Soil Compaction Techniques

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Objectives of Soil Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about the objectives of soil compaction. Can anyone tell me why compaction is important in construction?

To make the soil stronger and support more weight!

Exactly! One of the main objectives is to increase soil density and improve shear strength. Remember this with the acronym 'SIMPLE' – Strength, Increase Density, Minimize Settlement, Permeability Reduction, Load Support, and Endurance.

What does minimizing settlement mean?

Great question! Minimizing settlement means preventing the soil from sinking or shifting after it's been compacted, which can lead to problems in pavement durability.

What about water infiltration?

Reducing permeability helps prevent water from leaking through the soil, which can weaken structures. Remember, water and soil stability don't mix well!

So, how do we actually measure success in compaction?

Success can be measured by comparing in-situ densities with optimum moisture content to ensure proper compaction. That's what we will delve into next!

To summarize, the objectives of soil compaction are critical for ensuring that pavements and structures are durable, stable, and long-lasting.

Factors Affecting Soil Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss the factors that affect how well soil can be compacted. Can anyone name one?

Um, soil type?

Correct! Soil type significantly influences compaction techniques. Granular soils like sand compact easily, while cohesive soils like clay need different methods like kneading. Remember this with the term 'Gears' for Granular, Easy, And Rigid Soils.

What about moisture content?

Excellent point! Moisture content affects compaction efficiency. Each soil type achieves maximum dry density at its optimum moisture content or OMC. Too little or too much water can hinder the process.

What’s compactive effort exactly?

Compactive effort refers to the mechanical energy applied. Heavier equipment and more passes can lead to better density. Think of it as trying to pack a suitcase—more weight and effort lead to better organization!

How does layer thickness play a role?

Good question! Thinner layers can be compacted more effectively. That's just like making a cake – thinner layers rise better than thick ones. It ensures even compaction throughout.

In summary, we must consider soil type, moisture content, compactive effort, and layer thickness to optimize compaction results.

Field Compaction Methods

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's explore different field compaction methods. First, can anyone tell me what static compaction is?

Is it just using heavy weights?

Exactly! Static compaction uses the weight of the machinery directly on the soil. Suitable for cohesive soils, it doesn’t rely on movement—think of it as just 'sitting' on the surface to compress it.

What about dynamic compaction?

Dynamic compaction involves dropping heavy weights to impact the soil. It's effective for deep densification, especially in granular soils. This is like hammering a nail into wood — forcefully compacting for strength!

What are kneading and vibratory compaction?

Kneading compaction uses shearing force to rearrange particles, ideal for clays. Vibratory compaction relies on vibration, which can rearrange granular material, like shaking a box to settle its contents. Each method focuses on soil type for maximum effectiveness.

How do we know which method to use?

That depends on soil type, project requirements, and desired outcomes. Select based on soil behavior to ensure optimum compaction.

To wrap up, it’s crucial to choose the right method to achieve the best compaction results for different soil types and conditions.

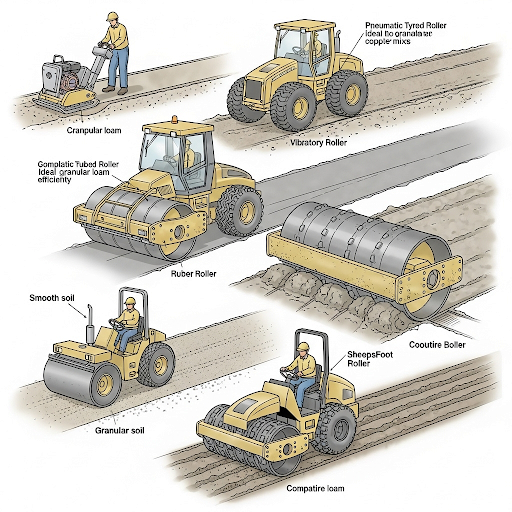

Types of Compaction Equipment

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s review some common types of compaction equipment. Can anyone name a type of roller?

Smooth-wheeled rollers?

Correct! Smooth-wheeled rollers are great for static compaction of granular and semi-cohesive soils. They apply pressure evenly, but aren't effective for thick layers of clay.

What about sheepsfoot rollers? I remember those from earlier.

Good memory! Sheepsfoot rollers have lugs that knead the soil. They apply high pressure on fine-grained soils for deep compaction. Think of the lugs as fingers kneading dough!

And what’s special about pneumatic tyred rollers?

Pneumatic tyred rollers use multiple rubber tires to exert pressure, making them perfect for both granular and cohesive soils. They optimize uniform compaction across the surface.

What are vibratory rollers used for?

