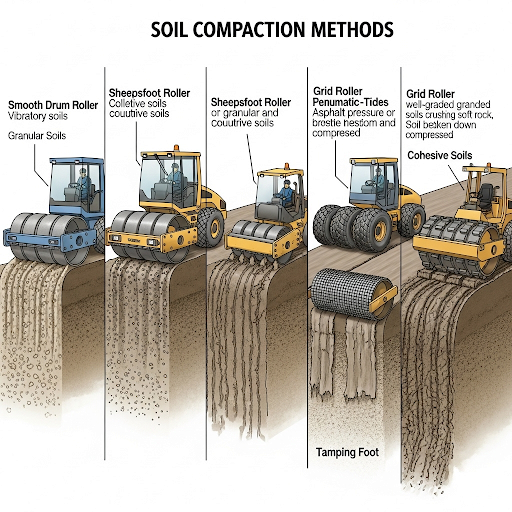

Field Compaction Methods

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Static Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about static compaction. It uses dead weight to compress soil effectively. Can anyone tell me what type of soils this method is best suited for?

I think it’s for cohesive soils.

That's correct! Static compaction is particularly useful for cohesive soils. It applies steady pressure to eliminate air voids. Now, can someone give me an example of equipment used for this method?

Smooth-wheeled rollers?

Exactly! Smooth-wheeled rollers are a common choice here. Remember the acronym SRS, which stands for Static Roller for Soils!

But what if the soil isn’t cohesive?

Great question! If the soil is granular, we might switch methods, which we'll discuss later. So, to recap, static compaction applies steady weight, making it effective for cohesive soils using rollers like the smooth-wheeled type.

Dynamic Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's discuss dynamic compaction. This method involves dropping a heavy weight from a height. What kind of soil is this technique effective for?

I think it's more suited for granular soils?

Correct! Dynamic compaction is particularly effective for granular soils. It improves deep densification. What do you think is a primary benefit of using this method?

It probably helps with the uniformity of the ground?

Exactly! The weight's impact helps achieve better ground strength. Now, how many times should the weight typically be dropped?

I guess as many times as needed to reach the required density?

Right! It’s about ensuring optimal density is reached, keeping in mind the site's specifications. Remember, dynamic compaction is effective for achieving a uniform foundation.

Kneading Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s move on to kneading compaction. This method uses shear forces to arrange soil particles. Who can tell me why this is particularly effective for cohesive soils?

I think it’s because it/shears the particles together?

Exactly, it rearranges particles, reducing voids! What equipment would you use for kneading compaction?

Sheepsfoot rollers, right?

Correct again! The sheepsfoot roller helps achieve excellent compaction. Can anyone remember how kneading compaction compares to dynamic compaction?

Dynamic compaction uses weight drops while kneading focuses on restructuring particles.

Great job summarizing that! Remember, kneading compaction is ideal for cohesive soils, using equipment like sheepsfoot rollers.

Vibratory Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s wrap up with vibratory compaction. Anyone can explain what this involves?

It uses vibration to rearrange granular soil particles.

Exactly! It’s particularly effective for sands and gravels. What type of equipment is used?

Vibratory rollers?

Right again! Additional tools include vibratory plates. Now, why is vibration so effective?

I suppose the vibrations help particles shift and settle better?

Absolutely! Vibration enhances the densification process, making this method highly efficient. So, let’s recap: vibratory compaction uses vibration to effectively compact granular soils.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section covers several field compaction methods used in soil engineering, including static, dynamic, kneading, and vibratory compaction. Each method is suitable for different soil types and conditions, emphasizing the importance of method selection for effective soil densification.

Detailed

Field Compaction Methods

Field compaction is a crucial aspect of soil engineering, directly impacting the performance and durability of construction projects. Various methods exist for compacting soil, each tailored to specific soil types and conditions. This section discusses four primary compaction methods:

1. Static Compaction

- Definition: Involves applying a steady dead weight to compress soil.

- Applications: Best for cohesive soils and smaller areas.

- Equipment Examples: Smooth-wheeled rollers and steel drum rollers.

2. Dynamic Compaction

- Definition: Involves dropping a heavy weight from a height to impact the soil.

- Applications: This technique is effective for deeply densifying granular soils before pavement construction.

- Benefits: It improves the uniformity and strength of the ground layers.

3. Kneading Compaction

- Definition: A process wherein a shearing force rearranges soil particles to achieve densification.

- Target Soil Type: Particularly effective for cohesive soils, benefiting from the dynamic manipulation of particles to eliminate voids.

- Equipment Examples: Sheepsfoot rollers and pneumatic rollers are commonly used in this method.

4. Vibratory Compaction

- Definition: Involves applying vibration to soils to induce particle rearrangement.

- Ideal Soil Types: Best suited for granular soils like sands and gravels where rearranging allows enhanced density.

