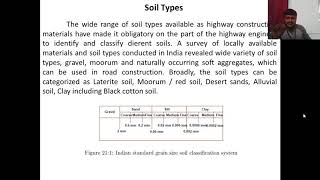

Soil Type

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

The Characteristics of Granular Soils

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s begin by discussing granular soils. Granular soils, which include sands and gravels, have particular characteristics that make them easier to compact. Can anyone tell me why they compact easily?

Is it because they have larger particles and fewer voids?

Exactly, Student_1! The larger particle size and greater intergranular friction allow for effective compaction using vibratory equipment. Remember, we can use the acronym 'GEMS' to remember Granular, Easily compacted, Mostly effective, Sands, and gravels.

What type of equipment is best for compacting these soils?

Great question! Vibratory rollers are the most effective for granular soils. They help rearrange the soil particles while reducing air voids, enhancing density.

So, is it true that water content plays a role in this?

Yes, it does! Granular soils are best compacted when they have a little water, just below the optimum moisture content. This helps lubricate the particles without creating too much suction.

What happens if there’s too much water?

Good question, Student_4! Too much water can actually reduce compaction effectiveness by creating a 'pumping' action, leading to uneven compaction. Overall, heavy use of vibratory equipment ensures the best results.

In summary, granular soils compact efficiently with vibratory methods, especially when moisture levels are just right.

Understanding Cohesive Soils

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s turn to cohesive soils, which primarily include clays and silts. Can anyone summarize how these differ from granular soils?

They are made of smaller particles and have more moisture, right?

Correct! Cohesive soils are composed of finer particles that can hold more water, leading to different compaction methods. What method would you guess is most effective for compacting these soils?

Maybe kneading or applying pressure?

Spot on, Student_2! Kneading compaction or using sheepsfoot rollers is ideal for cohesive soils. Their design applies localized pressure that compacts the soil efficiently. Remember the mnemonic 'Knead with Pressure'!

How does moisture affect these soils during compaction?

Excellent point, Student_3. Cohesive soils need to be compacted close to or slightly above their optimum moisture content to achieve maximum density. Too dry, and they remain loose; too wet, and they can become too soft.

Are there specific challenges with cohesive soils?

Definitely. They are prone to swelling and shrinkage with moisture variations, which can complicate long-term stability.

To sum up, cohesive soils require different techniques, particularly kneading compaction, and they need careful moisture management.

Grading and Its Importance in Soil Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss grading. Why is grading important in soil compaction?

Is it because it affects how well the soil compacts?

Exactly! Well-graded soils, which contain a mixture of particle sizes, can achieve better packing. This leads to higher density during compaction.

What would happen if soil is uniformly graded?

Uniformly graded soils do not compact as effectively because they contain particles of similar sizes, leading to more voids and less density. Think about it this way: packing a suitcase with clothes of all the same size versus a mixed assortment.

So, if I were to compact two different soils, one well-graded and the other uniformly graded, the well-graded one will yield better results?

Right again, Student_3! Always aim for well-graded soils when possible to optimize your compaction efforts.

So what can we do to improve uniformly graded soils?

Great question, Student_4! You can consider adding finer materials to fill the voids. This can help in achieving better density and stability.

In summary, remember that well-graded soils provide better compaction density compared to uniformly graded soils.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section describes how various soil types—granular, cohesive, and graded—affect compaction methods and efficiency. It emphasizes the characteristics of each soil type and its optimal compaction techniques.

Detailed

Soil Type in Soil Compaction

Understanding soil types is integral for effective soil compaction in construction. This section categorizes soils into two primary classifications: granular and cohesive. Granular soils, composed of sands and gravels, can be compacted easily and efficiently using vibratory equipment. In contrast, cohesive soils, such as clays and silts, require kneading or pressure compaction techniques for optimal densification.

Additionally, the grading of soils plays a crucial role in their compaction behavior. Well-graded soils—those containing a variety of particle sizes—tend to compact better than uniformly graded soils, which consist of particles of similar sizes. This knowledge assists engineers and construction professionals in selecting the appropriate compaction techniques for various soil types to ensure durability and performance in engineering applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Granular Soils

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Granular soils (sands and gravels) compact easily with vibratory equipment.