Vibratory rollers use vibration for granular soil compaction. The vibrations help the particles align, a great effect!

To summarize, understanding the different types of equipment is essential for achieving optimal compaction results depending on the soil types we have.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses soil compaction as a critical process in construction, detailing its objectives, factors affecting it, methods, and equipment used. Key points include the significance of soil type, moisture content, and various compaction techniques ensuring long-term pavement performance.

Detailed

Detailed Summary

Soil compaction is a crucial process in the construction of highways and pavements. It involves the densification of soil by reducing the volume of air within its voids, which enhances its engineering properties. Key objectives include increasing soil density, improving shear strength, minimizing settlement, reducing permeability, preventing frost heaving, and ensuring the durability of pavement structures.

The section covers various factors that impact soil compaction, including soil type (granular vs. cohesive), moisture content, compactive effort, and layer thickness. Different field compaction methods—static, dynamic, kneading, and vibratory compaction—are also discussed, along with various types of compaction equipment such as smooth-wheeled rollers, sheepsfoot rollers, pneumatic tyred rollers, vibratory rollers, and plate compactors. The section concludes with an overview of field control methods for compaction, compaction of different soil types, common compaction problems and their remedies, recent advances like intelligent compaction and drone imaging, and critical points about layered pavement systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Soil Compaction

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Soil compaction is a fundamental process in highway and pavement construction that enhances the engineering properties of soil. It involves the densification of soil by reducing the volume of air within its voids, which leads to increased shear strength, reduced compressibility, and improved load-bearing capacity. Compaction ensures the long-term performance of pavements and embankments by minimizing settlements and preventing water infiltration.

Detailed Explanation

Soil compaction is crucial for improving the properties of soil used in construction. When soil is compacted, it means that the spaces filled with air between particles are reduced, making the soil denser. This process increases its strength, making it better able to support structures like roads and buildings. Moreover, properly compacted soil decreases the likelihood of settling over time, which can cause problems like cracking and uneven surfaces. It also prevents water from seeping into the soil, which can weaken the foundations.

Examples & Analogies

Think of soil compaction like packing a suitcase for a trip. When you tightly roll your clothes and fit them into the suitcase without leaving empty spaces, you maximize how much you can fit in while ensuring that everything stays put. Similarly, when we compact soil, we are making sure that everything is tightly packed together, providing a stable base for construction.

Objectives of Soil Compaction

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Increase soil density by expelling air voids.

• Improve shear strength and bearing capacity.

• Minimize settlement of soil under load.

• Reduce permeability and water infiltration.

• Prevent frost heaving and soil expansion.

• Ensure long-term durability of pavement structures.

Detailed Explanation

The main goals of soil compaction involve improving the physical properties of the soil. By removing air voids, we increase the density of the soil, making it stronger and better able to support heavy loads without settling. This process is also essential to decrease the soil’s permeability, which helps prevent water from entering the soil. Water can lead to various issues such as frost heaving and soil expansion, which can damage roads and other structures. Compaction also contributes to the longevity of pavement by ensuring it remains stable over time.

Examples & Analogies

Imagine your yard after a rainstorm. If the ground is soft and muddy, it may not hold up under the weight of patio furniture. By compacting the soil before placing heavy objects, you’re ensuring that they have a solid base and won’t sink into the ground, similar to how weightlifters ensure their footing is stable before attempting a lift.

Factors Affecting Soil Compaction

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.2 Factors Affecting Soil Compaction

3.2.1 Soil Type

• Granular soils (sands and gravels) compact easily with vibratory equipment.

• Cohesive soils (clays and silts) require kneading or pressure compaction.

• Well-graded soils compact better than uniformly graded soils.

Detailed Explanation

Different types of soil respond differently to compaction techniques. Granular soils, like sand and gravel, are loose and consist of larger particles, allowing them to compact quickly using vibratory equipment. In contrast, cohesive soils, like clay and silt, are more tightly packed and require more effort and specific techniques like kneading or pressure compaction to achieve the desired density. Additionally, well-graded soils, which have a mix of particle sizes, compact better than uniformly graded soils, leading to superior density.

Examples & Analogies

Think about packing different types of materials: if you try to pack a jar with marbles (granular soil), they fit together nicely and leave little space. But if you're packing oats (cohesive soil), you have to push them down and maneuver them a bit to fill gaps effectively, similar to how different soil types behave during compaction.

Moisture Content and Its Role in Compaction

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.2.2 Moisture Content

• Each soil type has an Optimum Moisture Content (OMC) at which the maximum dry density is achieved.

• Too little or too much water reduces compaction efficiency.

