Types of Compaction Equipment

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Smooth-Wheeled Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start with smooth-wheeled rollers. These machines provide static compaction, which means they rely on their weight to compress the soil. They are quite effective for granular and semi-cohesive soils but not for thick clay layers. Can anyone think of why they might not work well on clay?

Maybe it's because they can't knead the clay?

Exactly! Clay requires a different type of compaction. We often use sheepsfoot rollers for that. Speaking of, what do you think would happen if we used smooth-wheeled rollers on thick clay?

It might leave the soil uneven or not compact it enough?

Correct! That's why we need to choose the right roller. Remember this: smooth is for smooth and granular; think of 'G-S' for Smooth-Wheeled Rollers being good for Granular Soils!

Sheepsfoot Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about sheepsfoot rollers. These rollers have lugs to knead the soil. Can anyone tell me what type of soil they're best for?

They are good for cohesive soils, right?

Yes! Cohesive soils like clays benefit from the kneading action. How do you think this helps with compaction?

It helps rearrange the particles to make them denser?

Exactly! They apply high pressure to achieve deep compaction. Remember the acronym 'SK' for Sheepsfoot Kneads the clay well!

Pneumatic Tyred Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we have pneumatic tyred rollers. Who can explain what makes them different from the other rollers we've discussed?

They have multiple rubber tyres that can adapt to different soil types?

Great observation! They’re effective for both granular and cohesive soils and provide a uniform compaction. Why do you think uniformity is essential in compaction?

To ensure the load is evenly supported?

Exactly! Based on the surface condition, they excel. So remember: 'P is for Pneumatic, Perfectly Pressing!' for their effectiveness.

Vibratory Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to vibratory rollers. What do you think vibration contributes to soil compaction?

It must help move particles around, right?

That's right! The vibrations help rearrange particles in granular soils, enhancing compaction. Can anyone name a key benefit of this type of roller?

They can adjust frequency depending on the soil?

Exactly! Dual action: they exert static weight and dynamic vibration. Remember: 'Vibratory equals Vibration Victory!'

Plate Compactors and Rammers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss plate compactors and rammers. What makes these tools unique in their application?

They're smaller and used in tight spaces like trenches?

Absolutely! Their compact size is ideal for backfills and small pavement repairs. What role do you think they play in larger projects?

I guess they help in areas where other rollers can't go?

Correct! They fill in the gaps that bigger machines cannot. Remember the mantra: 'Plate it right for the tight spaces!'

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section details five primary types of compaction equipment: smooth-wheeled rollers, sheepsfoot rollers, pneumatic tyred rollers, vibratory rollers, and plate compactors/rammers. Each type is described in terms of its operational principles, best applications, and limitations in the context of soil types.

Detailed

Types of Compaction Equipment

Soil compaction is essential in construction and infrastructure projects to ensure stability and durability. This section covers various types of compaction equipment utilized in the field:

1. Smooth-Wheeled Rollers

These rollers provide static compaction and are suitable for granular and semi-cohesive soils. However, they are not effective for thick clay layers due to their inability to exert kneading energy.

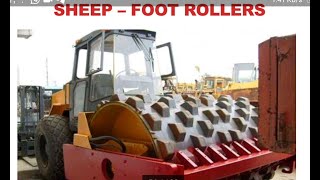

2. Sheepsfoot Rollers

Characterized by projecting lugs, sheepsfoot rollers are designed for kneading action, making them ideal for compacting fine-grained cohesive soils. The high pressure they exert helps achieve deep compaction.

3. Pneumatic Tyred Rollers

Equipped with multiple rubber tyres, pneumatic tyred rollers can compact both granular and cohesive soils effectively. They are particularly useful for achieving uniform compaction over varying surface conditions.

4. Vibratory Rollers

Utilizing vibration to compact granular soils, vibratory rollers contain adjustable drum vibration frequencies. They provide a dual action of static weight combined with dynamic vibration, making them highly effective for sands and gravels.

5. Plate Compactors and Rammers

These tools are specifically designed for use in confined spaces or trenches, making them ideal for backfills and small pavement repairs. Their compact size allows them to perform efficiently in limited areas.

Overall, selecting the appropriate equipment based on soil type and application requirements is crucial for effective soil compaction.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Smooth-Wheeled Rollers

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Provide static compaction.

• Suitable for granular and semi-cohesive soils.

• Not effective for thick clay layers.

Detailed Explanation

Smooth-wheeled rollers are heavy machines that rely on their weight to compress and compact the soil beneath them. They perform static compaction, which means they exert pressure on the soil without any vibrations. This type of equipment is effective for compacting granular soils and semi-cohesive soils, as these types can easily be densified by the downward force. However, smooth-wheeled rollers are not effective for compacting thick layers of clay because clay requires kneading action (which smooth rollers do not provide) for efficient compaction.

Examples & Analogies

Imagine a heavy person sitting on a soft couch. Their weight compresses the cushions down, making them denser. Similarly, a smooth-wheeled roller acts like this person, applying weight to compact the soil. However, just as the cushions cannot be compressed well if they are too thick for only a sitting position, thick clay layers also resist compacting when just pressed down.