- Equipment Examples: Vibratory rollers and vibratory plates.

Understanding these field compaction methods and their applications is crucial for engineers to design durable structures and ensure the stability of paved surfaces.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Static Compaction

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.4.1 Static Compaction

- Application of dead weight to compress soil.

- Suitable for cohesive soils and small areas.

- Examples: smooth-wheeled rollers, steel drum rollers.

Detailed Explanation

Static compaction involves using heavy weights to compress soil without any vibration. This method is particularly effective for cohesive soils, which are soils that stick together such as clay. The weight of the roller creates pressure that forces the soil particles closer together, eliminating air spaces and increasing density. This technique is best suited for smaller areas where less movement of the equipment is required.

Examples & Analogies

Imagine sitting down on a soft cushion. Initially, the cushion has a lot of space and feels fluffy, but as you sit down, your weight compresses the cushion, forcing the fluffy material together and making it denser. Similarly, static compaction works by applying weight to soil to make it denser.

Dynamic Compaction

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.4.2 Dynamic Compaction

- Impact of heavy weight dropped from height.

- Effective for deep densification of granular soils.

- Commonly used in ground improvement before pavement construction.

Detailed Explanation

Dynamic compaction uses the force of a heavy weight that is dropped from a height to compact the soil below. The impact creates a shock wave that rearranges the soil particles and increases their density, especially effective in granular soils like sand and gravel. This method is often implemented in situations where deep compaction is needed, such as before laying down pavements to ensure stability.

Examples & Analogies

Think about jumping onto a trampoline. If you jump from a low height, you might not go very far, but if you jump from a higher height, the impact causes a greater reaction, compressing the trampoline springs more. Dynamic compaction works similarly by dropping heavy weights from above to compress the soil effectively.

Kneading Compaction

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.4.3 Kneading Compaction

- Shearing force is applied to rearrange soil particles.

- Effective for cohesive soils.

- Equipment: sheepsfoot rollers, pneumatic rollers.

Detailed Explanation

Kneading compaction involves using equipment that applies a shearing action to the soil. This technique is particularly effective for cohesive soils and involves rearranging soil particles to push them closer together, thus increasing their density. Sheepsfoot rollers and pneumatic rollers are commonly used for this type of compaction, as their design allows them to apply both weight and kneading action on the soil.

Examples & Analogies

Consider kneading dough when making bread. As you push and fold the dough, you're compacting it and rearranging its structure to improve its consistency. Kneading compaction works in much the same way by rearranging the soil's structure, increasing its density.

Vibratory Compaction

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

3.4.4 Vibratory Compaction

- Vibration induces particle rearrangement in granular soils.

- Equipment: vibratory rollers, vibratory plates.

- Most effective for sands and gravels.

Detailed Explanation

Vibratory compaction uses a vibrating mechanism to induce rapid movement among the soil particles, helping them rearrange into a denser configuration. This method is especially effective for granular soils, including sands and gravels, as the vibrations help to overcome friction between soil particles and settle them into tighter spaces. Equipment such as vibratory rollers and vibratory plates are used for this process, providing both weight and vibration.

Examples & Analogies

Imagine shaking a container filled with marbles. If you shake it vigorously, the marbles will move around and settle down in a way that they occupy less space compared to when they are just sitting still. Similarly, vibratory compaction shakes the soil particles to promote denser packing.

Key Concepts

-

Field Compaction: A process of increasing soil density through various methods.

-

Static Compaction: Involves using a steady weight for compressing soil, effective for cohesive types.

-

Dynamic Compaction: A method utilizing impactful weights for densifying soil, particularly useful for granular types.

-

Kneading Compaction: A technique that employs shear forces to compact soil particles, especially in cohesive soils.

-

Vibratory Compaction: Uses vibration to achieve densification of granular soils.

Examples & Applications

Using a sheepsfoot roller on clay to achieve optimal density.

Applying dynamic compaction by dropping weights on sandy soil before laying a pavement.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For static weight, it's best to see, Cohesive soils gain density.

Stories

Imagine a builder with a heavy weight, dropping it down to make soil great! First, static, then dynamic, adjusting the fate!

Memory Tools

Remember 'SKDV' for compaction types: Static, Kneading, Dynamic, Vibratory.

Acronyms

Use 'SKDV' to remember the four methods of soil compaction

Static

Kneading

Dynamic

Vibratory.

Flash Cards

Glossary

- Static Compaction

The application of constant weight to compress soil, effective for cohesive soils.

- Dynamic Compaction

A method using a heavy weight dropped from a height to densify soil, effective for granular soils.

- Kneading Compaction

A method that applies shear forces to rearrange soil particles, best for cohesive soils.

- Vibratory Compaction

Utilizes vibration to rearrange and densify granular soil.

Reference links

Supplementary resources to enhance your learning experience.