Compaction in Layered Pavement System

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Subgrade Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start by understanding subgrade compaction. Why do you think it's important in a pavement structure?

Is it because it supports the weight of everything above it?

Exactly! The subgrade must be compacted to at least 90–95% of the Modified Proctor Maximum Dry Density. This ensures that it's stable and can prevent settlement. Remember the acronym MDD—Maximum Dry Density— to help you recall this important point.

What happens if the subgrade isn’t compacted properly?

Great question! Inadequate compaction can lead to uneven settling and damage to the pavement above. This can cause costly repairs down the road.

Subbase and Base Course Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about subbase and base course compaction. How do you think it differs from subgrade compaction?

I guess it needs to be even tougher because it carries more weight, right?

Correct! These layers receive higher compactive efforts to ensure proper load distribution and support. Just remember 'high effort for high load!'

Do we still use MDD here?

Yes, but the standards can vary. For subbase and base courses, you typically aim for 95–100% of MDD to ensure optimum stability.

Compaction of Asphalt Layers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let's discuss asphalt layer compaction. Why is temperature important during this process?

Is it because the asphalt needs to be in the right state to compact properly?

Exactly! Asphalt should be compacted within a temperature range of 120–150°C to ensure it’s workable. Remember, 'Hot to trot for optimum compaction!'

What equipment is usually used for this?

Great question! We often use tandem rollers and pneumatic rollers for asphalt compaction. They help in achieving optimal density, vital for pavement longevity.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section elaborates on the objectives and methods of compaction within layered pavement systems. It highlights the significance of compaction for ensuring the structural integrity and longevity of roadways by addressing the specific compaction requirements for subgrade, subbase, and asphalt layers.

Detailed

Detailed Summary

Compaction is a critical procedure in the layered pavement system that ensures the stability and durability of roads. This section explains that:

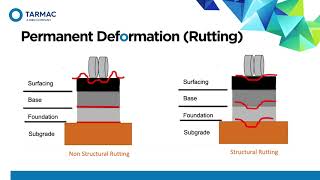

- Subgrade Compaction: The subgrade acts as the foundation of the pavement, requiring compaction to at least 90–95% of the Modified Proctor Maximum Dry Density (MDD). This density is essential to prevent future settlement and provide a stable base for the upper layers.

- Subbase and Base Course Compaction: Compared to the subgrade, these layers necessitate higher compactive efforts to effectively distribute loads and support the surface layer. The compaction of these layers is crucial for ensuring that the pavement performs as intended under traffic loads.

-

Compaction of Asphalt Layers: Asphalt is compacted using specific equipment like tandem rollers and pneumatic rollers. The compaction must occur within controlled temperature ranges (approximately 120–150°C) to achieve optimal compaction characteristics. This is vital because the performance of the pavement can be significantly affected by how well the asphalt is compacted.

Overall, proper compaction within the layered pavement system enhances structural integrity, minimizes future repairs, and extends the pavement's life.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Subgrade Compaction

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Subgrade Compaction

• Forms the foundation of the pavement.

• Compacted to minimum 90–95% of MDD.

Detailed Explanation

The subgrade is essentially the lowest layer of any pavement structure. To provide a solid and reliable foundation for the layers above it, the subgrade needs to be compacted effectively. Achieving a compaction level of at least 90–95% of the Maximum Dry Density (MDD) ensures that the subgrade can support the loads from the traffic above without excessive settlement or deformation over time.

Examples & Analogies

Think of the subgrade like the base of a tall building. If the ground is not properly compacted, the building might settle unevenly or even tip over, similar to how a poorly compacted subgrade can lead to pavement cracks and failures.

Subbase and Base Course

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Subbase and Base Course

• Receive higher compactive efforts.

• Ensures load distribution and surface support.

Detailed Explanation

The subbase and base course are layers situated above the subgrade. These layers undergo compaction with greater effort compared to the subgrade, which helps distribute the weight of traffic more evenly across the pavement structure. Effective compaction in these layers is critical because it provides the necessary support and rigidity for the asphalt or concrete surface that will be laid on top.

Examples & Analogies

Consider the subbase and base course like the layers of a cake. Each layer must be firm enough to hold the cake together so that when it's sliced, it doesn't crumble. Similarly, these layers support the overlying pavement layers to prevent failures during usage.

Compaction of Asphalt Layers

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Compaction of Asphalt Layers

• Asphalt is compacted using tandem rollers and pneumatic rollers.

• Achieved within specific temperature ranges (approx. 120–150°C).

Detailed Explanation

Once the asphalt is laid, it must be compacted to remove air voids and achieve the desired density and strength. This compaction is typically performed using tandem rollers (which have two drums) and pneumatic rollers (which use air-filled tires). It's crucial that the compaction occurs at specific temperature ranges, generally between 120°C and 150°C, because if it's too cool, the asphalt won't compact properly, leading to poor performance, while excessive heat can make it too soft and prone to deformation.

Examples & Analogies

Think of the asphalt compaction process like rolling out pizza dough. If the dough is too cold, it won’t flatten well, and if it’s too warm, it may stretch and lose shape. Similarly, the temperatures at which asphalt is compacted are key to maintaining its integrity and durability.

Key Concepts

-

Subgrade: The foundation layer that must be compacted to ensure stability.

-

MDD: Critical measure for defining optimal compaction standards.

-

Compaction of Asphalt: Needs precise temperature control for effective workability.

Examples & Applications

In highway construction, subgrade is compacted to 90-95% MDD to avoid settlement issues.

During the asphalt layer compaction, if the temperature is too low, proper density cannot be achieved, leading to future cracking.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For stable ground, compact it right, subgrade’s strength will be quite a sight!

Stories

Imagine building a house on shifting sands. You need a solid, compact foundation—just as you need a well-compacted subgrade for a strong pavement!

Memory Tools

Remember 'S-M-C' for Subgrade, MDD, and Compaction—key elements for a strong pavement foundation.

Acronyms

MDD

Maximum Density Determines performance!

Flash Cards

Glossary

- Subgrade

The layer of soil or rock that serves as the foundation for a pavement surface.

- Modified Proctor Maximum Dry Density (MDD)

The maximum density obtainable by compacting soil at its optimum moisture content in a standardized manner.

- Subbase

The layer of material placed directly on the subgrade, which provides structural stability to the pavement.

- Base Course

The layer of material above the subbase, which supports the surface layer of the pavement.

- Tandem Roller

A type of roller compactor that uses two connected drums to compact surface layers like asphalt.

Reference links

Supplementary resources to enhance your learning experience.