Sheepsfoot Rollers

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Have projecting lugs for kneading action.

• Ideal for compacting fine-grained cohesive soils.

• High pressure per unit area helps deep compaction.

Detailed Explanation

Sheepsfoot rollers are specially designed for compacting fine-grained cohesive soils, such as clay. They have protruding lugs (or feet) on the drum surface that knead and mix the soil as the roller moves over it. This kneading action is necessary for effectively compacting cohesive soils, which tend to hold moisture and can be sticky. The high pressure exerted by the lugs helps achieve deeper compaction compared to smooth rollers.

Examples & Analogies

Think of how a chef kneads dough to make it firmer and denser. The projecting lugs of a sheepsfoot roller act like the chef's hands, working the soil to make it more compact and solid. Just as kneading dough helps its consistency, kneading the soil improves its structural integrity.

Pneumatic Tyred Rollers

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Consist of multiple rubber tyres that exert pressure.

• Suitable for both granular and cohesive soils.

• Effective in achieving uniform compaction.

Detailed Explanation

Pneumatic tyred rollers are equipped with multiple rubber tyres, which provide a flexible and forgiving surface. This allows them to exert pressure evenly across different soil types, making them suitable for both granular and cohesive soils. The flexibility of the rubber tyres helps in achieving uniform compaction and can adapt to minor variations in the surface, ensuring a consistent density throughout.

Examples & Analogies

Imagine walking on a beach with soft, wet sand. If you were to stomp around in heavy boots, you would leave deep marks in the sand. However, if you were to walk in a pair of inflatable shoes, your pressure would be distributed across a larger area, making less impact. Pneumatic tyred rollers work in a similar way, distributing their weight across multiple tyres for better soil compaction without causing too much disturbance.

Vibratory Rollers

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Use vibration to compact granular soils.

• Drum vibration frequencies can be adjusted.

• Dual action: static weight + dynamic vibration.

Detailed Explanation

Vibratory rollers operate by combining static weight with dynamic vibration, which makes them highly effective for compacting granular soils. The vibration helps rearrange soil particles, allowing them to settle closer together and thus increasing density. The adjustment of vibration frequencies can enhance the compaction process further, depending on the soil type and moisture content.

Examples & Analogies

Think of how shaking a container of sand causes the grains to settle more tightly. When you shake the container or tap it on the table, the particles rearrange into a denser formation. Vibratory rollers use a similar principle - the vibrations help the soil particles move and compact more closely together, leading to a denser and stronger structure.

Plate Compactors and Rammers

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Used in confined spaces or trenches.

• Suitable for backfills and small pavement repairs.

Detailed Explanation

Plate compactors and rammers are smaller compaction devices designed for use in confined areas like trenches or tight construction spaces where larger equipment cannot operate effectively. They are particularly useful for compacting backfill materials and making small-scale pavement repairs. Their compact size allows for precision in these limited areas while still achieving adequate compaction.

Examples & Analogies

Consider a person trying to fit a large suitcase into a tiny closet - it's simply too big. Instead, they might use smaller bags to better utilize the available space. Similarly, plate compactors and rammers are like those smaller bags; they fit into tighter spaces where larger rollers cannot, ensuring that compaction is done where it's needed most.

Key Concepts

-

Smooth-Wheeled Rollers: Effective for granular soils, not suited for thick clay.

-

Sheepsfoot Rollers: Ideal for kneading cohesive soils due to their projecting lugs.

-

Pneumatic Tyred Rollers: Versatile for both soil types and ensure uniformity during compaction.

-

Vibratory Rollers: Utilize dynamic vibrations for effective compaction of granular soils.

-

Plate Compactors: Best for confined spaces, facilitating compaction in areas where larger machines cannot operate.

Examples & Applications

A smooth-wheeled roller is best used on a gravel road, providing a flat and compact surface.

A sheepsfoot roller is effectively employed in the construction of a clay embankment, ensuring deep compaction.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Smooth wheels help compact the sands, while sheepsfoot kneads clay in hands.

Stories

Imagine a construction site where smooth-wheeled rollers glide over gravel roads, while sheepsfoot rollers dance back and forth, kneading thick clay into a solid base.

Memory Tools

Remember 'SPSV' for types: Smooth, Pneumatic, Sheepsfoot, Vibratory.

Acronyms

For 'TOC' - Types Of Compaction equipment

'S'

'P'

'S'

'V'.

Flash Cards

Glossary

- SmoothWheeled Rollers

Rollers that provide static compaction, suited for granular and semi-cohesive soils.

- Sheepsfoot Rollers

Rollers with projecting lugs used to knead and compact cohesive soils.

- Pneumatic Tyred Rollers

Rollers with rubber tyres, effective for uniform compaction of granular and cohesive soils.

- Vibratory Rollers

Machines that use vibration to compact granular soils, offering dynamic and static forces.

- Plate Compactors

Small compactors ideal for dense areas, often used in confined spaces and small repairs.

Reference links

Supplementary resources to enhance your learning experience.