Detailed Explanation

Moisture content plays a critical role in effective soil compaction. Each type of soil has an optimal moisture level at which it compacts to its maximum possible density. If the soil is too dry, it does not stick together well, making compaction ineffective. Conversely, if there is too much water, it can create a muddy condition where the soil won't compact, and the particles cannot achieve the necessary closeness. Understanding the right balance is essential for compaction to work properly.

Examples & Analogies

Imagine trying to knead dough. If there’s too much flour, it’s dry and crumbly, so it won’t hold together well. If you add too much water, it turns sticky and won’t form a solid loaf either. There’s a sweet spot where the dough holds together beautifully, just like finding that right moisture content is key for effective soil compaction.

Laboratory Compaction Tests

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.3 Laboratory Compaction Tests

3.3.1 Standard Proctor Test (IS: 2720 Part 7)

• Determines the OMC and Maximum Dry Density (MDD).

• Soil is compacted in a 1-liter mould in three layers using a 2.6 kg rammer with 25 blows per layer.

Detailed Explanation

Laboratory compaction tests are vital for understanding soil properties before field compaction begins. The Standard Proctor Test is one way to determine the Optimum Moisture Content (OMC) and the Maximum Dry Density (MDD) of the soil. In this test, soil is placed into a mould and compacted in layers using a specific weight rammer, allowing us to identify the ideal moisture content for compaction and how dense the soil can get under optimal conditions.

Examples & Analogies

Think of this test as preparing a recipe for the perfect pancake. You start with different amounts of flour and liquid (like your soil and moisture). You make several pancakes (test compactions) until you find the right combination that produces the fluffiest and most satisfying pancake possible – similarly to how engineers test soil to find the right mixture for construction.

Compaction Equipment Overview

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.5 Types of Compaction Equipment

3.5.1 Smooth-Wheeled Rollers

• Provide static compaction.

• Suitable for granular and semi-cohesive soils.

• Not effective for thick clay layers.

Detailed Explanation

Different types of compaction equipment are used based on soil type and the required compaction method. Smooth-wheeled rollers are designed to apply pressure uniformly across the surface, making them effective for compacting granular and semi-cohesive soils. However, they are less effective in compacting thick layers of clay that need kneading to achieve proper density. Choosing the right equipment based on the soil type and conditions is essential for achieving efficient compaction.

Examples & Analogies

Imagine a painter using a roller versus a brush. A roller (like the smooth-wheeled roller) is great for covering large surfaces quickly but might not work well for detailed areas that need precise control (like the thick clay). Just as the right tool makes a difference in painting, the correct compaction equipment matters in construction.

Key Concepts

-

Soil Compaction: The densification of soil by removing air voids, enhancing strength and load-bearing capacity.

-

Optimum Moisture Content (OMC): The moisture level at which soil achieves maximum density.

-

Field Compaction Methods: Techniques like static, dynamic, kneading, and vibratory used to compact soil based on its type.

-

Types of Compaction Equipment: Various machines such as rollers and compactors employed for soil compaction.

-

Factors Affecting Compaction: Soil type, moisture content, compactive efforts, and layer thickness impact success.

Examples & Applications

Static compaction is frequently used for clay soils, where heavy rollers compress the earth without movement.

Dynamic compaction involves dropping a heavy weight onto the soil, which is effective in granular soils for deep densification.

Different soils, such as using vibratory rollers for sandy soils, demonstrate the importance of matching equipment to soil type.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To compact is to squish, remove the air and make a wish, for strength and support, that’s the hitch!

Stories

Think of a big cake that needs to be packed tight; layers upon layers, not too much light. Each layer must snugly fit, for a strong cake that won’t split!

Memory Tools

Remember 'COMPASS' for Soil Compaction: C for Compactive effort, O for Optimal moisture, M for Method, P for Particle type, A for Area covered, S for Settlement, S for Strength.

Acronyms

Use 'DENSITY' to recall compaction aspects

for Density

for Engineering stability

for Natural soil types

for Shear strength

for Infiltration reduction

for Tests

for Yield effectiveness.

Flash Cards

Glossary

- Soil Compaction

The process of densifying soil by reducing air voids to enhance its engineering properties and overall stability.

- Optimum Moisture Content (OMC)

The specific moisture level at which a soil reaches its maximum dry density, allowing for optimal compaction.

- Compactive Effort

The amount of mechanical energy applied to compact soil, influencing its density.

- Granular Soils

Soils composed of coarse particles, like sands and gravels, which compact easily.

- Cohesive Soils

Soils like clays and silts, which are characterized by fine particles and require different compaction techniques.

Reference links

Supplementary resources to enhance your learning experience.