Detailed Explanation

Granular soils, which include materials like sands and gravels, are characterized by their loose structure and larger particle sizes. When compaction is applied to these soils, they respond very well, especially when using vibratory equipment. This is because the vibrations help to rearrange the soil particles closer together, allowing for efficient densification by reducing air voids between the particles.

Examples & Analogies

Think of granular soils like a bag of marbles. If you shake the bag (representing vibratory compaction), the marbles will settle closer together, leaving less space between them. This is similar to how vibratory compaction works on granular soils.

Cohesive Soils

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Cohesive soils (clays and silts) require kneading or pressure compaction.

Detailed Explanation

Cohesive soils, such as clays and silts, have smaller particles that are more tightly bound together, which makes them behave differently compared to granular soils. These soils require specific methods like kneading or pressure compaction to achieve proper densification. Kneading involves pushing and rolling the soil to break apart the bonds between particles, which allows them to pack more tightly together under pressure.

Examples & Analogies

Imagine trying to knead dough. Just like how you need to work the dough with your hands to make it firm and packed, cohesive soils need similar treatment to achieve compaction.

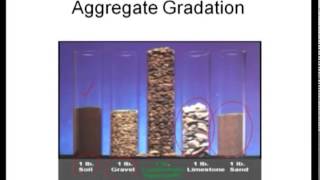

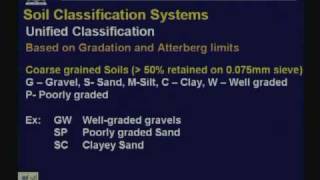

Well-Graded vs. Uniformly Graded Soils

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Well-graded soils compact better than uniformly graded soils.

Detailed Explanation

The grading of soil refers to the distribution of particle sizes within it. Well-graded soils contain a variety of particle sizes, which means that smaller particles can fill the gaps between larger particles during compaction, leading to better densification. In contrast, uniformly graded soils have a similar particle size, which results in larger voids that are not filled effectively during compaction, leading to poorer density.

Examples & Analogies

Imagine filling a box with balls of different sizes. If you start with larger balls and then add smaller balls, you'll find they fit into gaps, making the box fuller (well-graded). But, if you only use balls of the same size, there will be many gaps between them (uniformly graded). This is why well-graded soils compact better.

Key Concepts

-

Granular Soils: Characterized by larger particles; compact easily with vibratory equipment.

-

Cohesive Soils: Smaller particles that require kneading for compaction and are sensitive to moisture levels.

-

Well-Graded Soils: Have a mix of sizes leading to effective compaction; generally preferred.

-

Uniformly Graded Soils: Composed of similar-sized particles; these do not compact as well.

Examples & Applications

Granular soils can be efficiently compacted using vibratory rollers in highway construction to achieve stable and durable subgrade.

Cohesive soils, like clay, can be compacted using sheepsfoot rollers, which apply localized pressure to increase density.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Granular soils pack with ease, / Vibrating rollers work like a breeze.

Stories

Once upon a time, there were two friends: Granular Gary, easy-going and compacting under pressure, and Cohesive Claire, who needed a little warmth (moisture) to get together. Together they showed us how the right approach to soil can make the earth strong.

Memory Tools

Remember 'GC-3' to recall: Granular - Easy, Cohesive - Kneading, and 3 types of grading: Well-graded is best, Uniform not so.

Acronyms

GCC – Granular is compact, Cohesive needs moisture, Check grading for success.

Flash Cards

Glossary

- Granular Soils

Soils composed primarily of sand and gravel, known for easy compaction and good drainage.

- Cohesive Soils

Soils consisting mostly of clay and silt, requiring kneading or pressure for effective compaction.

- WellGraded Soils

Soils that contain a variety of particle sizes resulting in better density and compaction.

- Uniformly Graded Soils

Soils composed of particles of similar size, which typically have larger voids and compact less effectively.

Reference links

Supplementary resources to enhance your learning experience.