Compaction of Asphalt Layers

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Asphalt Layer Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss the compaction of asphalt layers. Can anyone tell me why compaction is important for asphalt pavements?

Isn't it to make the pavement stronger and more durable?

Exactly! Compaction enhances the density of asphalt, which translates to better load-bearing capacity and a longer lifespan. Remember: 'Densified Asphalt is Stronger Asphalt'!

What kind of equipment do we use for this compaction?

Great question! We primarily use tandem rollers and pneumatic rollers. Both are designed to achieve specific compaction requirements.

What about the temperature? I have heard it's important.

Yes! Compaction should take place within a temperature range of 120 to 150°C. This ensures that the asphalt remains workable and achieves proper bonding.

What could happen if the temperature is too low during compaction?

If it's too low, the asphalt might become too stiff, leading to inadequate compaction and increased risk of cracking. Remember: 'Warm Asphalt Compresses Best!

In summary, effective asphalt compaction is crucial for constructing durable pavements that can withstand traffic loads.

Types of Compaction Equipment

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive deeper into the types of equipment used for asphalt compaction. Can anyone name one type?

Tandem rollers!

Correct! Tandem rollers have two drums and help in achieving smooth surfaces. They are effective for thinner asphalt layers.

What about pneumatic rollers?

Pneumatic rollers use air-filled tires and provide flexibility during compaction, making them ideal for irregular surfaces. They help in achieving uniform density.

So, is it better to use one over the other?

Each has its advantages. A combination often yields the best results—'Tandem for Smoothness, Pneumatic for Flexibility!'

How do we decide which one to use?

It depends on the project specifics such as layer thickness and surface conditions. Always consider the context: 'Choose the Roller for the Role!'

To summarize, both tandem and pneumatic rollers are valuable, each serving distinct roles in asphalt layer compaction.

Temperature Control in Asphalt Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s focus on temperature control in asphalt compaction. Why do you think it's critical?

Because it affects how well the asphalt binds, right?

Exactly! If the asphalt is too hot, it may lose its oils; too cold, and it wouldn't compact well.

How do we know the right temperature during compaction?

We typically monitor temperatures using thermal sensors on site. Remember: 'If You Control the Heat, You Control the Outcome!'

Is there a specific time we have to complete the compaction?

Yes, compaction should be performed as soon as possible after asphalt is laid, typically within the working temperature range. This ensures minimal cooling for optimal results.

What if the compaction is done too late?

Delaying compaction will lead to poor density and may result in permanent deformation of the asphalt layer. It's essential to act swiftly: 'Time is Density's Best Friend!'

In essence, temperature significantly impacts asphalt layer compaction and should always be monitored closely.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the processes involved in the compaction of asphalt layers, emphasizing the use of tandem and pneumatic rollers to achieve the desired density within a temperature range of 120-150°C, which is critical for the longevity and stability of pavement structures.

Detailed

Compaction of Asphalt Layers

The compaction of asphalt layers plays a vital role in the overall performance and durability of pavements. It primarily involves the use of specialized equipment, such as tandem rollers and pneumatic rollers. Compaction must be conducted at specific temperatures, typically ranging from 120 to 150°C, to ensure that the asphalt sufficiently bonds and achieves the required density. Proper compaction is crucial to enhance the pavement's ability to withstand traffic loads and to minimize issues like cracking and rutting over time. In this section, we will explore how these techniques enhance the performance and lifespan of asphalt pavements.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Asphalt Compaction

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Asphalt is compacted using tandem rollers and pneumatic rollers.

Detailed Explanation

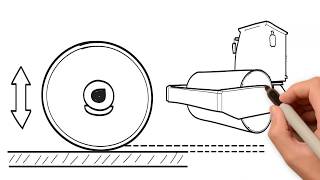

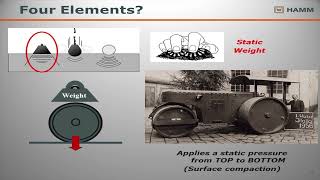

This chunk introduces the methods used for compacting asphalt during construction. Specifically, two types of rollers are mentioned: tandem rollers, which have two drums that work together to compress the asphalt surface, and pneumatic rollers, which use air-filled tires to make contact with the asphalt.

Examples & Analogies

Think of these rollers like heavy vehicles driving on freshly laid asphalt. Just as a school bus can make deep impressions on wet sand at the beach, these rollers apply significant pressure on the asphalt to ensure it is compacted and flat.

Temperature Control

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Achieved within specific temperature ranges (approx. 120–150°C).

Detailed Explanation

This chunk discusses the importance of maintaining a specific temperature range during the compaction of asphalt. The optimal temperature for compacting asphalt is between 120°C and 150°C. If the temperature is too low, the asphalt may not compact properly, leading to issues in strength and durability.

Examples & Analogies

Imagine trying to flatten a soft chocolate bar. If it's cold, it stays hard and crumbly, and you can't press it effectively. However, when it’s warm, it becomes pliable and easier to mold. Similarly, asphalt needs to be at the right temperature to be compacted effectively.

Key Concepts

-

Compaction Importance: Compaction increases asphalt density and enhances load-bearing capacity.

-

Roller Types: Tandem rollers and pneumatic rollers are the primary equipment for asphalt compaction.

-

Optimum Temperature: The compaction of asphalt is most effective at temperatures between 120-150°C.

Examples & Applications

Using a tandem roller for the initial pass to achieve a smooth surface.

Employing a pneumatic roller to achieve uniformity in compaction for irregular surfaces.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Asphalt so warm, holds its form, compact it right, keeps things tight.

Stories

Imagine a city where roads melt in heat, but with the right temperature, asphalt stands up on its feet! Proper compaction strengthens the streets, ensuring smooth travel for all who meet.

Memory Tools

D.A.P.T.: Density, Asphalt, Pneumatic, Temperature – remember these are key to asphalt compaction!

Acronyms

R.O.A.D.

Rollers Optimize Asphalt Density!

Flash Cards

Glossary

- Asphalt

A viscous material made from petroleum, used to pave and seal surfaces.

- Compaction

The process of densifying soil or asphalt by reducing air voids, enhancing structural capacity.

- Tandem Roller

A type of roller with two drums used for compacting asphalt and creating a smooth surface.

- Pneumatic Roller

A roller that uses inflatable tires to compact asphalt, providing flexibility and uniformity.

- Optimum Temperature Range

The ideal temperature range (typically 120-150°C) for effective asphalt compaction.

Reference links

Supplementary resources to enhance your learning experience.