by inputting known values such as fluid properties and pipe dimensions, allowing them to design efficient systems that manage energy loss effectively.

Examples & Analogies

Think of a recipe for baking a cake. Just as a baker uses specific measurements of ingredients based on the type and size of the cake, an engineer uses the Moody chart to determine the optimal friction factors needed to design a pipe system effectively, ensuring every variable is appropriately accounted for to achieve the desired outcome.

Key Concepts

-

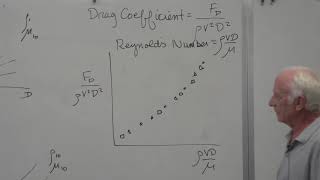

Dimensional Analysis: A method used to study the relationships among different physical quantities.

-

Energy Loss: Refers to the loss of mechanical energy due to friction in a fluid flow.

-

Friction Factor: A crucial aspect in calculating head loss in pipelines, influenced by flow conditions and pipe roughness.

Examples & Applications

In a water supply system, increasing the diameter of a pipe can lead to reduced energy loss due to friction, enhancing flow efficiency.

Nikuradse's experiments demonstrate how various types of roughness in pipes affect friction factors, ultimately influencing design choices.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In pipes that flow, energy will go; roughness is key, to know how it will be.

Stories

Imagine a race between smooth and rough pipes. The smooth one glides quickly, while the rough one slows down due to bumps—this illustrates energy loss in fluid dynamics.

Memory Tools

FALL: Friction, Area, Length, Loss—remind yourself of the factors affecting head loss.

Acronyms

R.E.L.A.T.E.

Reynolds number

Energy loss

Loss coefficient

Area

and Turbulence effects.

Flash Cards

Glossary

- Head Loss

The loss of energy or pressure in a fluid flow caused by friction and turbulence.

- Reynolds Number

A dimensionless number that determines the flow regime of the fluid, indicating whether it is laminar or turbulent.

- Friction Factor

A dimensionless quantity used in the Darcy-Weisbach equation to describe the resistance to flow due to friction.

- Moody Chart

A graphical representation of the relationship between the friction factor, Reynolds number, and relative roughness.

- Turbulent Flow

A regime of fluid flow characterized by chaotic changes in pressure and velocity.

Reference links

Supplementary resources to enhance your learning experience.